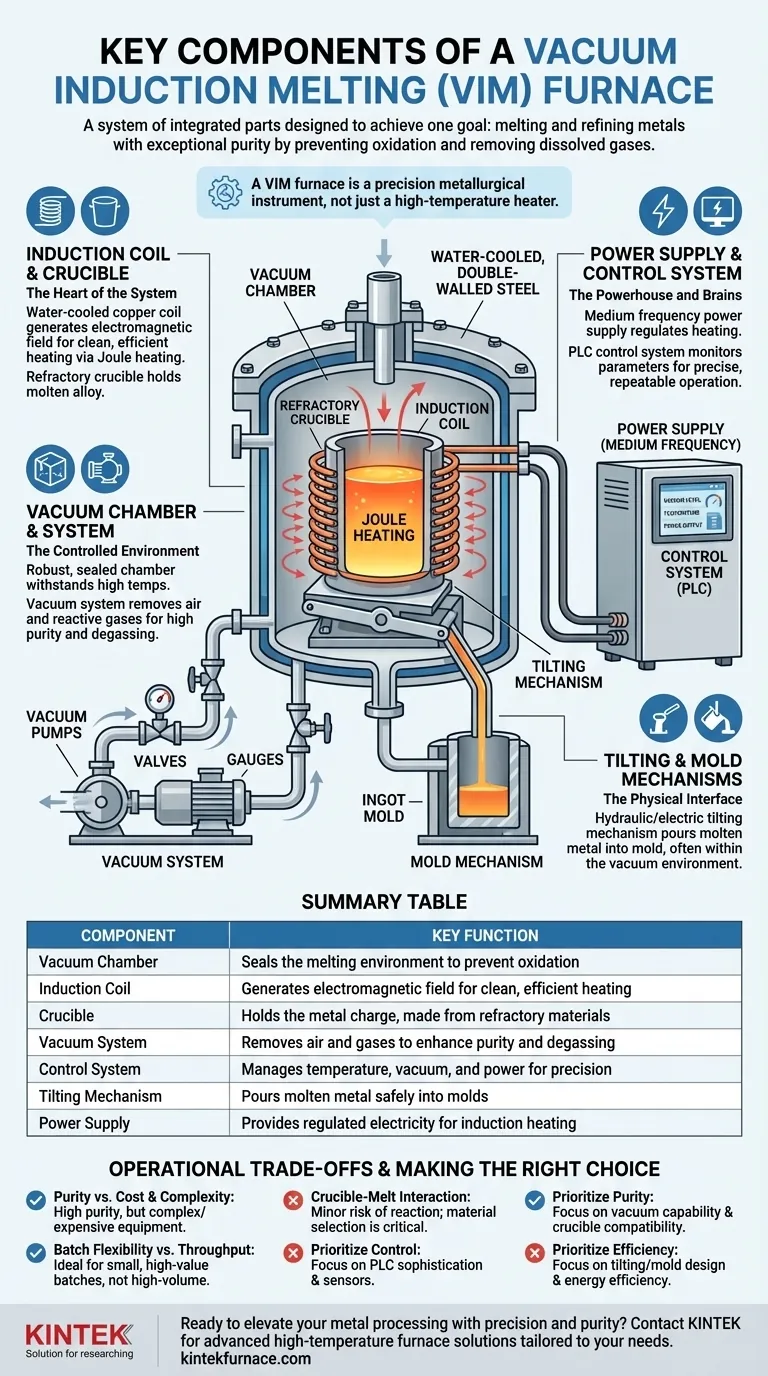

The core components of a Vacuum Induction Melting (VIM) furnace are a system of integrated parts designed to achieve a singular goal: melting and refining metals with exceptional purity. The key components are the vacuum chamber, the induction coil and its power supply, the crucible which holds the metal, the vacuum system for removing air, and the control system for managing the entire process. These elements work in concert to prevent oxidation and remove dissolved gases, which is impossible in a standard air-melting furnace.

A VIM furnace is not merely a high-temperature heater; it is a precision metallurgical instrument. Its components are engineered to create a tightly controlled environment, using electromagnetic induction for clean heating and a vacuum to control the final chemistry of the alloy.

The Anatomy of a VIM Furnace: A Functional Breakdown

Each component serves a distinct and critical function. Understanding how they interrelate is key to understanding the VIM process itself.

The Heart of the System: Induction Coil and Crucible

The induction coil is the engine of the furnace. It is a water-cooled, spiral copper tube that generates a powerful, alternating electromagnetic field when energized by the power supply.

This field induces strong electrical currents directly within the metal charge itself, a process known as Joule heating. This method is incredibly clean and efficient, as the heat is generated inside the material without any direct contact from a heating element.

The metal is held in a crucible, a container made from a refractory material like magnesia, alumina, or zirconia. The choice of crucible material is critical, as it must withstand extreme temperatures and avoid reacting with the specific molten alloy.

