Induction-heated vacuum furnaces are specifically designed for melting materials whose properties would be degraded by reacting with air. These primarily include superalloys, specialty stainless steels, and reactive metals such as titanium, zirconium, and molybdenum. The process is also critical for producing high-purity metals and complex alloys where precise chemical control is essential.

The defining characteristic of metals melted in a vacuum is their high reactivity with oxygen and nitrogen. A vacuum environment is not just a feature—it is a fundamental requirement to prevent the formation of impurities and achieve the exact chemical composition demanded by high-performance applications.

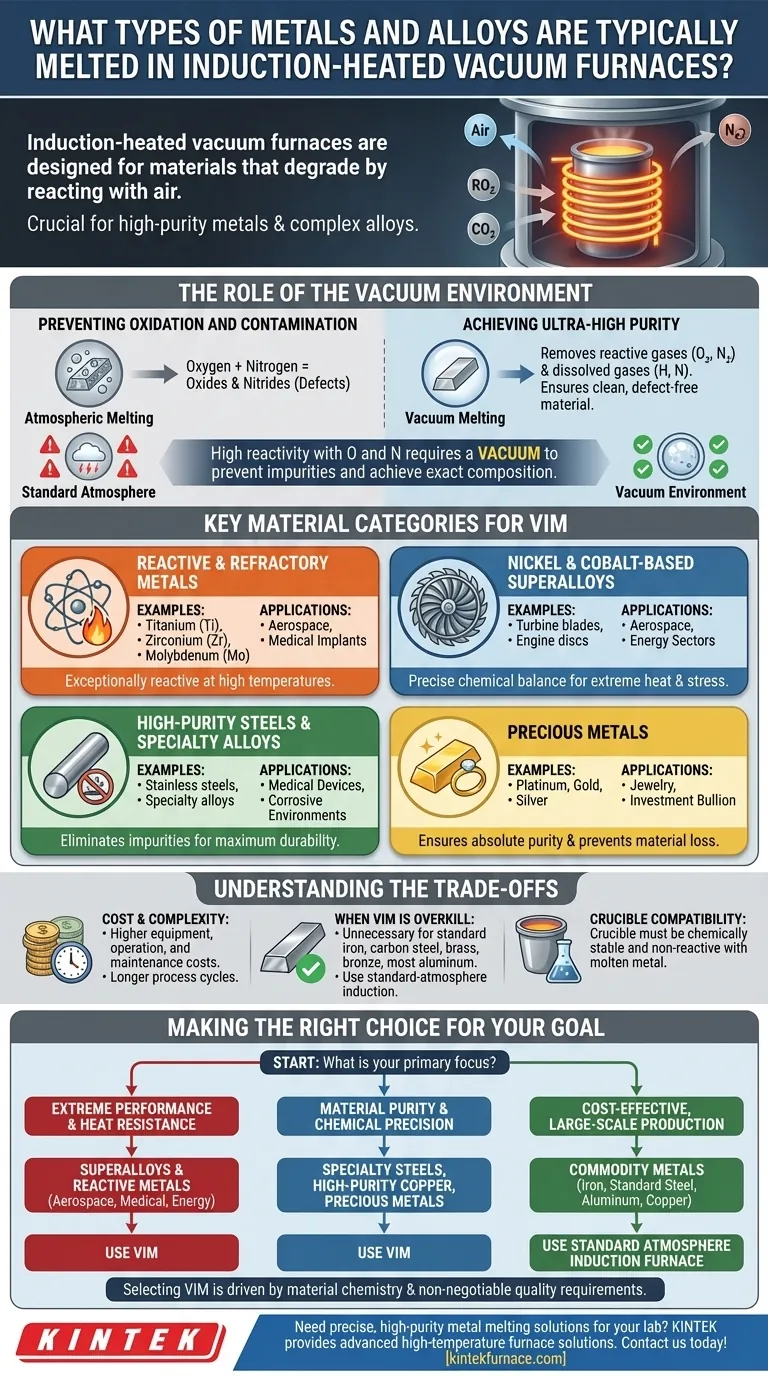

The Role of the Vacuum Environment

The decision to use a vacuum furnace is dictated by the chemical nature of the metal itself. For certain materials, melting in a standard atmosphere is not a viable option.

