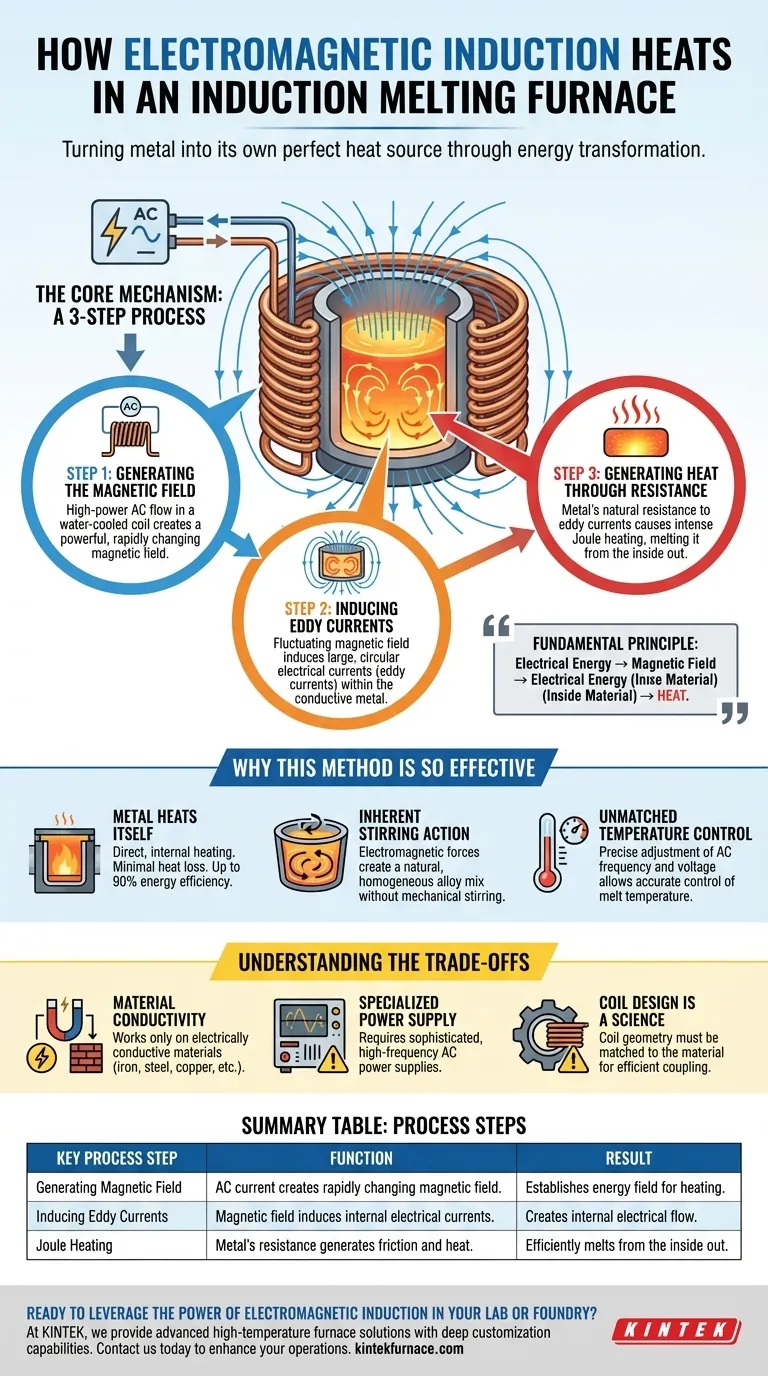

At its core, an induction melting furnace uses electromagnetic induction to turn the metal being melted into its own heat source. An alternating current (AC) in a copper coil generates a powerful, rapidly changing magnetic field, which in turn creates large electrical currents, known as eddy currents, directly within the conductive metal. The metal’s natural resistance to these currents generates intense heat, causing it to melt from the inside out.

The fundamental principle is transformation: electrical energy is converted into a magnetic field, which is then converted back into electrical energy inside the target material, where it finally becomes heat. This direct, non-contact heating method is what makes induction furnaces exceptionally efficient and controllable.

The Core Mechanism of Induction Heating

To understand the process, it's best to break it down into three distinct physical steps. Each step is a conversion of energy from one form to another.

Step 1: Generating the Magnetic Field

An induction furnace begins with a high-power AC supply connected to a large, water-cooled copper coil. This coil is typically wrapped around a crucible containing the metal charge.

When AC flows through this coil, it generates a powerful and dynamic magnetic field that constantly and rapidly changes its polarity and intensity. The design of the coil is critical for concentrating this magnetic field within the target material.

Step 2: Inducing Eddy Currents

This fluctuating magnetic field penetrates the electrically conductive metal inside the crucible. According to Faraday's Law of Induction, a changing magnetic field will induce an electrical current in any conductor placed within it.

These induced currents are called eddy currents. They are circular loops of electrical current that form entirely within the mass of the metal, mirroring the shape of the external coil.

Step 3: Generating Heat Through Resistance

All conductive materials have some level of electrical resistance. As the large eddy currents are forced to flow through the metal, they encounter this resistance.

This opposition to the flow of electricity generates immense friction at a molecular level, a phenomenon known as Joule heating. This friction is converted directly into thermal energy, rapidly raising the metal's temperature past its melting point.

Why This Method is So Effective

The elegance of induction heating lies not just in its ability to generate heat, but in the unique characteristics of the process. This separates it from traditional fuel-fired or arc furnaces.

The Metal Heats Itself

Unlike conventional furnaces that heat a chamber and rely on radiation or convection to transfer heat to the material, an induction furnace heats the material directly. The furnace components, like the crucible and coil, remain relatively cool. This minimizes heat loss and dramatically increases energy efficiency, often reaching up to 90%.

Inherent Stirring Action

The powerful magnetic fields and eddy currents create a natural stirring effect within the molten metal. This electromagnetic stirring ensures a more homogeneous and consistent alloy mix without the need for mechanical equipment, improving the final quality of the cast material.

Unmatched Temperature Control

The amount of heat generated is directly proportional to the power supplied to the coil. By precisely adjusting the frequency and voltage of the AC power supply, operators can control the temperature of the melt with incredible accuracy. This prevents overheating and the loss of valuable alloying elements.

Understanding the Trade-offs

While powerful, the induction method has specific requirements and limitations that are critical to understand for proper application.

The Primary Limitation: Material Conductivity

Induction heating works only on electrically conductive materials. Metals like iron, steel, copper, and aluminum are ideal. Non-conductive materials like ceramics or plastics cannot be heated directly by this method. To melt them, a conductive crucible (like graphite) must be used, which is then heated by induction and transfers its heat to the non-conductive material inside.

The Need for a Specialized Power Supply

Induction furnaces cannot simply be plugged into a standard wall outlet. They require sophisticated, high-power supplies that can deliver precisely controlled high-frequency alternating current. This equipment represents a significant part of the furnace's cost and complexity.

Coil Design is a Science

The efficiency of the entire system depends heavily on the geometry of the induction coil. The coil must be carefully designed and matched to the size, shape, and type of material being melted to ensure the magnetic field is coupled effectively. An improperly designed coil will waste energy and result in poor performance.

Making the Right Choice for Your Goal

Understanding the principles of induction heating allows you to leverage its benefits for specific operational goals.

- If your primary focus is process efficiency: The direct, internal heating mechanism of induction offers the highest possible energy conversion rate, drastically reducing wasted energy compared to fuel-fired furnaces.

- If your primary focus is material quality: The electromagnetic stirring and precise temperature control ensure a highly homogeneous melt and prevent the loss of critical alloy elements.

- If your primary focus is workplace safety and environmental impact: Induction is a clean process with no combustion byproducts, leading to better air quality and a significant reduction in carbon emissions.

By turning the material into its own perfect heat source, electromagnetic induction provides a level of control and efficiency that other heating technologies cannot match.

Summary Table:

| Key Process Step | Function | Result |

|---|---|---|

| Generating Magnetic Field | AC current in a copper coil creates a rapidly changing magnetic field. | Establishes the energy field for heating. |

| Inducing Eddy Currents | The magnetic field induces circular electrical currents (eddy currents) inside the conductive metal. | Creates internal electrical flow within the material itself. |

| Joule Heating | The metal's resistance to the eddy currents generates intense friction and heat. | Efficiently melts the metal from the inside out. |

Ready to leverage the power of electromagnetic induction in your lab or foundry?

At KINTEK, we harness our exceptional R&D and in-house manufacturing capabilities to provide advanced high-temperature furnace solutions. Our product line, including Induction Melting Furnaces, Muffle Furnaces, Tube Furnaces, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Whether your focus is on process efficiency, material quality, or workplace safety, our team can design a system that turns your conductive materials into their own perfect heat source. Contact us today to discuss how our induction heating technology can enhance your operations.

Get in touch with our experts to find your solution

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys