In short, vacuum and protective atmosphere induction furnaces are essential in any industry where material purity and performance are paramount. They are most commonly used in the aerospace, medical, electronics, energy, and automotive sectors for creating highly specialized metals, alloys, and components that cannot be produced in a standard atmosphere.

The core purpose of using a vacuum or a controlled atmosphere is to protect molten metal from contamination. By removing reactive gases like oxygen and nitrogen, these furnaces prevent oxidation and enable the production of ultra-pure, high-performance materials with superior mechanical properties.

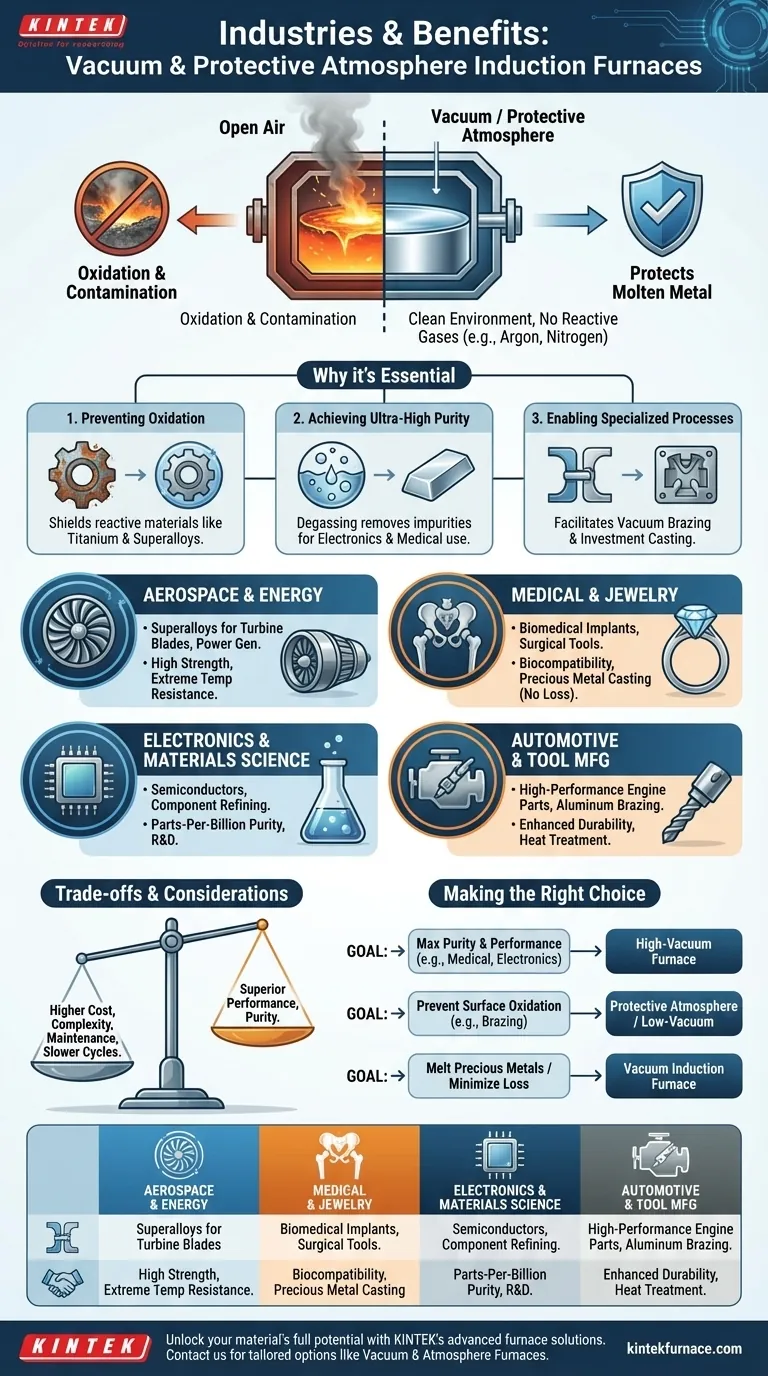

Why a Controlled Atmosphere is Essential

At the high temperatures required for melting metal, most materials react aggressively with the air around them. A vacuum or protective gas atmosphere solves this fundamental problem, which is critical for advanced manufacturing.

Preventing Oxidation and Contamination

Many advanced materials, such as titanium alloys and nickel-based superalloys, will instantly oxidize when melted in open air. This contamination degrades their structural integrity and performance.

