The primary role of a vacuum induction furnace (VIF) in the melting process of high-strength TWIP (Twinning Induced Plasticity) steel is to guarantee precise chemical composition by isolating the melt from atmospheric contamination. Specifically, it provides a controlled vacuum or inert gas environment to prevent the oxidative loss of active alloying elements, most notably manganese, while utilizing electromagnetic forces to ensure a homogenous mixture.

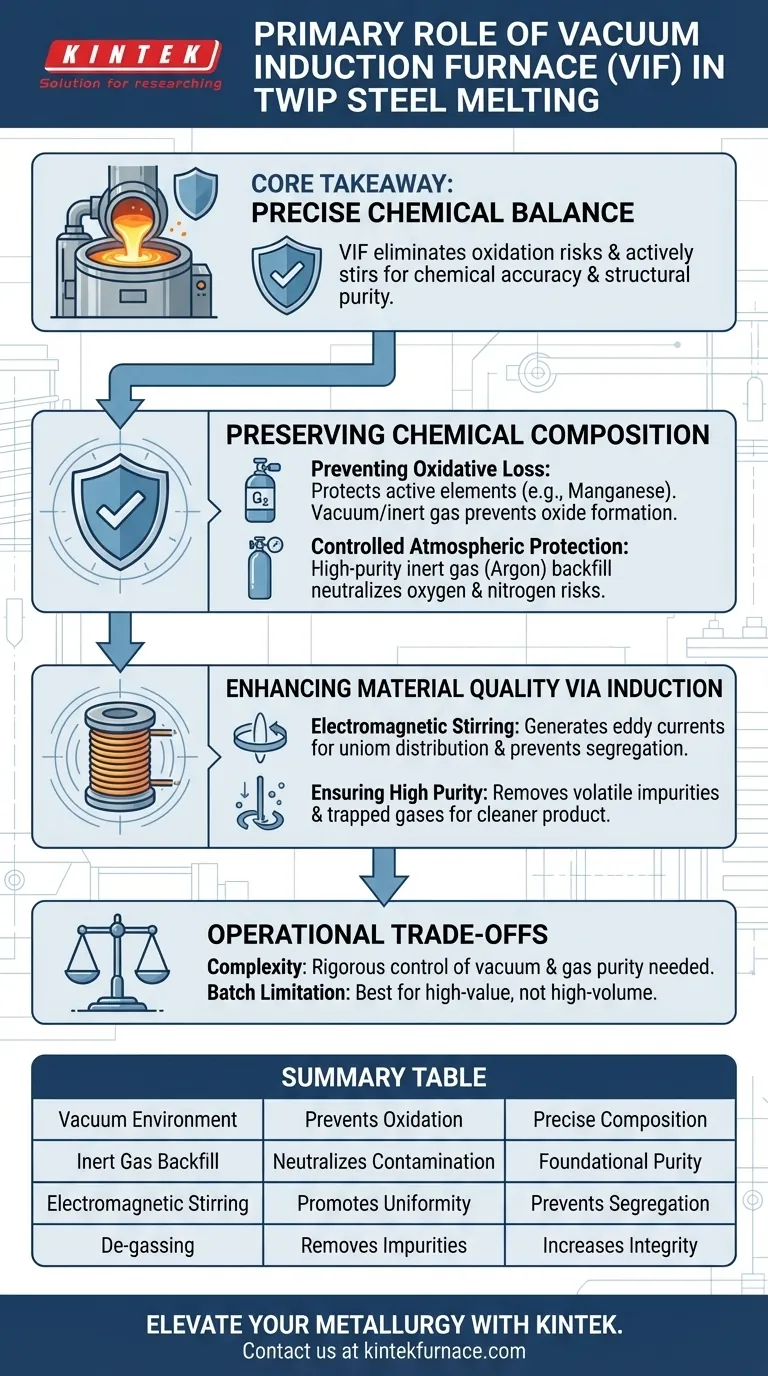

Core Takeaway Achieving the specific mechanical properties of TWIP steel requires maintaining an exact chemical balance that is easily disrupted by oxygen. The vacuum induction furnace solves this by eliminating oxidation risks and actively stirring the molten metal, ensuring the final ingot is both chemically accurate and structurally pure.

Preserving Chemical Composition

Preventing Oxidative Loss

The most critical function of the VIF during TWIP steel production is the protection of active alloying elements. TWIP steel relies heavily on elements like manganese to achieve its high strength and ductility.

At high melting temperatures, these elements are highly reactive and prone to oxidation if exposed to air. The VIF mitigates this by operating under a vacuum or inert atmosphere, ensuring that volatile components are not lost to the atmosphere as oxides.

Controlled Atmospheric Protection

To further secure the melt, the furnace allows for the backfilling of the chamber with high-purity inert gases, such as argon.

By reducing the chamber vacuum to extremely low levels (e.g., below 15 Pa) and introducing inert gas, the system effectively neutralizes the risk of reactions with oxygen and nitrogen. This ensures the foundational purity of the steel remains intact throughout the heating cycle.

Enhancing Material Quality via Induction

Electromagnetic Stirring

Beyond simple heating, the VIF utilizes electromagnetic induction to generate eddy currents within the metal charge.

This process creates a natural stirring effect within the molten steel. This vigorous movement is essential for promoting the uniform distribution of alloying components, preventing segregation that could lead to weak points in the final material.

Ensuring High Purity

The combination of vacuum conditions and induction heating results in a cleaner final product.

The vacuum environment facilitates the removal of volatile impurities and gases that might otherwise remain trapped in the liquid steel. By minimizing non-metallic inclusions and gaseous impurities, the VIF ensures the steel meets the rigorous purity standards required for high-performance applications.

Understanding the Operational Trade-offs

Complexity of Process Control

While the VIF offers superior quality, it introduces significant operational complexity compared to standard open-air melting.

Operators must maintain rigorous control over vacuum levels and gas purity (often requiring argon purity >99.999%) to be effective. A failure in the vacuum seal or a lapse in gas quality can immediately compromise the melt, wasting expensive alloying elements like manganese.

Batch Limitation

The VIF is typically a batch processing method, which is ideal for experimental ingots or specialized high-value steels but less suited for continuous, high-volume throughput.

This makes the process inherently more time-consuming and costly per unit than conventional methods. It is a strategic choice used only when the quality and composition of the alloy are more critical than the speed of production.

Making the Right Choice for Your Goal

If you are determining whether a vacuum induction furnace is necessary for your specific steel production needs, consider the following:

- If your primary focus is Compositional Accuracy: You must use VIF to prevent the evaporation and oxidation of volatile elements like manganese and aluminum, which are critical to TWIP steel performance.

- If your primary focus is Microstructural Homogeneity: You should leverage the inductive stirring capabilities of the VIF to ensure that all alloying elements are evenly distributed throughout the ingot.

In summary, the vacuum induction furnace is not just a heater; it is a precision tool that acts as a shield against oxidation and a mixer for chemical uniformity, making it indispensable for advanced TWIP steel fabrication.

Summary Table:

| Feature | Function in TWIP Steel Production | Benefit |

|---|---|---|

| Vacuum Environment | Prevents oxidation of reactive elements like Manganese | Maintains precise chemical composition |

| Inert Gas Backfill | Neutralizes risk of atmospheric contamination | Ensures foundational purity of the alloy |

| Electromagnetic Stirring | Promotes uniform distribution of alloying components | Prevents segregation and weak points |

| De-gassing | Removes volatile impurities and trapped gases | Increases structural integrity and cleanliness |

Elevate Your Advanced Metallurgy with KINTEK

Precision is the foundation of high-performance TWIP steel. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Vacuum, CVD, and high-temperature furnace systems tailored for the most demanding lab and production environments. Whether you need to eliminate oxidative loss or ensure perfect microstructural homogeneity, our customizable solutions are designed to meet your unique metallurgical challenges.

Ready to optimize your material quality? Contact KINTEK today to discover how our high-temp vacuum systems can transform your melting process.

Visual Guide

References

- Xiaozhou Zhou, Lei Jiang. Machine-Learning-Assisted Composition Design for High-Yield-Strength TWIP Steel. DOI: 10.3390/met14080952

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the role of a vacuum arc furnace in TixNbMoTaW RHEA synthesis? Key steps for refractory alloy prep

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What industries commonly use vacuum or protective atmosphere induction furnaces? Essential for Aerospace, Medical, and More

- Why is a vacuum induction furnace necessary for Seebeck coefficient measurement? Achieve Precise Thermal Data

- What is the function of a non-consumable vacuum arc melting furnace? Synthesizing Ultra-Pure Zr2Fe-based Alloys

- What is a Vacuum Induction Melting Furnace (VIM) and what processes does it perform? Achieve Ultimate Metal Purity and Precision

- What is the function of a vacuum induction melting furnace for AlCoCrFeNi2.1? Mastering High-Entropy Alloy Production

- Why is electromagnetic stirring necessary for NbC-Cr7C3@graphene in W18Cr4V steel? Boost Alloy Performance