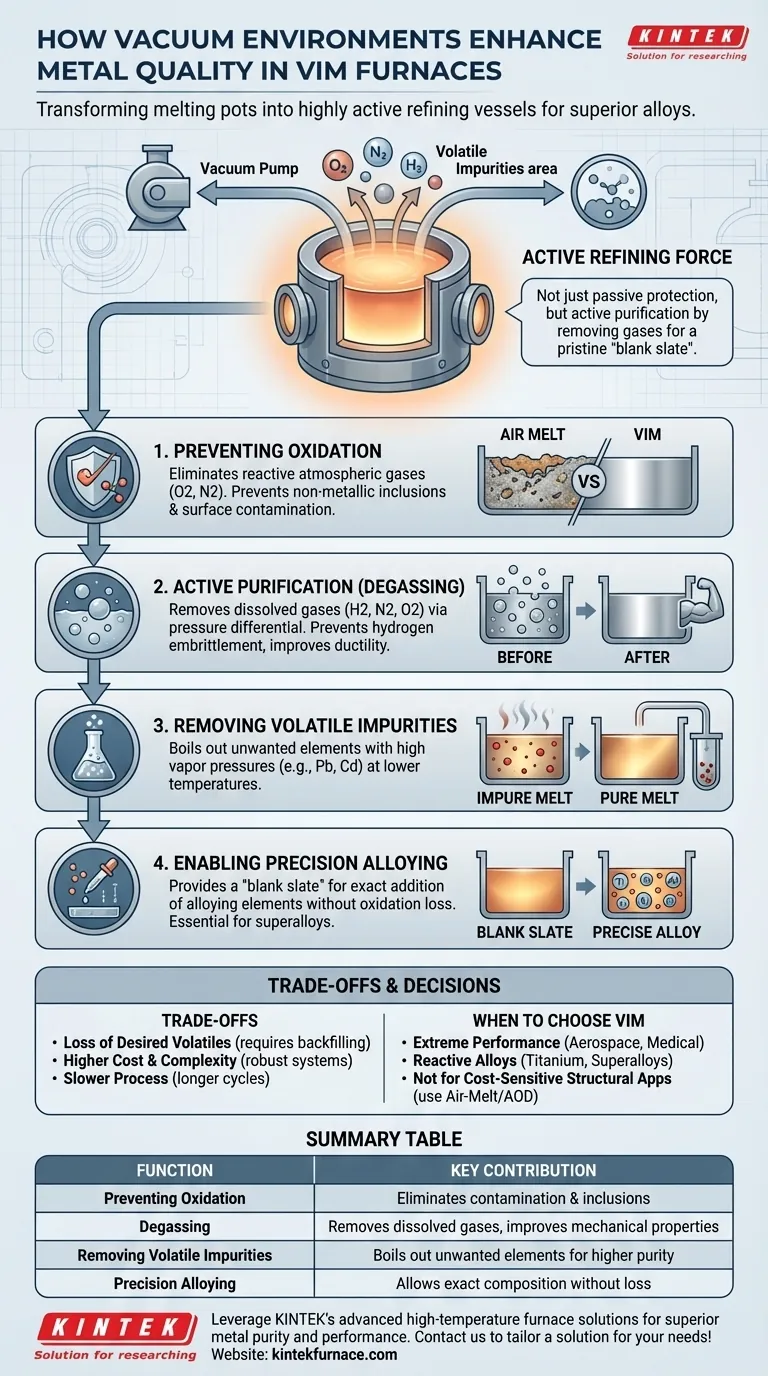

At its core, a vacuum environment transforms a VIM (Vacuum Induction Melting) furnace from a simple melting pot into a highly active refining vessel. By removing atmospheric gases, the vacuum fundamentally alters the chemical and physical processes within the molten metal, enabling the creation of alloys with superior purity, strength, and consistency that are unachievable through conventional air-melting techniques.

The crucial insight is that the vacuum’s role is not merely passive protection. It is an active force that purifies the melt by pulling out dissolved gases and volatile impurities, creating a pristine "blank slate" for precise and repeatable alloy engineering.

The Four Core Functions of Vacuum in Metal Refining

The vacuum environment's contribution to metal quality can be understood through four distinct but interconnected functions. Each plays a critical role in producing a final product with superior metallurgical properties.

Function 1: Preventing Oxidation and Contamination

At the extreme temperatures required for melting, most metals are highly reactive with the gases in our atmosphere, particularly oxygen and nitrogen.

This reaction, known as oxidation, creates non-metallic inclusions and impurities (like rust on iron) that become trapped in the solidified metal, creating weak points and compromising performance.

A vacuum furnace physically removes these reactive gases from the chamber. By eliminating the reactants, it prevents oxidation from ever occurring, ensuring the surface and bulk of the metal remain clean.

Function 2: Active Purification Through Degassing

Molten metal acts like a sponge for gases, dissolving significant amounts of hydrogen, nitrogen, and oxygen from its raw materials and environment.

Hydrogen is particularly damaging, leading to a phenomenon called hydrogen embrittlement, which severely reduces a metal's ductility and toughness, making it prone to cracking under stress.

The low-pressure environment of a vacuum creates a powerful pressure differential. This forces dissolved gases to come out of the solution and be pumped away, effectively degassing the melt and dramatically improving the final mechanical properties, including fatigue strength and plasticity.

Function 3: Removing Volatile Impurities

Beyond dissolved gases, raw materials can contain trace amounts of other undesirable elements with high vapor pressures (meaning they boil at lower temperatures).

Under vacuum, the boiling point of these elements is significantly reduced. This allows unwanted volatile impurities like lead, cadmium, or bismuth to literally boil out of the molten metal bath.

This process is a form of distillation that further purifies the base metal, resulting in an alloy with higher cleanliness and more predictable performance.

Function 4: Enabling Precision Alloying

After the vacuum has removed unwanted atmospheric gases and impurities, the molten metal is in a pristine, highly controlled state.

This "blank slate" allows for the precise introduction of specific alloying elements in exact quantities. Because there is no oxygen or nitrogen to react with, these valuable elements are not lost to oxidation, ensuring the final chemical composition is exactly what was designed.

This level of control is essential for creating complex, high-performance materials like superalloys, where even minor variations in composition can drastically alter their properties.

Understanding the Trade-offs

While VIM offers unparalleled quality, it is a specialized process with specific trade-offs that must be considered.

Loss of Desired Volatile Elements

The vacuum cannot distinguish between desirable and undesirable volatile elements. Alloying elements with high vapor pressures, such as manganese, can also be removed during the process.

This requires careful process control, such as backfilling the furnace with a partial pressure of an inert gas like argon, to suppress the evaporation of beneficial elements while still removing harmful ones.

Higher Cost and Complexity

VIM furnaces are significantly more complex and expensive to build and operate than their atmospheric counterparts.

The need for robust vacuum chambers, powerful pumping systems, and longer cycle times to achieve and maintain low pressures makes the process inherently slower and more costly.

Not a Universal Solution

The immense benefits of vacuum melting are most critical for materials where purity and performance are paramount.

For many general-purpose applications, the material properties achieved through less expensive air-melting or argon oxygen decarburization (AOD) refining are perfectly adequate. VIM is often reserved for the most demanding industries.

Making the Right Choice for Your Goal

Specifying a vacuum-melted material is a decision driven by the end-use requirements for performance and reliability.

- If your primary focus is extreme performance and reliability (e.g., aerospace, medical implants): VIM is essential for its ability to produce ultra-clean material free from defects and hydrogen embrittlement.

- If your primary focus is creating a specific, reactive alloy (e.g., titanium alloys, superalloys): The controlled VIM environment is the only way to prevent contamination and precisely hit the target chemical composition.

- If your primary focus is cost-sensitive structural applications: Conventional air-melted or AOD-refined materials often provide the necessary performance at a much lower cost.

Ultimately, leveraging a vacuum environment allows you to engineer a superior material by fundamentally controlling its chemistry from its most basic molten state.

Summary Table:

| Function | Key Contribution |

|---|---|

| Preventing Oxidation | Eliminates atmospheric gases to avoid contamination and inclusions |

| Degassing | Removes dissolved hydrogen, nitrogen, and oxygen to improve mechanical properties |

| Removing Volatile Impurities | Boils out unwanted elements like lead and cadmium for higher purity |

| Precision Alloying | Allows exact addition of alloying elements without loss to oxidation |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in aerospace, medical implants, or specialized alloy development, our VIM furnaces can help you achieve superior metal purity and performance. Contact us today to discuss how we can tailor a solution for your needs!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity