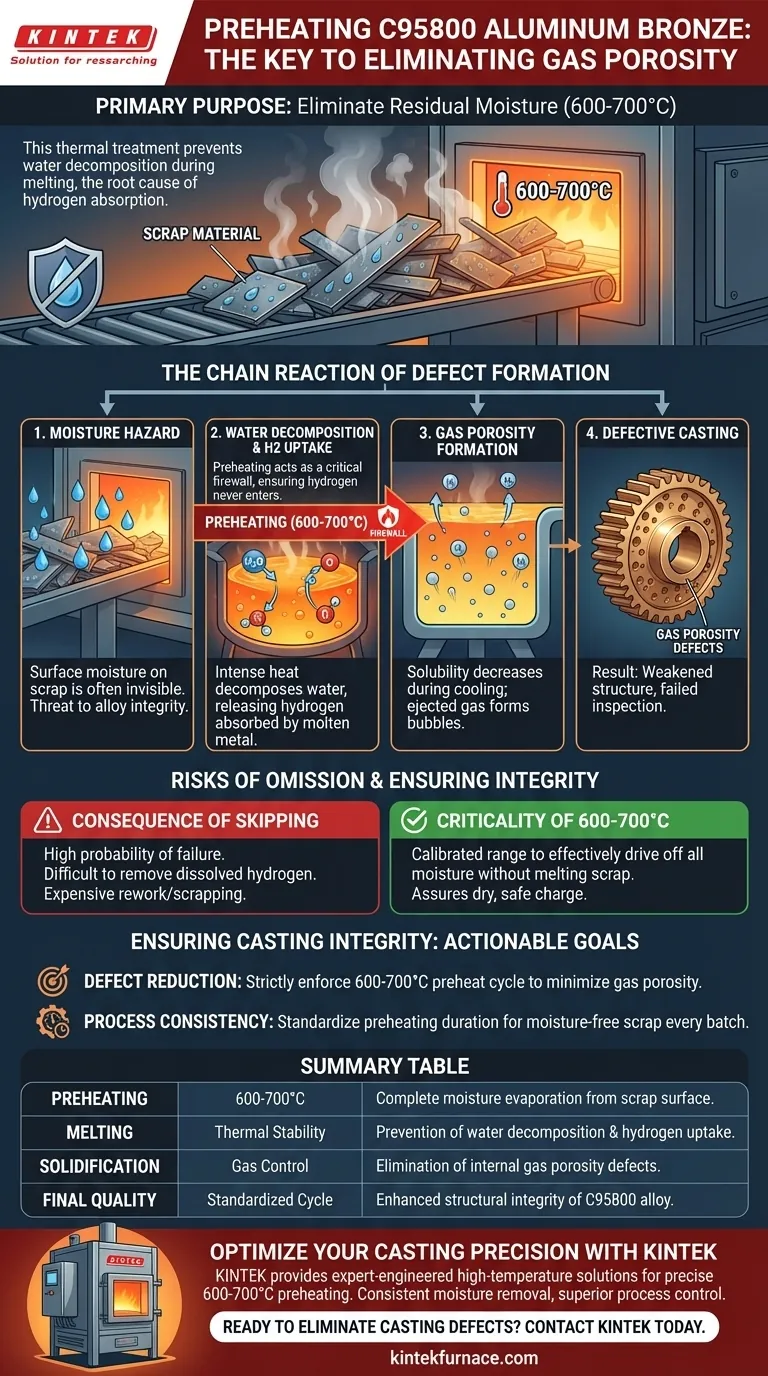

The primary purpose of preheating charge materials to 600-700°C is to completely eliminate residual moisture from the scrap surface. This thermal treatment prevents water from decomposing during the subsequent melting process, which is the root cause of hydrogen absorption in the melt. By removing the source of hydrogen, you significantly reduce the formation of gas porosity defects in the final C95800 aluminum bronze casting.

Eliminating moisture before the melt is a fundamental preventative measure. Preheating acts as a critical firewall, ensuring that hydrogen does not enter the molten metal to create structural weaknesses later.

The Chain Reaction of Defect Formation

The Moisture Hazard

Scrap materials used in casting often retain surface moisture that is not immediately visible.

If this moisture enters the furnace, it creates an immediate threat to the integrity of the alloy. Preheating to 600-700°C ensures that this moisture is fully evaporated before the metal reaches its melting point.

Water Decomposition and Hydrogen Uptake

When moisture is present during melting, the intense heat causes the decomposition of water.

This chemical breakdown releases hydrogen, which is readily absorbed by the molten aluminum bronze. Once absorbed, this hydrogen becomes trapped within the liquid metal.

The Formation of Gas Porosity

As the casting cools and solidifies, the solubility of hydrogen decreases, forcing the gas out of the solution.

This ejected gas forms bubbles, resulting in gas porosity defects. Preheating attacks this problem at the source, preventing the porosity by ensuring the hydrogen never enters the melt in the first place.

Understanding the Risks of Omission

The Consequence of Skipping Preheating

Omitting the preheating step might seem like a time-saver, but it introduces a high probability of failure.

Without this step, the melt is exposed to hydrogen sources that are difficult to remove once dissolved. This often leads to castings that fail inspection due to internal porosity, requiring expensive rework or scrapping of the part.

Criticality of the Temperature Range

The specific range of 600-700°C is not arbitrary.

It is calibrated to be sufficiently high to drive off all forms of moisture effectively without necessarily melting the scrap prematurely. Adhering to this specific window provides the highest assurance of a dry, safe charge.

Ensuring Casting Integrity

To apply this to your production process, consider the following specific goals:

- If your primary focus is Defect Reduction: strictly enforce the 600-700°C preheat cycle to minimize gas porosity at the source.

- If your primary focus is Process Consistency: Standardize the preheating duration to ensure every batch of scrap is completely free of residual moisture before charging.

By controlling moisture prior to melting, you secure the structural quality of the final aluminum bronze component.

Summary Table:

| Process Stage | Action/Temperature | Primary Benefit |

|---|---|---|

| Preheating | 600-700°C | Complete moisture evaporation from scrap surface |

| Melting | Thermal Stability | Prevention of water decomposition and hydrogen uptake |

| Solidification | Gas Control | Elimination of internal gas porosity defects |

| Final Quality | Standardized Cycle | Enhanced structural integrity of C95800 alloy |

Optimize Your Casting Precision with KINTEK

Don't let gas porosity compromise your alloy quality. KINTEK provides expert-engineered high-temperature solutions—including specialized Muffle, Tube, and Vacuum furnaces—designed to deliver the precise 600-700°C preheating environment your C95800 aluminum bronze requires.

Backed by industry-leading R&D and manufacturing, our customizable laboratory systems ensure consistent moisture removal and superior process control for metallurgy professionals.

Ready to eliminate casting defects? Contact KINTEK today to discuss your custom thermal needs.

Visual Guide

References

- Chawanan Thongyothee, Sombun Chareonvilisiri. The Effect of Gas Venting on the Mechanical Properties of C95800 Aluminum Bronze Castings. DOI: 10.48084/etasr.10993

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do IGBT induction melting furnaces improve precision in material production? Achieve Superior Metallurgical Control

- What types of metals and alloys are typically melted in induction-heated vacuum furnaces? Essential for High-Performance Materials

- What role does a vacuum arc melting furnace play in the melting of Fe60Co15Ni15Cr10 alloys? Unlock Superior Uniformity

- What are some common challenges faced when operating a vacuum casting furnace and their solutions? Overcome Melt Leaks and Vacuum Issues

- What is the function of a Vacuum Induction Heating Furnace in research? Synthesis and Purity of Copper-Bearing Steel

- Why are argon (Ar) and sulfur hexafluoride (SF6) introduced during magnesium alloy melting? Protect Your Melt Quality

- Why is a vacuum induction furnace used for the melting and casting of RAFM steel? Precision Purity for Nuclear Research

- What is the role of a Vacuum Induction Melting (VIM) furnace in Cobalt-Rhenium alloy production? Ensure Pure Alloys