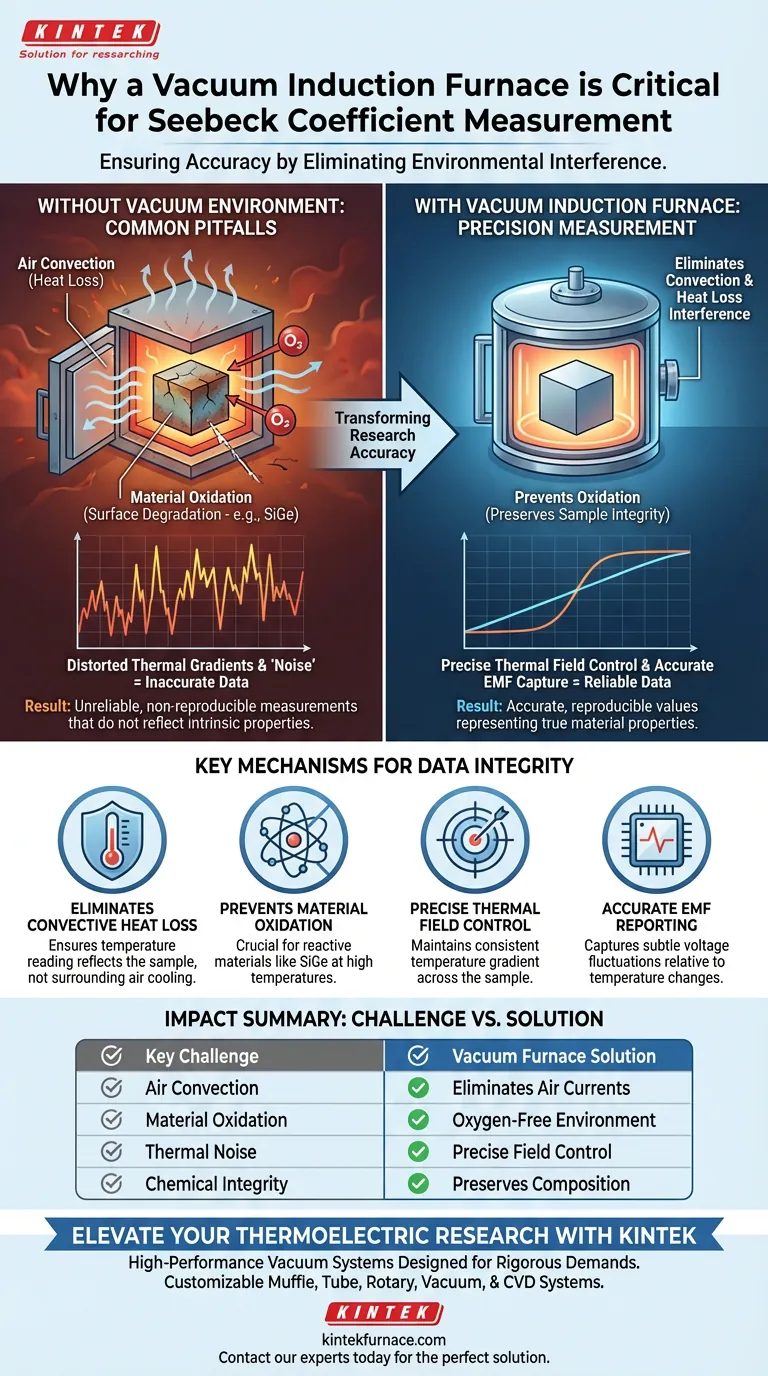

A vacuum induction furnace is critical for accurate measurement because it isolates the test sample from environmental interference that distorts data. Specifically, it eliminates heat loss caused by air convection and prevents the oxidation of sensitive materials like Silicon-Germanium (SiGe) during high-temperature testing. This isolation allows for the precise thermal field control necessary to capture accurate electromotive force fluctuations.

The reliability of Seebeck coefficient data relies entirely on maintaining a stable relationship between temperature and voltage. A vacuum environment is the only way to eliminate convective interference and chemical degradation, ensuring the measured values represent the material's intrinsic properties.

The Role of Environmental Isolation

To understand why a vacuum is necessary, you must look at the variables that corrupt high-temperature measurements.

Eliminating Convective Heat Loss

In a standard environment, air moves. As the sample heats up, air currents (convection) carry heat away unpredictably.

This creates thermal noise that disrupts the measurement of the temperature gradient. By removing the air, the vacuum induction furnace eliminates heat loss interference, ensuring that the temperature reading reflects the sample, not the cooling effect of the surrounding air.

Preventing Material Oxidation

Many thermoelectric materials, such as Silicon-Germanium (SiGe), are highly reactive at high temperatures.

If oxygen is present, the surface of the sample will oxidize. This chemical change alters the material's properties mid-test. The vacuum environment prevents this oxidation, preserving the integrity of the sample throughout the heating cycle.

Precision in Data Capture

The goal of the measurement is to correlate a specific temperature change with a specific voltage change.

Precise Thermal Field Control

Accuracy requires a stable and controllable thermal field.

The vacuum environment removes external thermal variables, allowing the furnace to maintain precise thermal field control. This stability is required to generate a consistent temperature gradient across the sample.

Accurate EMF Reporting

The Seebeck coefficient is derived from electromotive force (EMF) fluctuations.

When combined with precision probes and thermocouples, the vacuum environment allows for the accurate capture of EMF fluctuations relative to temperature changes. This results in data that is both reliable and reproducible.

Common Pitfalls in Non-Vacuum Environments

Understanding what happens without a vacuum highlights why this specific equipment is necessary.

Distorted Thermal Gradients

Without a vacuum, air convection creates unstable thermal gradients.

This leads to fluctuating temperature readings that do not align with the voltage generated by the material. The resulting calculation of the Seebeck coefficient will be mathematically incorrect due to this "noise."

Surface Degradation Errors

Testing SiGe or similar alloys in air leads to immediate surface degradation.

Oxidation creates a "skin" on the material with different electrical properties than the core. This forces the sensors to measure a composite of the oxide and the material, rather than the intrinsic properties of the thermoelectric material itself.

Making the Right Choice for Your Goal

When configuring your testing setup, you must prioritize environmental control based on your specific material needs.

- If your primary focus is Data Accuracy: Ensure your setup eliminates air convection to prevent heat loss from skewing your thermal gradient readings.

- If your primary focus is Material Integrity: You must use a vacuum environment for materials like SiGe to prevent high-temperature oxidation from altering the sample's chemical structure.

The vacuum induction furnace is not just a heating element; it is a stabilization tool that guarantees the physics of your measurement remain valid under extreme conditions.

Summary Table:

| Key Challenge | Vacuum Induction Furnace Solution | Impact on Data Accuracy |

|---|---|---|

| Air Convection | Eliminates air currents and heat loss | Ensures stable and predictable thermal gradients |

| Material Oxidation | Provides oxygen-free environment | Prevents surface degradation of materials like SiGe |

| Thermal Noise | Precise thermal field control | Enables accurate capture of subtle EMF fluctuations |

| Chemical Integrity | Preserves sample composition | Guarantees results represent intrinsic material properties |

Elevate Your Thermoelectric Research with KINTEK

Don’t let environmental interference compromise your material research. KINTEK provides high-performance vacuum systems designed for the rigorous demands of thermoelectric testing.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your unique laboratory needs. Whether you are testing sensitive SiGe alloys or advanced thermoelectric materials, our furnaces deliver the precise thermal field control required for reliable, reproducible data.

Ready to optimize your testing accuracy? Contact our technical experts today to find the perfect high-temperature furnace solution for your lab.

Visual Guide

References

- The Maximums of the Seebeck Coefficient and Figure of Merit of Thermoelectric. DOI: 10.64030/3065-906x.02.01.01

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is an induction heater circuit and what is its primary use? Discover Efficient, Contactless Heating Solutions

- How does the vacuum environment contribute to metal quality in VIM furnaces? Achieve Superior Purity and Performance

- What is a vacuum induction furnace and how does it differ from other vacuum sintering furnaces? Discover the Key Differences

- How does an integrated system of in-situ neutron diffraction, high-frequency induction heating, and deformation devices address technical challenges in metallurgical research? Uncover Real-Time Microstructural Evolution

- What solutions are implemented for vacuum induction melting (VIM)? Achieve Superior Alloy Purity and Performance

- Why is a Vacuum Induction Melting (VIM) furnace essential? Secure Superalloy Purity and Performance

- What safety measures should be taken when operating an induction furnace for melting PGMs? Ensure Operator and Material Safety

- What factors should be considered when selecting a graphite crucible for an induction furnace? Ensure Melt Purity and Safety