The Controlled Environment: Vacuum Chamber and System

The entire melting process takes place inside a robust, sealed vacuum chamber. This furnace body is typically a water-cooled, double-walled steel vessel designed to withstand both high internal temperatures and external atmospheric pressure.

The vacuum system is what makes VIM a high-purity process. It consists of a series of pumps, valves, and gauges that work to remove air and, more importantly, reactive gases like oxygen and nitrogen from the chamber before and during melting. This prevents the formation of oxides and other impurities.

This system also helps remove dissolved gases like hydrogen from the molten metal, a process known as degassing, which significantly improves the final material's mechanical properties.

The Powerhouse and Brains: Power Supply and Control System

A medium frequency power supply provides the high-current electricity required to drive the induction coil. Modern systems often use IGBT technology for precise power regulation, which directly controls the rate of heating and the final temperature of the melt.

The entire operation is managed by the electric control system. Using a PLC (Programmable Logic Controller) and a touch-screen interface, operators can monitor and regulate every critical parameter in real time, including vacuum level, temperature, and power output. This ensures the process is repeatable and precise.

The Physical Interface: Tilting and Mold Mechanisms

Once the metal is fully molten and refined, it must be poured. A hydraulic or electric furnace tilting mechanism carefully rotates the entire furnace assembly to pour the liquid metal from the crucible.

The molten metal is typically poured into a mold mechanism, also located within the vacuum chamber or in an adjacent, connected chamber. This allows the metal to be cast into a specific shape, such as an ingot, without ever being exposed to the outside atmosphere.

Understanding the Operational Trade-offs

While VIM technology offers unparalleled control, it comes with inherent trade-offs that are important to recognize.

Purity vs. Cost and Complexity

The primary benefit of VIM is producing extremely clean, high-purity alloys. However, the equipment required to achieve this—high-capacity vacuum pumps, sophisticated power supplies, and robust control systems—is significantly more complex and expensive than that of traditional air-melting furnaces.

Batch Flexibility vs. Throughput

VIM is ideal for producing smaller, high-value batches with precise chemical compositions. The process is inherently batch-oriented, and the time required to pump down the chamber, melt, refine, and cast limits its overall throughput. It is not designed for the high-volume, continuous production seen in industries like steelmaking.

Crucible-Melt Interaction

Although the process is incredibly clean, the molten metal is in direct contact with the crucible. There is always a minor risk of chemical reaction between the highly reactive liquid metal and the crucible's refractory material, which can introduce trace impurities. Selecting the correct crucible material for the specific alloy is therefore a critical process parameter.

Making the Right Choice for Your Goal

Understanding how each component contributes to the final product allows you to prioritize what matters most for your specific application.

- If your primary focus is extreme purity: Pay closest attention to the vacuum system's capability (ultimate vacuum level and pumping speed) and the crucible material's compatibility with your alloy.

- If your primary focus is process control and repeatability: The sophistication of the PLC-based control system and its sensors for precise temperature, power, and vacuum regulation is your most critical factor.

- If your primary focus is operational efficiency: The design of the furnace tilting and mold handling systems, along with the power supply's energy efficiency, are key to minimizing cycle time and operating costs.

Ultimately, mastering a VIM furnace means understanding it not as a collection of parts, but as an integrated system for total metallurgical control.

Summary Table:

| Component | Key Function |

|---|---|

| Vacuum Chamber | Seals the melting environment to prevent oxidation |

| Induction Coil | Generates electromagnetic field for clean, efficient heating |

| Crucible | Holds the metal charge, made from refractory materials |

| Vacuum System | Removes air and gases to enhance purity and degassing |

| Control System | Manages temperature, vacuum, and power for precision |

| Tilting Mechanism | Pours molten metal safely into molds |

| Power Supply | Provides regulated electricity for induction heating |

Ready to elevate your metal processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored for laboratories and metallurgical applications. Our VIM furnaces, part of a product line that includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are designed with deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our expertise can optimize your processes and deliver superior results!

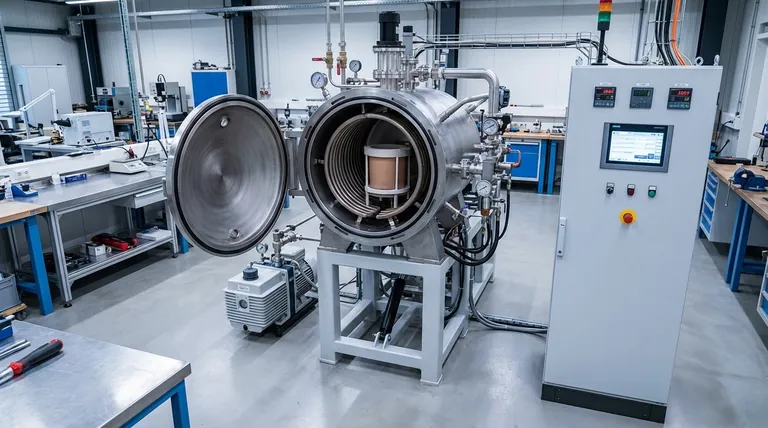

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications