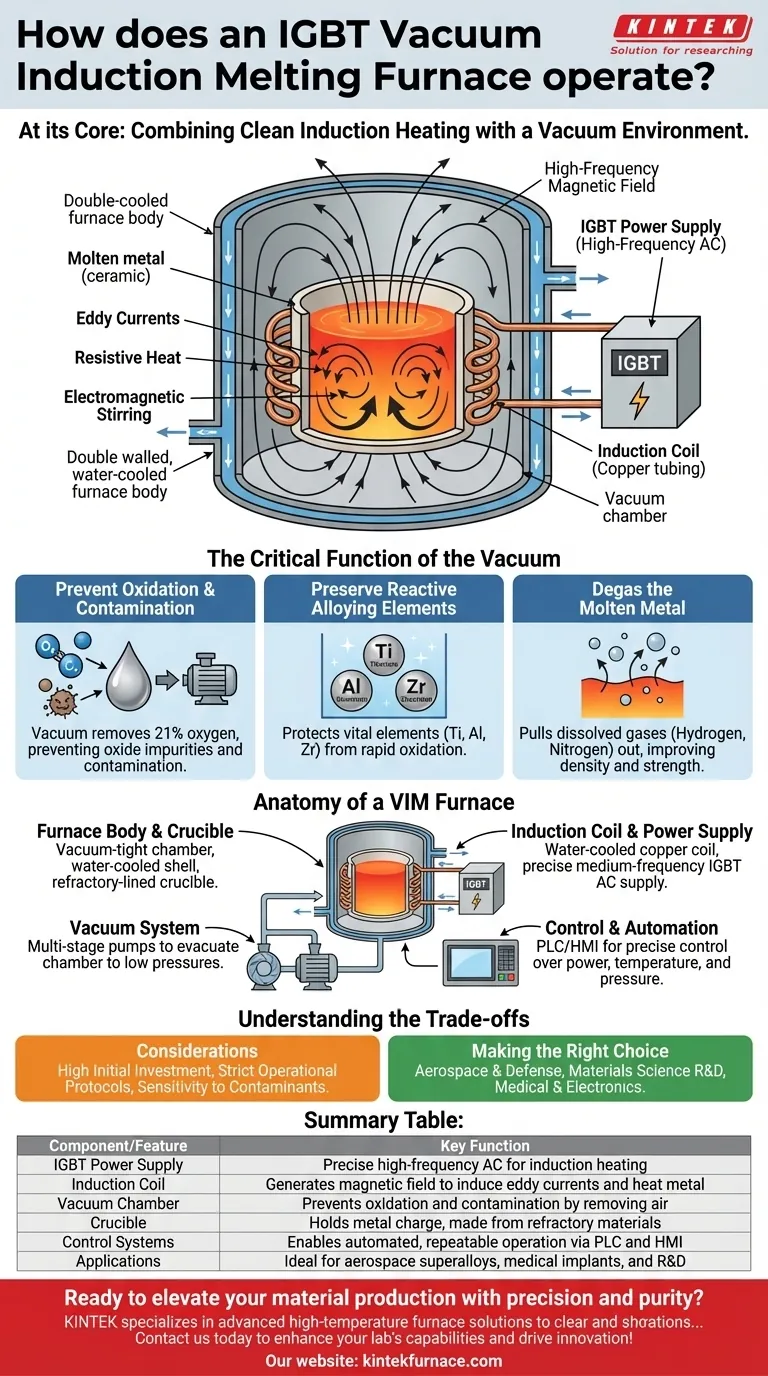

At its core, an IGBT Vacuum Induction Melting (VIM) furnace operates by using a powerful, high-frequency magnetic field to melt metals inside a vacuum chamber. The Insulated-Gate Bipolar Transistor (IGBT) power supply generates a precise alternating current in a copper coil, which in turn induces intense electrical currents within the metal itself. This process, known as electromagnetic induction, generates heat directly inside the material, while the vacuum prevents any contamination from the surrounding atmosphere.

The true value of a VIM furnace lies not just in melting metal, but in its unique ability to combine clean, efficient induction heating with a vacuum environment. This synthesis is what enables the production of the ultra-high-purity, reactive, and complex alloys required for today's most demanding technological applications.

The Core Principle: How Induction Melts Metal

The "induction" in VIM is the fundamental heating mechanism. It is a contactless process that generates heat from within the material itself, offering significant control and efficiency.

The Role of the Induction Coil

An induction coil, typically made of water-cooled copper tubing, is wrapped around the crucible that holds the metal charge. The IGBT power supply drives a high-frequency alternating current (AC) through this coil.

This AC flow generates a powerful and rapidly fluctuating magnetic field in the space occupied by the metal.

Generating Heat via Eddy Currents

According to Faraday's law of induction, this changing magnetic field induces electrical currents within the conductive metal. These are known as eddy currents.

Because metals have electrical resistance, the flow of these strong eddy currents generates immense resistive heat (Joule heating), causing the metal to quickly heat up and melt from the inside out.

The Advantage of Electromagnetic Stirring

A key benefit of induction heating is the natural stirring action it creates. The electromagnetic forces generated by the coil and eddy currents cause the molten metal to circulate continuously.

This inherent stirring ensures excellent chemical and thermal homogeneity throughout the melt, which is critical for producing high-quality, consistent alloys.

The Critical Function of the Vacuum

The "vacuum" is what elevates the VIM furnace from a simple melter to a sophisticated refining tool. By removing the air from the melting chamber, we gain precise control over the material's chemistry.

Preventing Oxidation and Contamination

Atmospheric air contains about 21% oxygen, which is highly reactive with molten metals. The vacuum environment eliminates this oxygen, preventing the formation of oxide impurities that degrade the material's properties.

It also removes other atmospheric contaminants like nitrogen and water vapor, ensuring a completely clean melting process.

Preserving Reactive Alloying Elements

Many advanced superalloys rely on highly reactive elements like titanium, aluminum, and zirconium for their unique properties. In a conventional furnace, these elements would rapidly oxidize and be lost.

The vacuum protects these vital elements, allowing for the creation of alloys with precise, on-target chemistries.

Degassing the Molten Metal

Molten metals can dissolve gases like hydrogen and nitrogen, which become trapped during solidification and create porosity or brittleness.

Pulling a vacuum over the molten bath literally pulls these dissolved gases out of the liquid metal, a critical step for improving the final material's density, strength, and fatigue life.

Anatomy of a VIM Furnace

A VIM furnace is a complex system where each component serves a distinct and vital purpose.

Furnace Body and Crucible

The core of the system is the vacuum-tight furnace chamber, often built with a double-walled, water-cooled steel shell to handle the intense internal heat.

Inside this chamber sits the crucible, a ceramic or graphite container refractory-lined to hold the molten metal.

The Induction Coil and Power Supply

The induction coil is fitted around the crucible. The entire system is powered by a medium-frequency IGBT power supply, which provides the stable, controlled, high-amperage alternating current needed for efficient melting.

The Vacuum System

A multi-stage vacuum system, consisting of mechanical roughing pumps and high-vacuum diffusion or turbo-molecular pumps, is used to evacuate the chamber to the required low pressures. A series of valves controls the pumping sequence.

Control and Automation Systems

Modern VIM furnaces are operated via a Programmable Logic Controller (PLC) and a human-machine interface (HMI), often a touch screen. This allows for precise, repeatable control over power, temperature, pressure, and pouring cycles.

Understanding the Trade-offs

While incredibly powerful, VIM technology involves specific considerations and is not a universal solution for all melting needs.

High Initial Investment and Complexity

VIM furnaces are highly specialized pieces of equipment. The cost of the furnace, the required vacuum systems, and the sophisticated power supply represents a significant capital investment.

Strict Operational Protocols

Operating a VIM furnace requires well-trained personnel. Safety procedures are paramount, including wearing appropriate personal protective equipment (PPE) and maintaining a clear, obstacle-free zone around the furnace.

Sensitivity to Contaminants

The very precision of the VIM process makes it sensitive. Operators must prevent any liquids, especially water from the cooling circuits, from coming near the furnace chamber to avoid a dangerous steam explosion.

Proper handling of inert gases like argon, which are sometimes used for partial pressure melting or backfilling, is also a critical safety skill.

Making the Right Choice for Your Application

Applying this technology effectively means matching its capabilities to your specific metallurgical goal.

- If your primary focus is aerospace or defense: VIM is the definitive choice for producing nickel-based superalloys and specialty steels for turbine blades, discs, and other critical-service components.

- If your primary focus is materials science R&D: The furnace's precise control and clean environment make it an ideal tool for developing novel alloys, intermetallics, and high-purity metals.

- If your primary focus is medical or electronics: VIM is essential for creating high-purity, biocompatible alloys like titanium for implants or the ultra-pure materials needed for semiconductor production.

Ultimately, the VIM furnace is an indispensable tool for mastering the chemistry and structure of advanced materials at the highest level.

Summary Table:

| Component/Feature | Key Function |

|---|---|

| IGBT Power Supply | Provides precise high-frequency AC for efficient induction heating |

| Induction Coil | Generates magnetic field to induce eddy currents and heat metal |

| Vacuum Chamber | Prevents oxidation and contamination by removing air |

| Crucible | Holds metal charge, made from refractory materials |

| Control Systems | Enables automated, repeatable operation via PLC and HMI |

| Applications | Ideal for aerospace superalloys, medical implants, and R&D |

Ready to elevate your material production with precision and purity? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces tailored for demanding applications. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our expertise can enhance your lab's capabilities and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification