The primary technical advantage of a Vacuum Induction Melting (VIM) furnace is the creation of an ultra-high-purity melting environment. By utilizing electromagnetic induction within a vacuum, this equipment isolates the molten steel from atmospheric gases like oxygen and nitrogen. This isolation is critical for preventing contamination and ensuring that the final ingot possesses the exact chemical composition required for high-performance packaging steel.

Core Insight: The VIM process removes the "noise" from your material data. By eliminating gaseous impurities and preventing the oxidative loss of alloying elements, it ensures that your research results reflect the true properties of your steel design rather than the defects of the melting process.

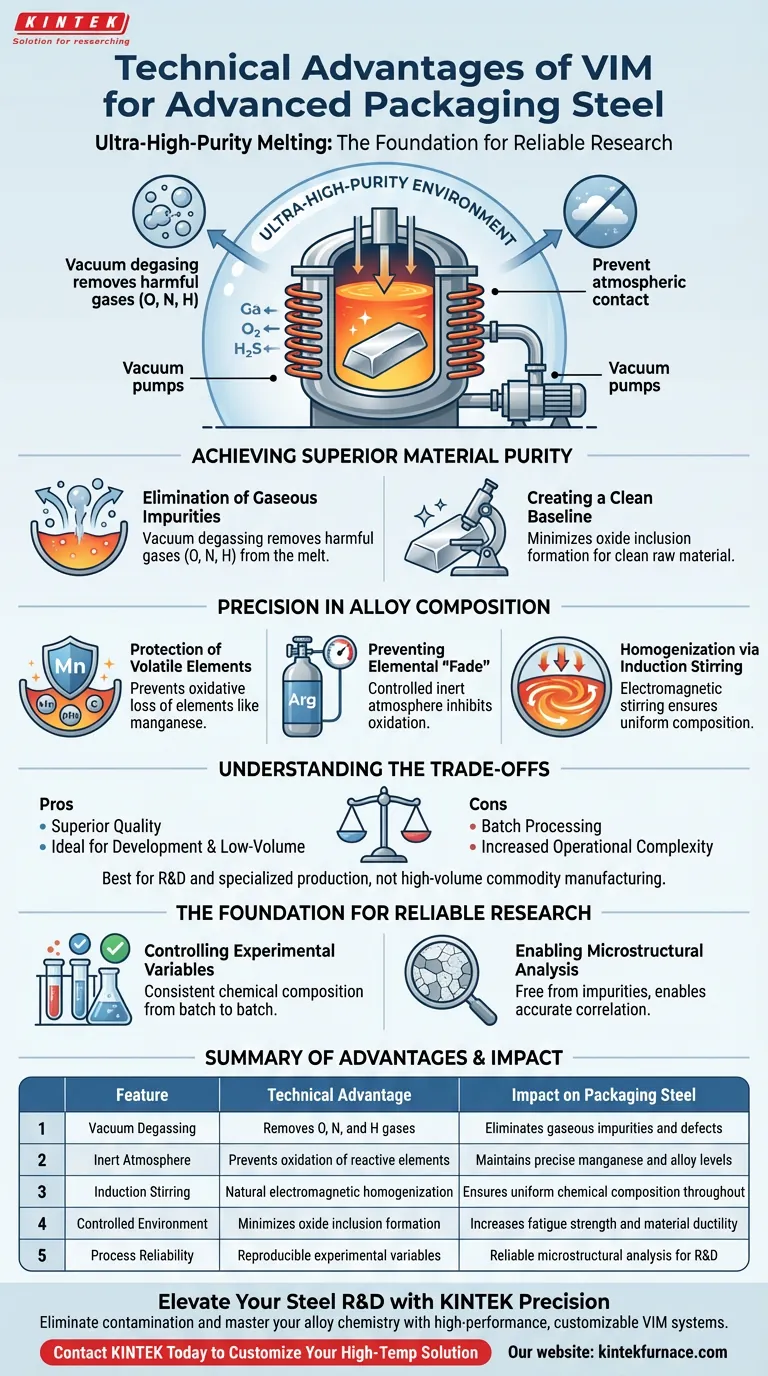

Achieving Superior Material Purity

Elimination of Gaseous Impurities

The most immediate benefit of the VIM furnace is the vacuum degassing capability. The vacuum environment actively facilitates the removal of harmful gases such as oxygen, nitrogen, and hydrogen from the melt.

Creating a Clean Baseline

By minimizing contact between the melt and the atmosphere, the furnace drastically reduces the formation of oxide inclusions. This results in a "clean" raw material base, which is essential when developing steel grades that require high fatigue strength or ductility.

Precision in Alloy Composition

Protection of Volatile Elements

Advanced packaging steels often rely on specific alloying elements, such as manganese, to achieve desired mechanical properties. In open-air melting, these elements are prone to oxidative loss.

Preventing Elemental "Fade"

The VIM furnace provides a controlled low-pressure or inert atmosphere (often argon). This effectively inhibits the oxidation of reactive elements, ensuring the final ingot matches your theoretical calculations.

Homogenization via Induction Stirring

The electromagnetic induction process does more than generate heat; it induces a natural stirring action within the molten bath. This ensures a high degree of compositional homogenization, distributing iron, carbon, and manganese evenly throughout the ingot.

Understanding the Trade-offs

Batch Processing vs. Continuous Flow

While VIM offers superior quality, it is inherently a batch process. This makes it ideal for the development phase and specialized low-volume production, but potentially less efficient for high-volume commodity manufacturing compared to continuous casting methods.

Increased Operational Complexity

Achieving high vacuum levels requires sophisticated pumping systems and strict seal maintenance. This adds a layer of operational complexity and cost that is not present in standard induction melting.

The Foundation for Reliable Research

Controlling Experimental Variables

In R&D, reproducibility is paramount. The VIM furnace ensures that the chemical composition of experimental ingots is consistent from batch to batch.

Enabling Microstructural Analysis

Because the steel is free from unintended impurities, subsequent research can accurately correlate the steel's microstructure to its performance. You can be confident that observed behaviors are due to your alloy design, not random contamination.

Making the Right Choice for Your Project

To leverage VIM technology effectively, align its capabilities with your specific development phase:

- If your primary focus is fundamental alloy design: Rely on VIM to prevent the loss of expensive or reactive alloying elements, ensuring your prototype matches your design exactly.

- If your primary focus is performance testing: Use VIM ingots to eliminate impurity-related failure modes, allowing you to isolate the intrinsic mechanical properties of the steel.

- If your primary focus is process scaling: Use VIM to establish the "gold standard" of material quality before transitioning to more cost-effective, high-volume melting methods.

High-quality input leads to high-quality data; the VIM furnace is the gatekeeper of that quality.

Summary Table:

| Feature | Technical Advantage | Impact on Packaging Steel |

|---|---|---|

| Vacuum Degassing | Removes O, N, and H gases | Eliminates gaseous impurities and defects |

| Inert Atmosphere | Prevents oxidation of reactive elements | Maintains precise manganese and alloy levels |

| Induction Stirring | Natural electromagnetic homogenization | Ensures uniform chemical composition throughout |

| Controlled Environment | Minimizes oxide inclusion formation | Increases fatigue strength and material ductility |

| Process Reliability | Reproducible experimental variables | Reliable microstructural analysis for R&D |

Elevate Your Steel R&D with KINTEK Precision

Ready to eliminate contamination and master your alloy chemistry? Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Induction Melting (VIM) systems, Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to meet your unique laboratory needs. Whether you are developing advanced packaging steel or exploring fundamental metallurgy, our equipment provides the ultra-high-purity environment required for gold-standard research.

Contact KINTEK Today to Customize Your High-Temp Solution

Visual Guide

References

- R. Uzun, Yasemin Kılıç. Effect of Chemical Composition and Annealing Parameters for Advanced Packaging Steel Applications. DOI: 10.16984/saufenbilder.1599129

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does a high-frequency heat induction furnace contribute to the sintering of Titanium-Zirconium alloys?

- How do MgO crucibles affect melt purity? Strategies for High-Purity Vacuum Induction Remelting

- What role do medium frequency induction furnaces play in heat treatment? Achieve Superior Metallurgical Properties

- What role does a vacuum induction melting furnace play in the modification of W18Cr4V steel? Enhance Alloy Purity

- What are the main advantages of vacuum melting furnaces? Achieve Ultra-Pure Metals for High-Performance Applications

- What is the function of a vacuum arc furnace in the preparation of high-entropy alloy ingots? Achieve Perfect Homogeneity

- How does an IGBT Vacuum Induction Melting Furnace operate? Achieve Ultra-High-Purity Metal Melting

- What materials are typically processed in vacuum melting furnaces? Unlock High-Purity Material Processing