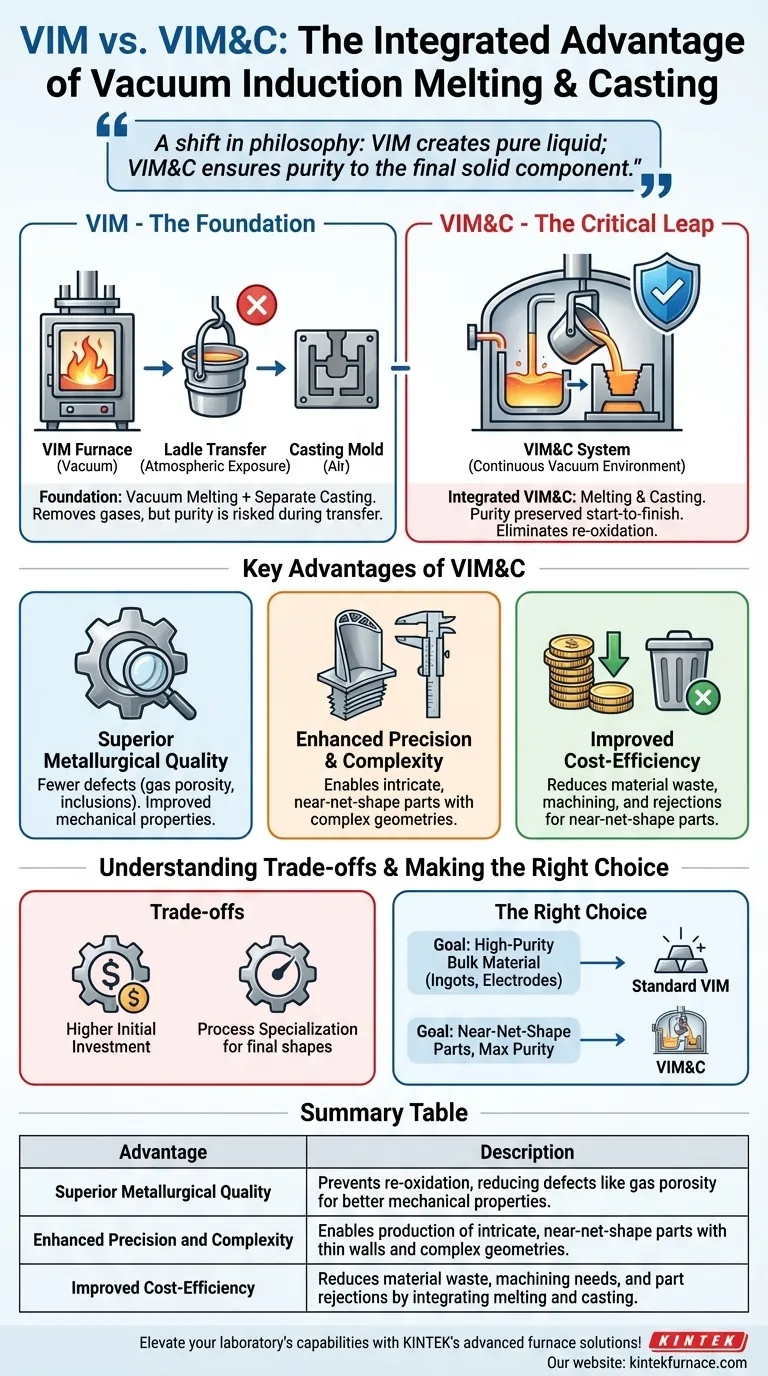

The fundamental advantage of Vacuum Induction Melting and Casting (VIM&C) is its integrated nature. While a standard Vacuum Induction Melting (VIM) process only melts metal in a vacuum to achieve high purity, the VIM&C process extends this control by also casting the metal into its final shape within the same protected vacuum environment. This single, uninterrupted process prevents the pure molten metal from being exposed to the atmosphere before it solidifies.

The core difference is not a small upgrade, but a shift in philosophy. VIM creates a pure liquid metal; VIM&C ensures that purity is preserved all the way into the final solid component, directly translating to superior quality and efficiency.

The Foundation: What is Vacuum Induction Melting (VIM)?

The Purpose of the Vacuum

Vacuum Induction Melting is a refining process used to produce metals and alloys with exceptionally high purity. The primary function of the vacuum is to remove dissolved gases, particularly oxygen and nitrogen, which are detrimental to the properties of many high-performance alloys.

The Role of Induction

The "induction" part of VIM refers to the heating method. An electric coil generates a powerful electromagnetic field, which heats and melts the metal charge without any direct contact. This prevents contamination that could occur from traditional heating elements. The result of a VIM process is a clean, pure batch of molten metal.

The Critical Leap: Integrating Casting (VIM&C)

Eliminating Atmospheric Exposure

The VIM process concludes once the metal is fully melted and refined. The "C" in VIM&C represents the crucial next step: casting. In a VIM&C system, the mold is located within the same vacuum chamber. The purified molten metal is poured directly into the mold without ever leaving the vacuum.

A Single, Controlled Workflow

This integration turns two separate processes (melting and casting) into one continuous operation. By eliminating the step of transferring molten metal in a ladle through the open air, VIM&C prevents re-oxidation and the re-introduction of gases and impurities at the most critical moment.

Key Advantages of the Integrated VIM&C Process

Superior Metallurgical Quality

By preventing contact with the atmosphere, VIM&C produces castings that are significantly cleaner. This results in a final product with fewer defects such as gas porosity and non-metallic inclusions, leading to improved mechanical properties like strength and fatigue life.

Enhanced Precision and Complexity

The controlled vacuum environment allows the molten metal to flow more easily and fill the mold cavity more completely. This enables the production of highly precise parts with intricate details, thin walls, and complex geometries that would be difficult or impossible to achieve with conventional casting methods.

Improved Cost-Efficiency

Although the equipment is more complex, VIM&C can reduce overall costs. This is achieved by eliminating the need for separate casting operations and, more importantly, by producing near-net-shape parts with a higher success rate. This drastically reduces material waste, downstream machining, and the cost of rejected parts.

Understanding the Trade-offs

Higher Initial Investment

VIM&C systems are inherently more complex than standalone VIM furnaces. They require sophisticated engineering to integrate the melting crucible and the casting mold mechanism within a single chamber, leading to a higher initial capital cost.

Process Specialization

The VIM&C process is specifically designed for creating final cast shapes. If the goal is simply to produce high-purity ingots or electrodes that will be remelted or forged later, the integrated casting component is unnecessary. In these cases, a standard VIM furnace is the more direct and economical tool for the job.

Making the Right Choice for Your Goal

Ultimately, the choice between VIM and VIM&C depends entirely on the final product you intend to create.

- If your primary focus is producing near-net-shape parts with maximum purity and minimal defects: VIM&C is the superior process, as it protects the material's integrity from start to finish.

- If your primary focus is creating high-purity bulk material (ingots, bars, or electrodes) for subsequent remelting or forging: Standard VIM provides the necessary purity for the intermediate product in a more cost-effective manner.

Choosing the right process is about matching the technology to your final objective.

Summary Table:

| Advantage | Description |

|---|---|

| Superior Metallurgical Quality | Prevents re-oxidation, reducing defects like gas porosity for better mechanical properties. |

| Enhanced Precision and Complexity | Enables production of intricate, near-net-shape parts with thin walls and complex geometries. |

| Improved Cost-Efficiency | Reduces material waste, machining needs, and part rejections by integrating melting and casting. |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored systems like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, helping you achieve superior metallurgical results and cost savings. Ready to optimize your process? Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries