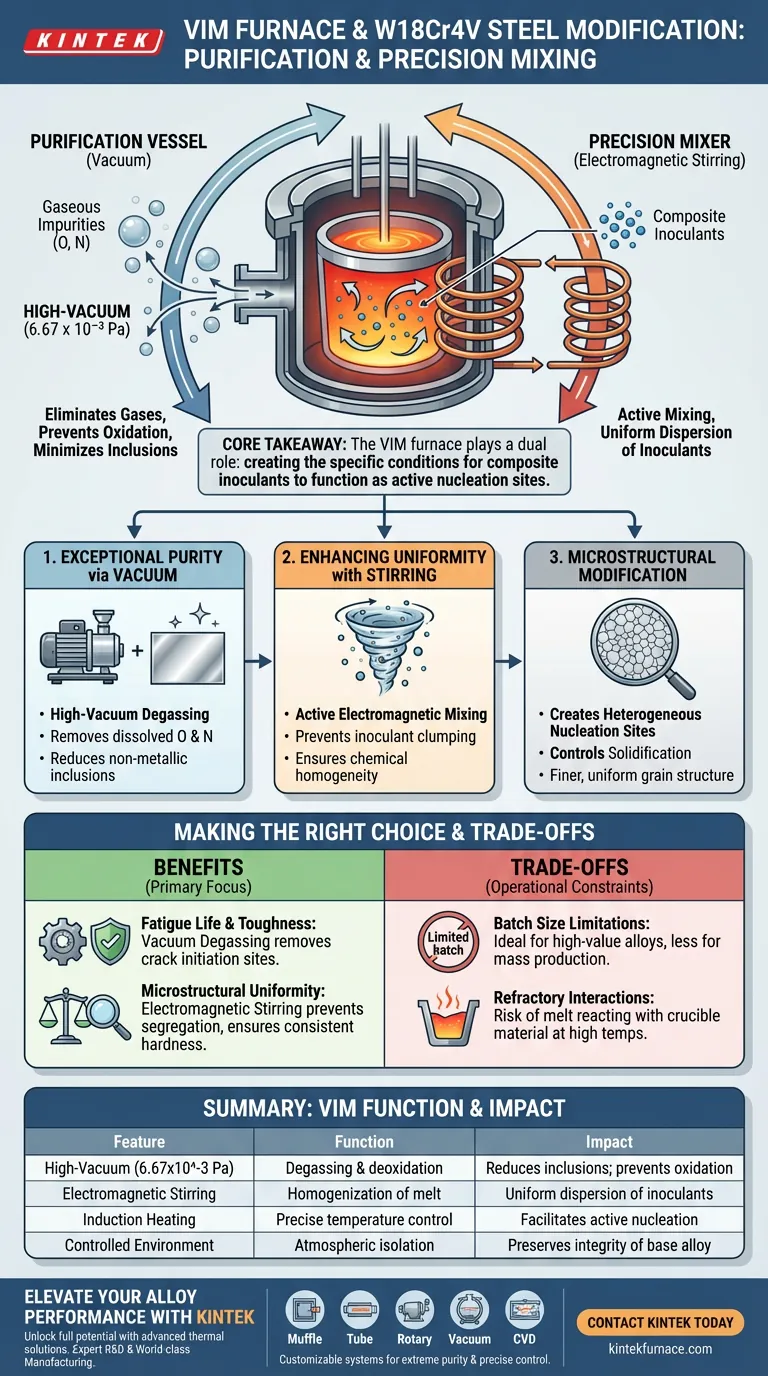

A vacuum induction melting (VIM) furnace functions as both a purification vessel and a precision mixer for W18Cr4V high-speed steel. It primarily serves to eliminate gaseous impurities through high-vacuum processing while utilizing electromagnetic forces to uniformly disperse composite inoculants, which is critical for modifying the steel's internal structure.

Core Takeaway The VIM furnace plays a dual role in steel modification: purification and homogenization. By combining a high-vacuum environment with electromagnetic stirring, it creates the specific conditions required for composite inoculants to function effectively, ensuring they become active nucleation sites rather than inactive inclusions.

Achieving Exceptional Purity via Vacuum

To modify W18Cr4V steel effectively, one must first eliminate variables that cause structural inconsistency. The VIM furnace establishes a baseline of extreme purity.

High-Vacuum Degassing

The furnace operates under a high vacuum, specifically around 6.67 x 10^-3 Pa. This low-pressure environment significantly lowers the partial pressure of gases in the chamber.

Elimination of Inclusions

By operating in this vacuum, the process actively draws out dissolved gases like oxygen and nitrogen from the liquid steel. This reduction is critical because it minimizes the formation of non-metallic inclusions (oxides and nitrides) that would otherwise weaken the steel.

Prevention of Oxidation

While melting, the vacuum prevents the molten steel from reacting with the atmosphere. This preserves the integrity of the base alloy and ensures the subsequent modification agents react with the steel, not the air.

Enhancing Uniformity with Induction Stirring

The physical mechanism of induction heating provides a secondary benefit that is arguably more important for modification than the heat itself: electromagnetic stirring.

Active Mixing of the Melt

The induction coils generate electromagnetic forces that cause the molten metal to circulate continuously. This is not passive melting; it is an active, dynamic process that ensures chemical homogeneity.

Dispersion of Composite Inoculants

For W18Cr4V steel, modification often involves adding "composite inoculants." Without stirring, these additives might float, sink, or clump together. The furnace's electromagnetic stirring forces these inoculants to diffuse rapidly and uniformly throughout the entire volume of liquid steel.

Facilitating Microstructural Modification

The ultimate goal of using a VIM furnace for this alloy is to control how the steel solidifies.

Creating Nucleation Sites

The uniform diffusion of inoculants mentioned above is not an end in itself; it is a means to control solidification. By spreading the inoculants evenly, the furnace ensures the distribution of heterogeneous nucleation sites.

Controlling Grain Structure

These nucleation sites are where crystals begin to form as the steel cools. An even distribution of sites leads to a finer, more uniform grain structure, which directly translates to the high performance expected of high-speed tool steels.

Understanding the Trade-offs

While VIM furnaces offer superior control for modification, it is important to recognize operational constraints to ensure realistic project planning.

Batch Size Limitations

VIM is inherently a batch process. Unlike continuous casting methods used for lower-grade steels, the output is limited to the crucible size. This makes it ideal for high-value alloys like W18Cr4V but less suitable for mass-production of structural steel.

Refractory Interactions

Despite the vacuum preventing atmospheric contamination, the molten steel is still in contact with the crucible (refractory lining). At high temperatures and low pressures, there is a risk of the melt reacting with the refractory material, potentially re-introducing trace impurities if the lining material is not carefully selected.

Making the Right Choice for Your Goal

When deciding if VIM is the correct processing route for your W18Cr4V modification, consider your specific performance targets.

- If your primary focus is Fatigue Life and Toughness: The VIM furnace is essential because its vacuum degassing capability removes the non-metallic inclusions that typically act as crack initiation sites.

- If your primary focus is Microstructural Uniformity: The VIM furnace is critical because its electromagnetic stirring ensures the modification agents (inoculants) are evenly dispersed, preventing segregation and ensuring consistent hardness.

The VIM furnace transforms W18Cr4V from a simple alloy mix into a high-performance material by creating the strictly controlled environment required for precise chemical modification.

Summary Table:

| Feature | Function in W18Cr4V Modification | Impact on Steel Quality |

|---|---|---|

| High-Vacuum (6.67 x 10^-3 Pa) | Degassing and deoxidation | Reduces inclusions; prevents oxidation of alloys |

| Electromagnetic Stirring | Homogenization of melt | Ensures uniform dispersion of composite inoculants |

| Induction Heating | Precise temperature control | Facilitates active nucleation and grain refinement |

| Controlled Environment | Atmospheric isolation | Preserves integrity of base alloy and modifiers |

Elevate Your Alloy Performance with KINTEK

Unlock the full potential of your high-speed steel with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, including specialized high-temperature lab furnaces customizable to your exact metallurgy needs. Whether you require extreme purity or precise microstructural control, our team is ready to design a system that fits your unique application.

Ready to optimize your modification process? Contact us today to speak with a specialist!

Visual Guide

References

- Lina Bai, Jie Liu. Effect of In Situ NbC-Cr7C3@graphene/Fe Nanocomposite Inoculant Modification and Refinement on the Microstructure and Properties of W18Cr4V High-Speed Steel. DOI: 10.3390/ma17050976

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does the introduction of bottom slits in a cold crucible affect melting performance? Boost Your ISM Efficiency

- What is the function of a high-temperature vacuum induction furnace in (Hf─Zr─Ti)C synthesis? Achieve 2100°C Precision

- What role does sustainability play in the IGBT induction melting furnace market? A Key Driver for Modern Foundries

- Can you heat graphite with induction? Unlock Rapid, High-Temperature Processing

- What are the advantages of using a vacuum induction melting furnace? Achieve Unmatched Purity and Control

- What are the advantages of vacuum induction furnace melting for superalloys? Achieve Purity and Performance

- What is the function of a vacuum induction furnace? Enhancing Purity in Silicon Steel Melting

- What is the primary purpose of preheating charge materials for C95800 aluminum bronze? Eliminate Porosity Defects