A vacuum removes the air, while a protective atmosphere (using inert gases like argon or nitrogen) displaces it. Both methods create a clean environment that shields the molten metal, ensuring its chemical composition remains unchanged.

Achieving Ultra-High Purity

The vacuum environment does more than just prevent new contamination; it actively purifies the metal. Under vacuum, dissolved gases like oxygen and hydrogen are pulled out of the molten bath.

This degassing process is crucial for applications in electronics and medical implants, where even trace amounts of impurities can cause component failure or biocompatibility issues.

Enabling Specialized Processes

Certain manufacturing processes are only possible in a controlled environment. For example, vacuum brazing joins complex parts without using flux, creating stronger and cleaner joints for components like automotive aluminum parts.

Similarly, investment casting of aerospace components requires a vacuum to ensure the molten metal fills every intricate detail of the mold without trapping gas or forming oxide defects.

Key Industry Applications in Detail

The need for purity and performance drives the adoption of these furnaces across several high-stakes industries.

Aerospace and Energy

These sectors rely on superalloys for components that must withstand extreme temperatures and stresses, such as jet engine turbine blades and power generation equipment.

Vacuum induction melting (VIM) is the standard for producing the flawless, high-strength alloys required for these critical applications, where material failure is not an option.

Medical and Jewelry

The medical field uses vacuum furnaces to produce biomedical implants (like hip joints) and high-quality surgical instruments from materials like titanium and cobalt-chrome. The process guarantees the purity and biocompatibility needed for safe use within the human body.

In the jewelry industry, vacuum melting is used for casting precious metals like platinum and gold, preventing material loss through oxidation and ensuring a high-quality final product.

Electronics and Materials Science

Manufacturing semiconductors and other electronic components requires metals of exceptional purity. Vacuum furnaces are used to refine materials to the "parts-per-billion" level of purity needed for these applications.

Research and materials science labs also use smaller atmosphere furnaces to develop new alloys and study material properties in a precisely controlled environment.

Automotive and Tool Manufacturing

In the automotive industry, these furnaces are used to braze aluminum parts and produce high-performance engine components. They are also used in tool manufacturing for the heat treatment of high-speed steel and other tool materials, enhancing their durability and lifespan.

Understanding the Trade-offs

While indispensable for certain applications, these advanced furnaces come with specific considerations that make them unsuitable for bulk, low-cost metal production.

Higher Initial Cost and Complexity

The addition of vacuum pumps, seals, and control systems makes these furnaces significantly more expensive to purchase and install than their open-air counterparts. Operation also requires more specialized training.

Slower Cycle Times

Achieving a deep vacuum is not instantaneous. The time required to pump down the chamber before melting and backfill it after casting adds to the overall cycle time, which can limit production throughput.

Increased Maintenance Requirements

Vacuum systems demand rigorous and consistent maintenance. Seals, pumps, and gauges must be kept in perfect working order to prevent leaks and ensure the integrity of the controlled atmosphere.

Making the Right Choice for Your Goal

The decision to use a vacuum or protective atmosphere furnace is driven entirely by the material requirements of the final product.

- If your primary focus is maximum purity and performance: A high-vacuum induction furnace is non-negotiable for reactive metals, superalloys, and materials for medical or electronic use.

- If your primary focus is preventing surface oxidation for processes like brazing: A protective inert gas atmosphere or a low-vacuum furnace is often the most practical and cost-effective solution.

- If your primary focus is melting precious metals or standard alloys with minimal loss: A vacuum induction furnace provides the ideal environment to maintain material value and quality.

Ultimately, choosing the right atmospheric conditions is fundamental to unlocking the full potential of advanced materials.

Summary Table:

| Industry | Key Applications | Key Benefits |

|---|---|---|

| Aerospace | Jet engine turbine blades, superalloys | High strength, oxidation prevention |

| Medical | Biomedical implants, surgical instruments | Biocompatibility, ultra-high purity |

| Electronics | Semiconductors, component refining | Parts-per-billion purity, degassing |

| Energy | Power generation equipment | Flawless alloys, extreme temperature resistance |

| Automotive | Engine components, aluminum brazing | Enhanced durability, clean joints |

| Jewelry | Precious metal casting | Material loss prevention, high quality |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for industries such as aerospace, medical, and electronics. Contact us today to discuss how our solutions can enhance your material purity and performance!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications