At its core, a Vacuum Induction Melting (VIM) furnace is a highly specialized system that melts, refines, and alloys metals inside a tightly controlled vacuum. It uses non-contact electromagnetic induction for heating, which eliminates common sources of contamination and allows for the production of extremely high-purity, homogenous materials required for critical applications.

The true value of a VIM furnace is not simply melting metal. It is the ability to exert absolute control over the material's environment, removing reactive gases like oxygen and nitrogen to create alloys with a level of purity and compositional precision that is impossible to achieve in open-air furnaces.

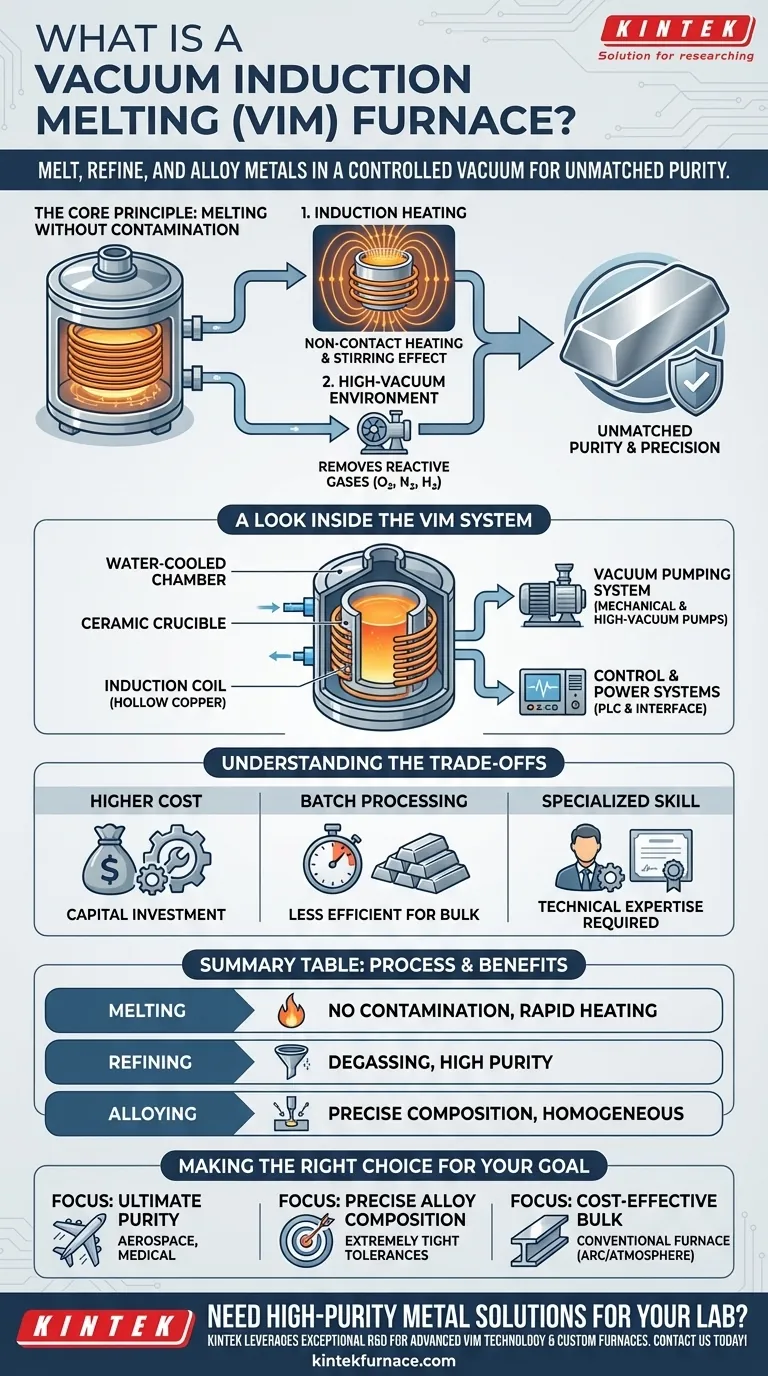

The Core Principle: Melting Without Contamination

The VIM process is defined by two fundamental technologies working in tandem: induction heating and a high-vacuum environment. This combination directly addresses the primary challenges in high-performance metallurgy.

How Induction Heating Works

An induction furnace generates a powerful, high-frequency magnetic field around the crucible containing the metal charge.

This magnetic field induces strong electrical eddy currents within the metal itself, causing it to heat rapidly and melt from the inside out. This process is clean, efficient, and provides a natural stirring effect that ensures the molten bath is perfectly mixed.

The Critical Role of the Vacuum

Before and during melting, a powerful vacuum system removes the air from the furnace chamber.

This evacuation is crucial because it eliminates oxygen, nitrogen, and other reactive atmospheric gases. By removing them, the VIM process prevents the formation of undesirable oxides and nitrides that can compromise the final material's strength and integrity.

The Result: Unmatched Purity and Precision

The vacuum environment also pulls dissolved gases, like hydrogen, out of the molten metal, a process known as degassing.

Combined with the electromagnetic stirring from the induction coil, the final product is a perfectly homogenous alloy with an exceptionally clean microstructure and precise chemical composition, meeting the tight tolerances demanded by advanced industries.

A Look Inside the VIM System

A VIM furnace is a complex system where each component serves a critical function in controlling the melting process.

The Furnace Chamber and Induction Coil

The core of the system is the water-cooled furnace body, which houses the ceramic crucible containing the metal. Wrapped around this crucible is the inductor—a coil of hollow copper tubing—which generates the magnetic field. Water flows through the coil to keep it from overheating.

The Vacuum Pumping System

This is the network of mechanical pumps and high-vacuum pumps responsible for evacuating the furnace chamber. A sophisticated series of valves and gauges allows operators to precisely control the pressure level throughout the melting and pouring cycle.

Control and Power Systems

Modern VIM furnaces are managed by a PLC (Programmable Logic Controller) and a touch-screen interface. This allows for precise, repeatable control over power input, temperature, pressure levels, and the timing of alloy additions.

Understanding the Trade-offs

While VIM technology offers unparalleled quality, it comes with specific considerations that make it unsuitable for every application.

Higher Initial Cost and Complexity

VIM furnaces are sophisticated pieces of equipment. The need for robust vacuum systems, precise power controls, and water-cooling infrastructure results in a significantly higher capital investment compared to standard atmosphere furnaces.

Batch Processing Limitations

By its nature, VIM is a batch process. The chamber must be loaded, sealed, evacuated, run through the melt cycle, and then cooled before the next batch can begin. This makes it less efficient for high-volume, continuous production of lower-grade metals.

Specialized Operational Skill

Operating and maintaining a VIM furnace requires a higher level of technical expertise. Staff must be trained in vacuum technology, high-power electrical systems, and the specific metallurgical processes involved to ensure both safety and product quality.

Making the Right Choice for Your Goal

Selecting a VIM furnace depends entirely on the required quality and performance of the end material.

- If your primary focus is ultimate material purity: For aerospace superalloys, medical implants, or sputtering targets, VIM is essential for removing reactive gases and achieving the required cleanliness.

- If your primary focus is precise alloy composition: For applications needing extremely tight compositional tolerances, VIM's controlled environment and stirring action provide unmatched accuracy.

- If your primary focus is cost-effective bulk melting: For general structural steel, standard aluminum casting, or recycling scrap, a conventional arc or atmosphere induction furnace is a more practical and economical choice.

Ultimately, a VIM furnace provides absolute control over the molten state, transforming high-performance metal production from a process of refinement into a science of creation.

Summary Table:

| Process | Key Features | Benefits |

|---|---|---|

| Melting | Induction heating in vacuum | No contamination, rapid heating |

| Refining | Degassing and impurity removal | High purity, clean microstructure |

| Alloying | Precise compositional control | Homogeneous materials, tight tolerances |

Need high-purity metal solutions for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your material production with tailored VIM technology!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications