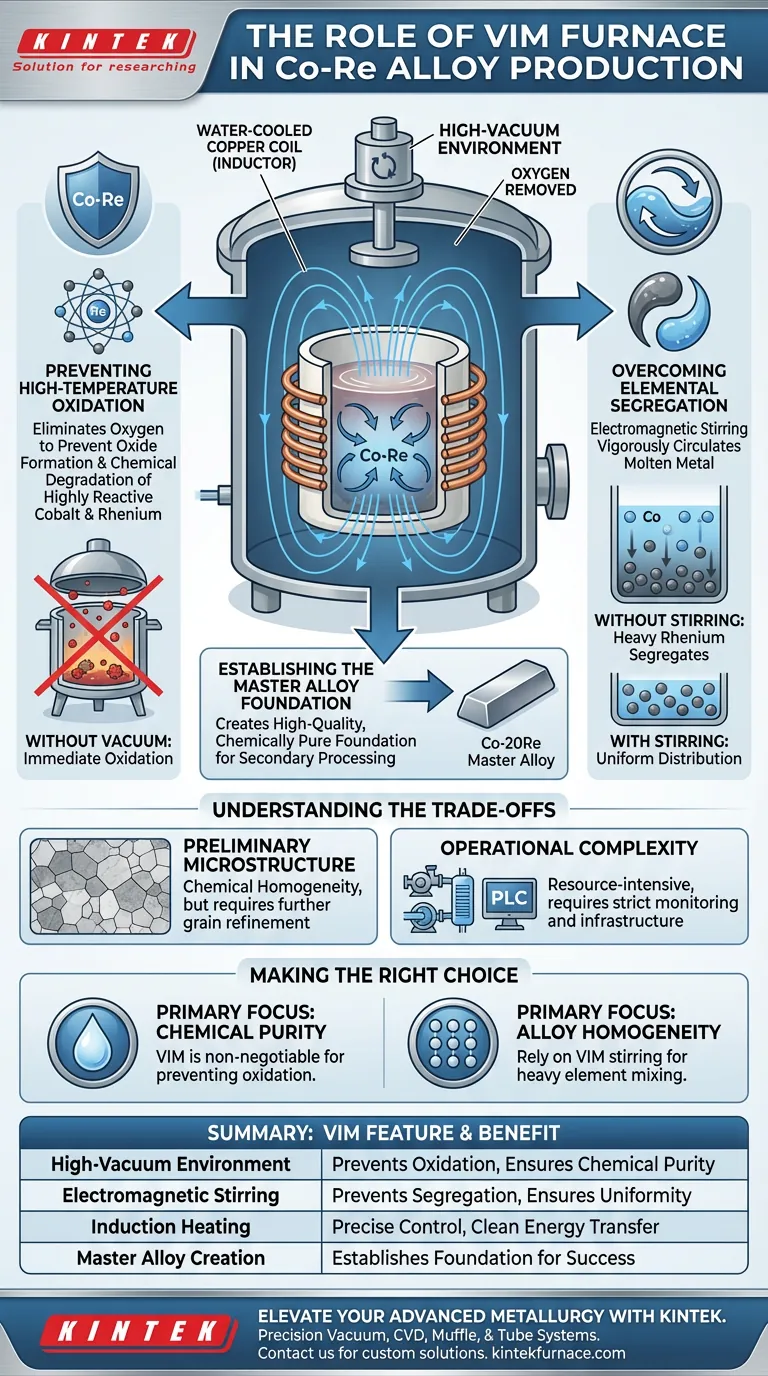

The Vacuum Induction Melting (VIM) furnace serves as the critical foundational step in the manufacturing of Cobalt-Rhenium (Co-Re) alloys. Its primary role is to provide a high-vacuum environment that completely prevents the oxidation of highly reactive Cobalt and Rhenium, while simultaneously utilizing electromagnetic forces to ensure these elements mix uniformly.

The VIM furnace acts as a dual-purpose purification and homogenization tool; it eliminates atmospheric contamination to preserve chemical purity and actively stirs elements of vastly different atomic masses to prevent segregation.

The Critical Functions for Co-Re Alloys

Preventing High-Temperature Oxidation

Cobalt and Rhenium are highly reactive elements, particularly when subjected to the intense heat required for melting.

Without protection, these metals would react immediately with oxygen in the atmosphere, forming oxides that degrade the material's structural integrity.

The VIM furnace mitigates this by operating under a high-vacuum environment, effectively removing oxygen and creating a neutral space where the alloy can melt without chemical degradation.

Overcoming Elemental Segregation

One of the distinct challenges in Co-Re production is the physical nature of Rhenium, which is a high-mass solute element.

Because Rhenium is significantly heavier than Cobalt, it naturally tends to sink or segregate from the matrix during melting.

The VIM furnace addresses this through electromagnetic stirring, a natural byproduct of the induction heating process that vigorously circulates the molten metal to ensure a uniform distribution of Rhenium.

Establishing the Master Alloy Foundation

The VIM process is typically used to prepare the "master alloy," specifically noted as Co-20Re in high-performance applications.

This step does not necessarily produce the final component but establishes a high-quality foundation free of impurities.

By securing the chemical composition at this stage, manufacturers ensure success in subsequent secondary melting processes.

Operational Mechanics

The Induction Heating Principle

The furnace utilizes a water-cooled copper coil (the inductor) powered by a medium-frequency power supply.

This generates a rapidly changing electromagnetic field that penetrates the metal charge, inducing electrical currents that generate heat directly within the material.

Precise Environmental Control

Beyond the vacuum, VIM furnaces often feature gas flow control systems to introduce inert gases like argon or helium.

This allows for precise control over volatile impurities and further protects the melt during specific stages of the alloying process.

Understanding the Trade-offs

Preliminary vs. Final Microstructure

While VIM excels at chemical homogenization, it provides what is described as a "preliminary" uniform distribution.

It establishes the correct chemistry, but it may not produce the refined grain structure required for the final application, necessitating secondary processing (such as remelting).

Operational Complexity

VIM furnaces are complex systems requiring robust support infrastructure, including vacuum pumps, cooling systems for the furnace body, and emergency shutdown mechanisms.

Strict monitoring via PLCs (Programmable Logic Controllers) is required to maintain the delicate balance of temperature and pressure, making the process resource-intensive.

Making the Right Choice for Your Goal

When evaluating the role of VIM in your production line, consider your specific metallurgical requirements:

- If your primary focus is Chemical Purity: The VIM furnace is non-negotiable for preventing the oxidation of reactive elements like Cobalt and Rhenium.

- If your primary focus is Alloy Homogeneity: You must rely on the electromagnetic stirring of VIM to mix heavy elements (Rhenium) that would otherwise segregate in a static melt.

The VIM furnace is not merely a heating vessel; it is the primary mechanism for stabilizing the chemistry of complex, high-performance alloys before they undergo final processing.

Summary Table:

| Feature | Function in Co-Re Production | Benefit |

|---|---|---|

| High-Vacuum Environment | Eliminates oxygen and atmospheric gases | Prevents oxidation and chemical degradation |

| Electromagnetic Stirring | Vigorously circulates molten metal | Ensures uniform Rhenium distribution and prevents segregation |

| Induction Heating | Direct internal heating via magnetic field | Precise temperature control and clean energy transfer |

| Master Alloy Creation | Establishes the Co-20Re foundation | Secures chemical purity for secondary processing stages |

Elevate Your Advanced Metallurgy with KINTEK

Precision in Cobalt-Rhenium alloying starts with a superior thermal environment. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Vacuum, CVD, Muffle, and Tube systems tailored to your laboratory's most demanding specifications.

Whether you require a customizable vacuum furnace for master alloy production or a specialized system for material research, our engineering team ensures your furnace meets the exact purity and homogenization standards your work deserves.

Ready to optimize your high-temperature processes? Contact our experts today and let us design your ideal solution!

Visual Guide

References

- Torben Fiedler, Joachim Rösler. Temperature-Dependent Young’s Modulus of TaC- and TiC-Strengthened Co-Re-Based Alloys. DOI: 10.3390/met14030324

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the function of a vacuum induction furnace with cold copper crucible in Ti-5Al-2.5Sn alloy preparation?

- What are the benefits of precise temperature control in channel induction furnaces? Achieve Superior Metallurgical Quality and Efficiency

- What are the maintenance benefits of using IGBT technology in induction melting? Maximize Uptime & Reduce Downtime

- What experimental environment does a vacuum induction furnace provide for HRB400? Ensure Ultra-Purity Steel Research

- What is the role of a vacuum induction melting furnace in Ti50Ni47Fe3 alloys? Achieve High Purity and Homogeneity

- How does induction heating compare to resistance furnaces in ammonia decomposition? Experience Dynamic Precision Control

- How does a Vacuum Induction Furnace function in Silicon-Manganese deoxidation simulation? Achieve High-Purity Results

- What is the role of vacuum induction furnaces in aluminum alloy oxidation research? Mastering Melt Environment Control