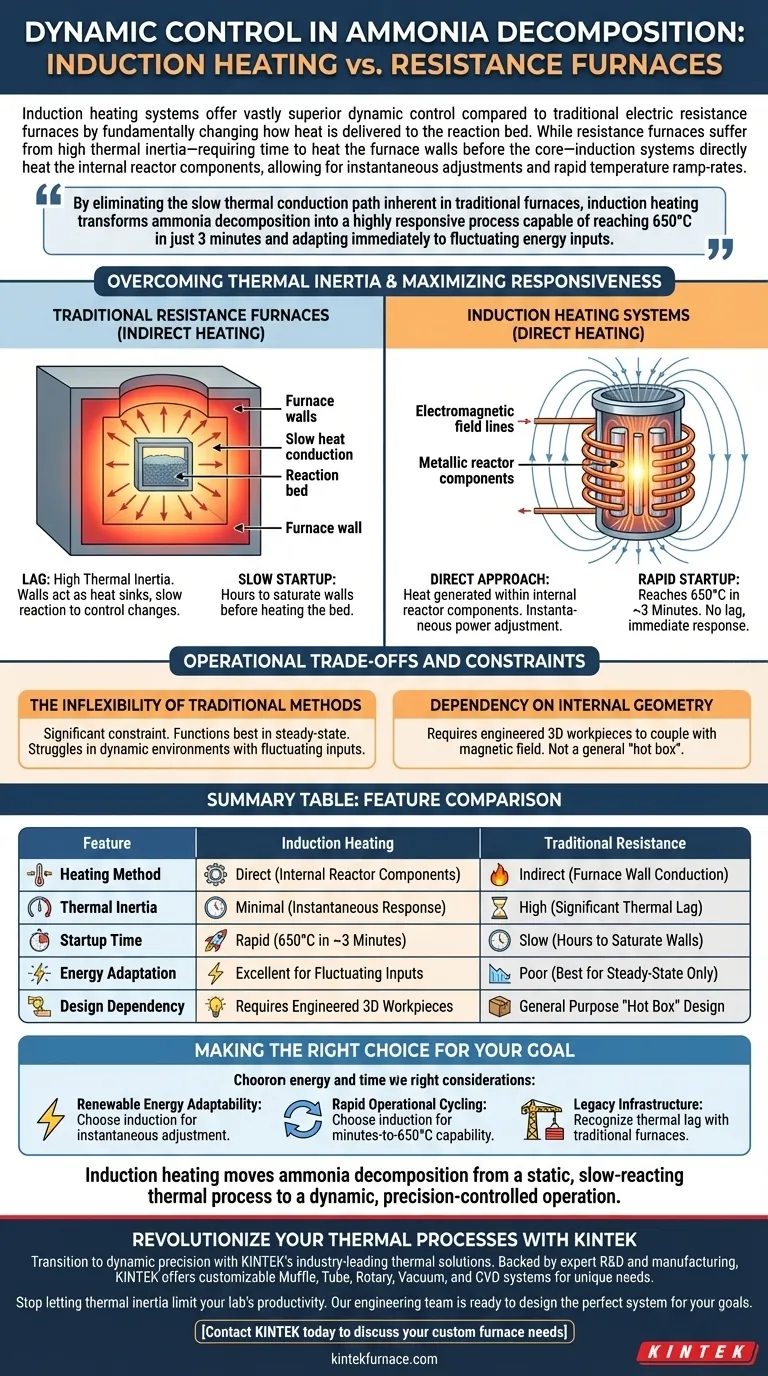

Induction heating systems offer vastly superior dynamic control compared to traditional electric resistance furnaces by fundamentally changing how heat is delivered to the reaction bed. While resistance furnaces suffer from high thermal inertia—requiring time to heat the furnace walls before the core—induction systems directly heat the internal reactor components, allowing for instantaneous adjustments and rapid temperature ramp-rates.

By eliminating the slow thermal conduction path inherent in traditional furnaces, induction heating transforms ammonia decomposition into a highly responsive process capable of reaching 650°C in just 3 minutes and adapting immediately to fluctuating energy inputs.

Overcoming Thermal Inertia

The Lag of Resistance Furnaces

Traditional electric resistance furnaces operate on an indirect heating principle. The system must first heat the massive furnace walls, which then slowly transfer heat to the reaction bed via conduction.

This process creates high thermal inertia. The furnace walls act as a heat sink, preventing the system from reacting quickly to changes in control settings.

The Direct Approach of Induction

In contrast, induction heating systems bypass the furnace structure entirely. They generate heat directly within the internal reactor components (the 3D workpieces).

This eliminates the need to heat the containment vessel first. By removing the slow thermal conduction path, energy is delivered exactly where it is needed without delay.

Speed and Responsiveness

Rapid Startup Capabilities

The most tangible benefit of direct heating is the dramatic reduction in startup time. Because the system does not need to saturate the furnace walls with heat, it reaches operating temperature quickly.

Specifically, an induction system can ramp from room temperature to 650°C in approximately 3 minutes.

Instantaneous Power Adjustment

Control in an induction system is virtually instantaneous. Because the heat is generated inside the workpiece, the thermal output is directly locked to the power input.

When the power input changes, the heat generation changes immediately. There is no lag time while waiting for heating elements or walls to cool down or warm up.

Operational Trade-offs and Constraints

The Inflexibility of Traditional Methods

The high thermal inertia of resistance furnaces acts as a significant operational constraint. They function best in steady-state operations where variables rarely change.

They struggle significantly in dynamic environments. If energy input drops or process requirements shift, the system responds too slowly to maintain optimal conditions.

Dependency on Internal Geometry

Induction systems rely on specific internal reactor components to function. The efficiency cited—such as the 3-minute startup—is dependent on these 3D workpieces being designed to couple effectively with the magnetic field.

Unlike a resistance furnace which acts as a general "hot box," induction requires an engineered approach to the internal reaction bed to achieve these results.

Making the Right Choice for Your Goal

To select the correct heating methodology for your ammonia decomposition application, consider your operational constraints:

- If your primary focus is adaptability to renewable energy: Choose induction heating, as its ability to instantaneously adjust to power input allows you to handle fluctuating energy sources effectively.

- If your primary focus is rapid operational cycling: Choose induction heating to leverage the capability of reaching 650°C in minutes rather than hours.

- If your primary focus is utilizing legacy infrastructure: Recognize that traditional resistance furnaces will limit your ability to react to process changes due to their inherent thermal lag.

Induction heating moves ammonia decomposition from a static, slow-reacting thermal process to a dynamic, precision-controlled operation.

Summary Table:

| Feature | Induction Heating Systems | Traditional Resistance Furnaces |

|---|---|---|

| Heating Method | Direct (Internal Reactor Components) | Indirect (Furnace Wall Conduction) |

| Thermal Inertia | Minimal (Instantaneous Response) | High (Significant Thermal Lag) |

| Startup Time | Rapid (650°C in ~3 Minutes) | Slow (Hours to Saturate Walls) |

| Energy Adaptation | Excellent for Fluctuating Inputs | Poor (Best for Steady-State Only) |

| Design Dependency | Requires Engineered 3D Workpieces | General Purpose "Hot Box" Design |

Revolutionize Your Thermal Processes with KINTEK

Transition from static heating to dynamic precision with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces—all fully customizable to meet your unique ammonia decomposition and material science requirements.

Stop letting thermal inertia limit your lab's productivity. Whether you need rapid operational cycling or adaptability to renewable energy sources, our engineering team is ready to design the perfect system for your goals.

Contact KINTEK today to discuss your custom furnace needs

Visual Guide

References

- Débora de Figueiredo Luiz, Jurriaan Boon. Use of a 3D Workpiece to Inductively Heat an Ammonia Cracking Reactor. DOI: 10.3390/suschem6040043

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is a vacuum environment necessary for PBF-EB? Ensure Beam Precision & Material Purity

- What is the function of the induction heating furnace and vacuum pump system during AlN crystal preparation?

- What is the function of a vacuum induction furnace? Achieve Homogeneity in Fe-C-B-Cr-W Alloys

- What type of heating system is commonly used in vacuum casting furnaces and how does it work? Discover Induction Heating for Pure, Efficient Melting

- What are the advantages and uses of induction furnaces in foundries? Achieve Fast, Clean, and Precise Metal Melting

- How do IGBT induction melting furnaces compare to traditional melting systems? A Generational Leap in Melting Technology

- How do induction furnaces contribute to cost savings in the long term? Unlock Long-Term Efficiency and ROI

- How does electromagnetic induction contribute to the heating process in an induction melting furnace? Achieve Superior Metal Melting Efficiency