At its core, vacuum induction melting (VIM) is a process that uses a powerful magnetic field to melt metal inside a sealed, airless chamber. By removing the atmosphere, the process prevents contamination from elements like oxygen and nitrogen, resulting in exceptionally pure and high-performance alloys. The heating itself is contactless, generated directly within the metal, which allows for precise control over temperature and composition.

The crucial insight is that vacuum induction melting is not just a melting technique; it is a combined melting and refining process. It leverages the physics of electromagnetic induction for clean heating and a vacuum environment to actively remove dissolved gases and volatile impurities, achieving a level of quality unattainable in open-air methods.

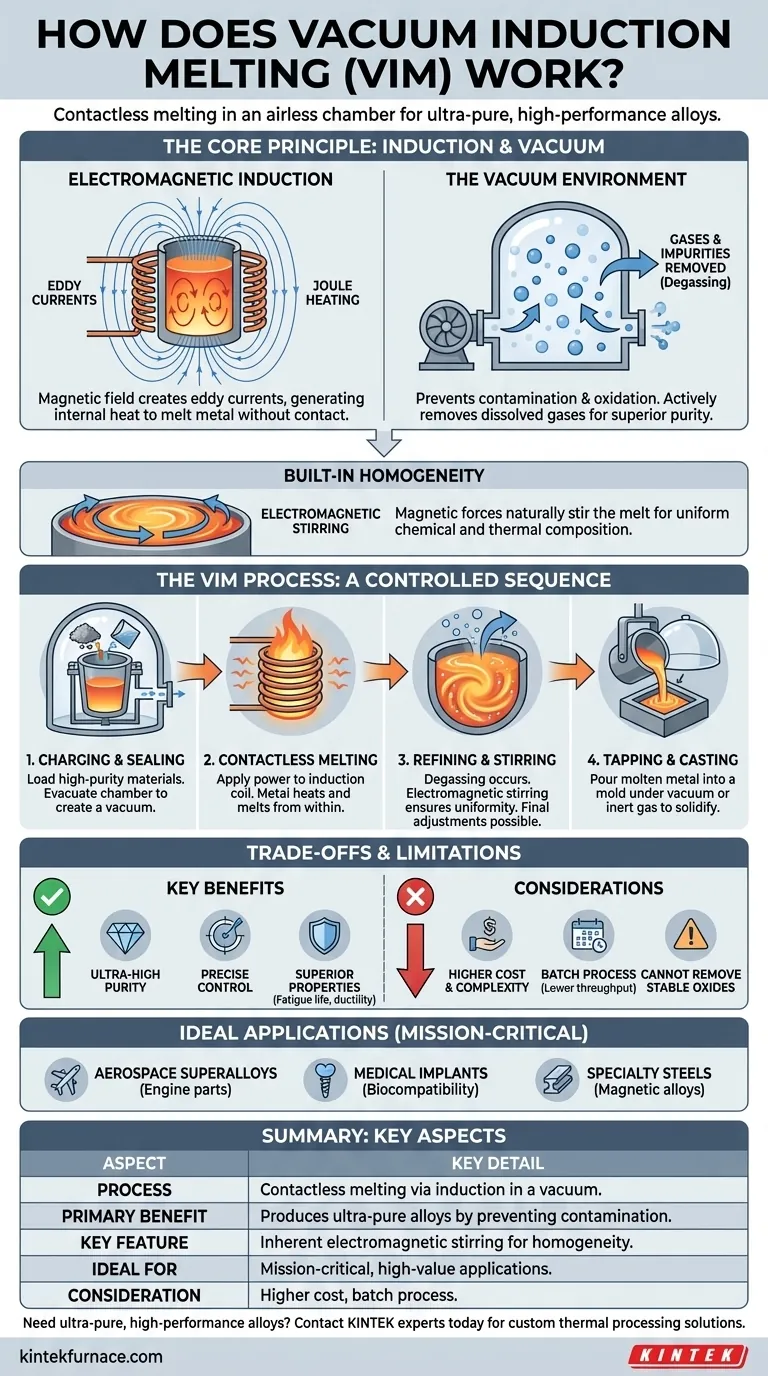

The Core Principle: Contactless Heating in a Vacuum

To understand VIM, you must grasp its two fundamental components: the vacuum and the induction. Each solves a specific problem in high-performance metal production.

How Electromagnetic Induction Works

An induction furnace generates a strong, alternating magnetic field around the metal charge. This magnetic field induces powerful electrical currents, known as eddy currents, directly within the metal.

The inherent electrical resistance of the metal causes these eddy currents to generate immense heat, a principle called Joule heating. This allows the metal to melt from the inside out without any external flame or heating element making contact.

The Role of the Vacuum

The entire process occurs within a sealed furnace chamber from which the air has been evacuated. This vacuum environment is critical for two reasons.

First, it prevents oxidation and reactions with atmospheric gases like oxygen and nitrogen, which can form undesirable impurities and inclusions in the final product.

Second, the low-pressure environment helps pull dissolved gases, such as hydrogen and nitrogen, out of the molten metal. This degassing effect significantly improves the mechanical properties of the alloy, like its fatigue life and ductility.

Built-in Stirring for Homogeneity

A unique benefit of induction is that the same magnetic forces that generate heat also create a natural electromagnetic stirring effect in the molten metal bath.

This constant motion ensures the melt remains chemically and thermally homogenous. It guarantees that alloying additions are evenly distributed and prevents temperature variations, leading to a consistent, high-quality final ingot.

The Step-by-Step VIM Process

A typical VIM cycle is a carefully controlled sequence designed to maximize purity and precision.

Step 1: Charging the Furnace

High-purity raw metals and alloying elements are loaded into a crucible inside the furnace. The furnace is then sealed and a powerful vacuum system evacuates the chamber to a specified low pressure.

Step 2: Melting the Charge

Once the target vacuum level is reached, power is applied to the induction coil. The electromagnetic field penetrates the chamber and begins to heat and melt the metal charge.

Step 3: Refining and Homogenization

As the metal becomes molten, the process enters a refining stage. The vacuum actively removes volatile impurities and dissolved gases. Simultaneously, the electromagnetic stirring ensures the melt achieves a uniform temperature and composition.

During this stage, the operator can make final chemical adjustments by adding precise amounts of elements to meet the target specification.

Step 4: Tapping and Casting

After the melt chemistry is verified, the molten metal is poured, or "tapped," from the crucible into a mold. This entire step is often performed under vacuum or in a controlled inert gas atmosphere to prevent any re-contamination before the metal solidifies.

Understanding the Trade-offs and Limitations

While VIM offers unparalleled quality, it is not a universally applicable solution. Understanding its limitations is key to making informed technical decisions.

Higher Cost and Complexity

VIM furnaces are capital-intensive, and their operation requires significant technical expertise. The need for robust vacuum systems, powerful electrical supplies, and sophisticated monitoring increases both the initial investment and ongoing maintenance costs compared to conventional furnaces.

Limited Removal of Stable Oxides

While the vacuum is excellent at removing dissolved gases and volatile elements, it cannot remove stable, non-volatile impurities like certain oxides or silicates that may have been present in the initial raw material. The quality of the input materials remains critical.

Batch Processing and Throughput

VIM is inherently a batch process. The cycle of charging, evacuating, melting, refining, and casting limits the overall production rate (throughput) compared to continuous melting processes used for high-volume commodities like standard steel.

When to Specify Vacuum Induction Melting

Choosing VIM is a strategic decision driven by the end application's performance requirements.

- If your primary focus is mission-critical superalloys for aerospace or power generation: VIM is the industry standard for the required cleanliness, strength, and fatigue resistance at extreme temperatures.

- If your primary focus is manufacturing medical implants: The unmatched purity and precise chemistry control offered by VIM are non-negotiable for ensuring biocompatibility and long-term device safety.

- If your primary focus is producing clean, high-performance specialty steels or magnetic alloys: VIM provides the tight compositional control and low gas content necessary to achieve specific magnetic or mechanical properties.

- If your primary focus is cost-effective production of structural or commercial-grade metals: VIM is almost certainly overkill; more economical methods like electric arc or basic oxygen furnaces are better suited for these applications.

Ultimately, specifying VIM is a commitment to achieving the highest possible material quality when performance and reliability cannot be compromised.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Contactless melting via electromagnetic induction inside a vacuum chamber. |

| Primary Benefit | Produces ultra-pure alloys by preventing contamination and removing dissolved gases. |

| Key Feature | Inherent electromagnetic stirring ensures a homogenous melt. |

| Ideal For | Mission-critical applications: aerospace superalloys, medical implants, specialty steels. |

| Consideration | Higher cost and complexity; a batch process best suited for high-value metals. |

Need ultra-pure, high-performance alloys for your mission-critical applications?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal processing solutions. Our expertise in high-temperature furnace technology, including custom vacuum and atmosphere systems, can help you achieve the precise material quality your projects demand.

Contact our experts today to discuss how our deep customization capabilities can meet your unique VIM requirements.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the primary advantages of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Materials

- What is the role of a vacuum induction melting furnace in Fe-C-B-Cr-W alloy production? Achieve High-Purity Homogeneity

- What is the crucible material in the induction furnace? Select the Right Crucible for Your Metal

- What role does vacuum induction melting equipment play in the preparation of CrFeNi alloys? Essential Purity Guide

- What is the working principle of a medium frequency induction furnace? Achieve Rapid, Precise Metal Melting

- What are the primary industrial applications of induction furnaces? Unlock Efficient Metal Processing Solutions

- What was the challenge in moving the ingot material into position for the vacuum induction furnace? Overcome High Moment Loads and Extreme Heat

- What are the major challenges faced by the IGBT induction melting furnace market? Navigating High Costs and Complexity