Preventing Oxidation and Contamination

Many advanced alloys contain elements like titanium, aluminum, and chromium, which have a high affinity for oxygen and nitrogen. When melted in the presence of air, these elements rapidly form oxides and nitrides.

These impurities act as defects in the final material, drastically reducing its strength, ductility, and fatigue life. A vacuum removes these reactive gases, ensuring the molten metal remains clean and free of contamination.

Achieving Ultra-High Purity

A vacuum environment also allows for the removal of dissolved gases, such as hydrogen and nitrogen, that are already present within the raw material. This process, known as vacuum degassing, is crucial for producing metals with the highest possible purity.

This level of cleanliness is essential for applications in the medical, aerospace, and electronics industries where material failure is not an option.

Key Material Categories for VIM

While many metals can be melted with induction, only specific categories justify the complexity and cost of a vacuum system.

Reactive and Refractory Metals

This group includes titanium (Ti), zirconium (Zr), and molybdenum (Mo). These metals are prized for their strength-to-weight ratio and corrosion resistance but are exceptionally reactive at high temperatures. Melting them in anything other than a high-vacuum or inert atmosphere is impossible without compromising their integrity.

Nickel and Cobalt-Based Superalloys

Superalloys are the backbone of the aerospace industry, used for turbine blades, engine discs, and other components operating under extreme heat and stress. Their performance relies on a precise and complex chemical balance of elements like nickel, cobalt, chromium, and aluminum.

Vacuum Induction Melting (VIM) is the standard for producing these alloys because it ensures this delicate chemistry is perfectly maintained.

High-Purity Steels and Specialty Alloys

While common steel is melted in air, certain high-performance stainless steels and specialty alloys require VIM. This process eliminates impurities that can become initiation points for corrosion or cracks, ensuring maximum durability for demanding applications.

Precious Metals

Metals like platinum, gold, and silver are often melted in vacuum induction furnaces. The vacuum ensures absolute purity, which is critical for investment-grade bullion and high-end jewelry. It also prevents any loss of this valuable material through oxidation.

Understanding the Trade-offs

Vacuum induction melting is a powerful tool, but it is not universally necessary or economical.

Cost and Complexity

Vacuum furnaces are significantly more expensive to purchase, operate, and maintain than their atmospheric counterparts. The process cycles are also longer due to the time required to pump down the chamber.

When VIM is Overkill

For the vast majority of common metals, VIM is unnecessary. Materials like standard iron, carbon steel, brass, bronze, and most aluminum alloys do not have the extreme reactivity that mandates a vacuum.

These materials are efficiently and economically melted in standard-atmosphere induction furnaces, where minor oxidation is acceptable or managed through other means.

Crucible Compatibility

The choice of crucible—the ceramic container that holds the molten metal—is critical. It must be chemically stable and not react with the highly reactive molten metal. This adds another layer of technical consideration, particularly when melting materials like titanium.

Making the Right Choice for Your Goal

The decision to use vacuum induction melting should be based entirely on the material requirements and the performance demands of the end product.

- If your primary focus is extreme performance and heat resistance: VIM is the correct choice for superalloys and reactive metals intended for aerospace, medical, or energy applications.

- If your primary focus is material purity and chemical precision: Use VIM for specialty steels, high-purity copper, or precious metals where even trace impurities are unacceptable.

- If your primary focus is cost-effective, large-scale production: A standard-atmosphere induction furnace is the appropriate tool for commodity metals like iron, standard steels, and most aluminum or copper alloys.

Ultimately, selecting vacuum induction melting is a decision driven by the material's inherent chemistry and the non-negotiable quality requirements of its final application.

Summary Table:

| Material Category | Examples | Key Applications |

|---|---|---|

| Reactive and Refractory Metals | Titanium, Zirconium, Molybdenum | Aerospace, medical implants |

| Nickel and Cobalt-Based Superalloys | Turbine blades, engine discs | Aerospace, energy sectors |

| High-Purity Steels and Specialty Alloys | Stainless steels, specialty alloys | Medical devices, corrosive environments |

| Precious Metals | Platinum, Gold, Silver | Jewelry, investment bullion |

Need precise, high-purity metal melting solutions for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements. Contact us today to discuss how our expertise can enhance your material processing and achieve superior results!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications