At its core, a vacuum induction melting (VIM) furnace provides unparalleled control over the entire metallurgical process. By combining rapid, clean induction heating with a highly controlled vacuum environment, these furnaces produce metals with exceptional purity, precise chemical compositions, and superior mechanical properties. This synergy directly translates into significant advantages in quality, efficiency, and material performance.

The primary advantage of a VIM furnace is not just melting metal quickly, but doing so in an environment that actively removes impurities. While induction provides the heat, the vacuum is what enables the production of ultra-clean, high-performance alloys that are impossible to achieve in an open atmosphere.

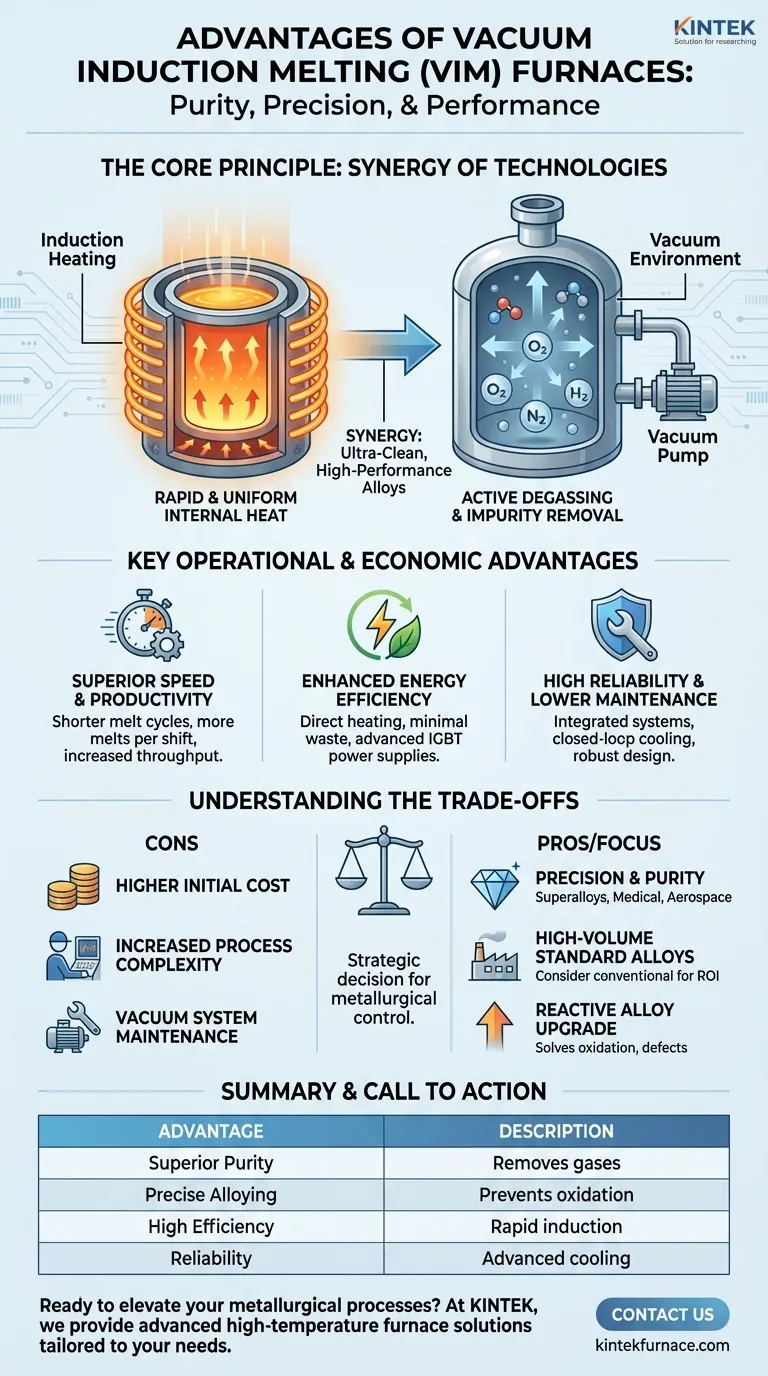

The Core Principle: How Vacuum and Induction Work Together

To understand the benefits, you must first understand the two core technologies at play. A VIM furnace is not just a heater; it is a sophisticated refining system where two processes work in tandem.

The Role of Induction Heating

Induction heating uses a powerful electromagnetic field to generate heat directly within the metal itself. This is fundamentally different from traditional furnaces that heat the outside of a crucible.

This internal heating method results in extremely rapid and uniform temperature distribution throughout the molten bath. It eliminates localized hot spots, reduces the risk of contamination from external heating elements, and ensures the entire melt reaches the target temperature simultaneously.

The Power of the Vacuum Environment

The vacuum system is the true differentiator. By removing the air and reducing the pressure inside the furnace chamber, it creates an environment where several critical refining actions can occur.

This process, known as degassing, pulls dissolved gases like oxygen, nitrogen, and hydrogen out of the molten metal. It also removes undesirable trace elements with high vapor pressures, effectively purifying the melt beyond what is possible with chemistry alone.

Precise Control Over Alloying

In a conventional furnace, reactive elements like titanium, aluminum, and rare earths can easily oxidize and be lost as slag. This makes hitting precise final compositions difficult and unpredictable.

The VIM furnace's oxygen-free environment prevents this loss. It allows metallurgists to make precise additions of these reactive elements, ensuring they are fully dissolved into the melt and contribute to the final alloy's desired properties.

Key Operational and Economic Advantages

The scientific principles of vacuum induction melting deliver tangible benefits in a production environment, impacting everything from speed and cost to final product quality.

Superior Speed and Productivity

The rapid heating rates inherent to induction technology lead to significantly shorter melt cycle times compared to other furnace types. This allows for more melts per shift, directly increasing factory throughput and overall productivity.

Enhanced Energy Efficiency

Because heat is generated directly in the material, very little energy is wasted heating the furnace chamber or the surrounding environment. Modern VIM systems utilize advanced power supplies, such as IGBT technology, which offer constant power output and minimal harmonic pollution, further optimizing energy consumption.

High Reliability and Lower Maintenance

VIM furnaces are designed as integrated, reliable systems. Many feature closed-loop cooling systems that use distilled water and heat exchangers. This design prevents the buildup of scale in cooling channels, a common cause of failure and downtime in lesser systems.

Furthermore, comprehensive electronic protection systems monitor for over-voltage, over-current, and water pressure issues, ensuring the equipment operates safely and reliably.

Understanding the Trade-offs

While powerful, VIM technology is not the universal solution for all melting operations. An objective assessment requires acknowledging its specific demands.

Higher Initial Capital Cost

The complexity of the system—including the robust vacuum chamber, high-capacity vacuum pumps, and sophisticated control instrumentation—results in a significantly higher initial investment compared to a standard air-melt induction or arc furnace.

Increased Process Complexity

Operating a VIM furnace effectively requires a higher level of operator skill and training. Managing vacuum levels, monitoring outgassing, and controlling the process sequence is more demanding than running a simple atmospheric melt.

Maintenance of Vacuum Systems

The vacuum components, including pumps, seals, valves, and gauges, require a dedicated and preventative maintenance schedule. This specialized upkeep is critical to ensuring the long-term performance and reliability of the furnace.

Making the Right Choice for Your Application

The decision to invest in a VIM furnace should be driven by the specific material requirements and business goals of your operation.

- If your primary focus is maximum purity and performance: VIM is the definitive choice for producing superalloys, medical-grade materials, aerospace components, and other critical parts where gas porosity or inclusions are unacceptable.

- If your primary focus is high-volume production of standard alloys: A conventional air-melt induction furnace may offer a more favorable return on investment if the extreme purity and compositional control of VIM is not required.

- If your primary focus is improving an existing process for reactive alloys: Upgrading to a VIM furnace is the most direct way to solve persistent problems with oxidation, gas defects, and inconsistent properties in alloys containing reactive elements.

Ultimately, investing in a VIM furnace is a strategic decision to control metallurgical outcomes with scientific precision.

Summary Table:

| Advantage | Description |

|---|---|

| Superior Purity | Removes dissolved gases and impurities via vacuum degassing for ultra-clean metals. |

| Precise Alloying | Prevents oxidation of reactive elements, enabling accurate chemical compositions. |

| High Efficiency | Rapid induction heating reduces cycle times and energy waste. |

| Reliability | Advanced cooling and protection systems minimize downtime and maintenance. |

Ready to elevate your metallurgical processes with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, medical, or other high-tech industries, our vacuum induction melting furnaces can help you achieve superior material performance. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys