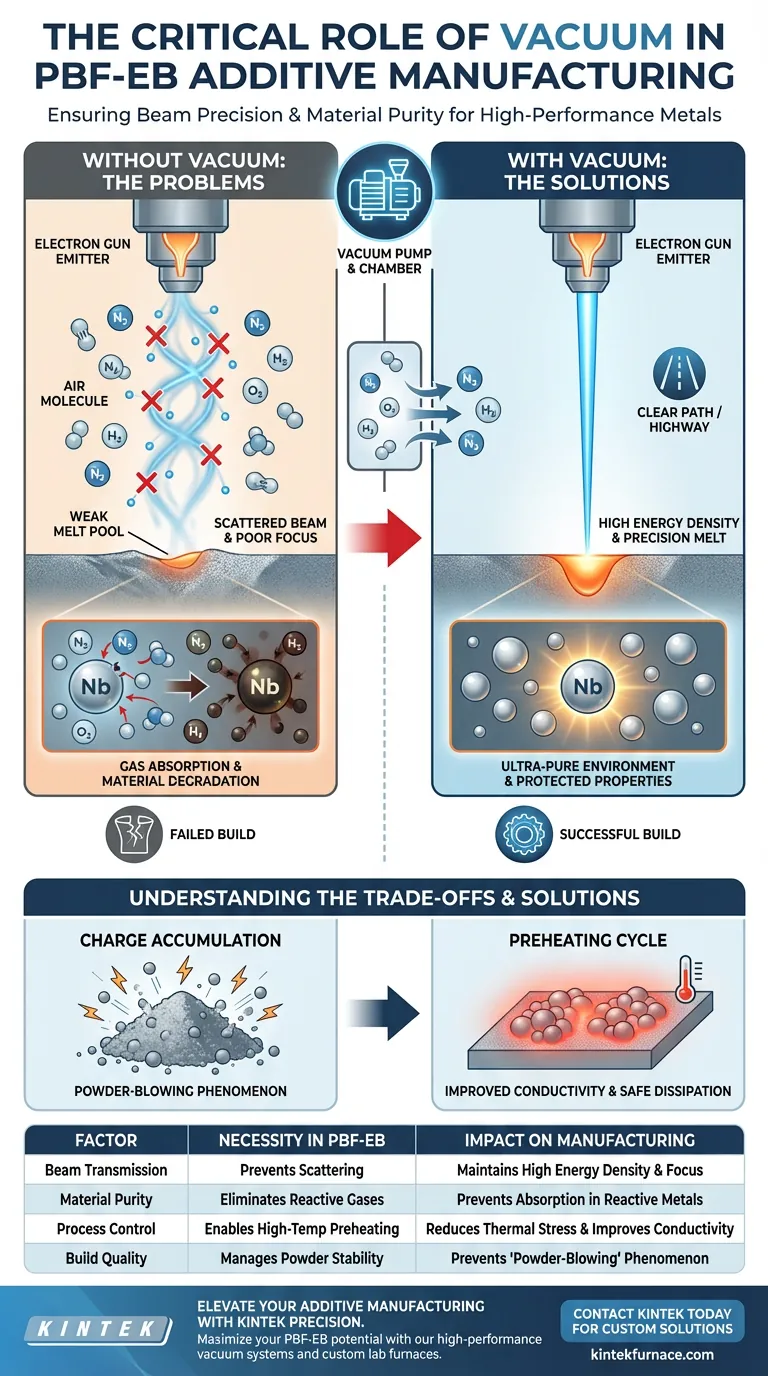

A vacuum environment is strictly mandatory in Electron Beam Powder Bed Fusion (PBF-EB) to ensure the fundamental physics of the energy source function correctly. Without this vacuum, air molecules would obstruct the electron path, causing the beam to scatter and lose focus, while simultaneously contaminating the purity of the metal being processed.

The Core Insight The PBF-EB vacuum serves a dual role: it acts as a clear "highway" for the electron beam to travel without collision, and it functions as a shield, creating an ultra-pure environment that prevents reactive metals from absorbing gases and degrading during the melt.

The Physics of Beam Transmission

Preventing Electron Scattering

The primary mechanical reason for the vacuum is to maintain the integrity of the energy source. Electrons have mass, and as they travel from the emitter to the powder bed, they are highly susceptible to collisions.

If air molecules were present in the chamber, they would physically deflect the electrons. This scattering effect would diffuse the beam, making it impossible to focus enough energy to melt the metal powder effectively.

Ensuring Energy Density

By removing air molecules, the vacuum ensures a clear path for the electrons. This allows the system to maintain a highly focused energy beam.

This focus is critical for achieving the precise melt pool dimensions required for high-resolution additive manufacturing.

Material Integrity and Environmental Purity

Protecting Reactive Materials

Beyond beam physics, the vacuum provides an essential chemical benefit: extreme environmental purity. Many high-performance metals used in PBF-EB are highly reactive at elevated temperatures.

The primary reference highlights niobium and other superconducting materials as prime examples. These materials are incredibly sensitive to their environment.

Preventing Gas Absorption

In a standard atmosphere, or even a low-quality inert atmosphere, hot metals can absorb oxygen, nitrogen, or hydrogen. This absorption fundamentally alters the material properties.

For superconducting components, this deterioration is catastrophic. The vacuum environment prevents these gases from being absorbed, ensuring the final component retains the high performance characteristics required for specialized applications.

Understanding the Trade-offs

The Challenge of Charge Accumulation

While the vacuum enables the beam to travel, it also creates an electrical challenge. Because there is no atmosphere to help dissipate charge, electrons hitting the powder can cause charge accumulation.

If this charge builds up, it causes the "powder-blowing phenomenon," where the powder particles repel each other and scatter, ruining the build.

The Necessity of Preheating

To counteract the effects of the vacuum on the powder's electrical state, the process requires a high-power rapid scanning preheating cycle.

As noted in the supplementary data, this step partially sinters the powder before the main melt. This improves electrical conductivity, allowing the charge to dissipate safely and preventing thermal defects like cracking.

Making the Right Choice for Your Goal

The necessity of the vacuum defines the strengths and operational requirements of PBF-EB technology.

- If your primary focus is processing superconductors (like Niobium): The vacuum is your critical asset, offering the purity required to prevent gas absorption and maintain material performance.

- If your primary focus is beam precision: The vacuum is the enabling factor that prevents scattering, ensuring the energy density needed for successful fusion.

The vacuum is not just an empty space; it is a meticulously controlled tool that enables the processing of the world's most sensitive and high-performance metals.

Summary Table:

| Factor | Necessity in PBF-EB | Impact on Manufacturing |

|---|---|---|

| Beam Transmission | Prevents electron scattering | Maintains high energy density and focus |

| Material Purity | Eliminates reactive gases | Prevents absorption in metals like Niobium |

| Process Control | Enables high-temp preheating | Reduces thermal stress and improves conductivity |

| Build Quality | Manages powder stability | Prevents the 'powder-blowing' phenomenon |

Elevate Your Additive Manufacturing with KINTEK Precision

Maximize the potential of your PBF-EB processes with specialized thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum systems and customizable lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—tailored to the unique needs of researchers and industrial manufacturers. Whether you are processing reactive superconductors or optimizing beam precision, our equipment ensures the ultra-pure environment your materials demand.

Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Tobia Romano, Maurizio Vedani. Metal additive manufacturing for particle accelerator applications. DOI: 10.1103/physrevaccelbeams.27.054801

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the primary role of a vacuum induction furnace for TWIP steel? Ensure Purity and Chemical Precision

- What role does a crucible lid play during the vacuum induction smelting of AlV55 alloys? Boost Purity & Yield

- What are the main advantages of using a VIM furnace? Achieve High-Purity Metals with Precision Control

- What are the key applications of IGBT induction melting furnaces? Unlock Precision & Purity in Metal Melting

- What is a Vacuum Induction Melting (VIM) furnace and what does it do? Discover Precision Melting for High-Purity Alloys

- What is the role of a vacuum arc furnace in TixNbMoTaW RHEA synthesis? Key steps for refractory alloy prep

- What are the control advantages of induction heating? Achieve Precision, Speed, and Efficiency

- What types of metals and alloys are typically melted in induction-heated vacuum furnaces? Essential for High-Performance Materials