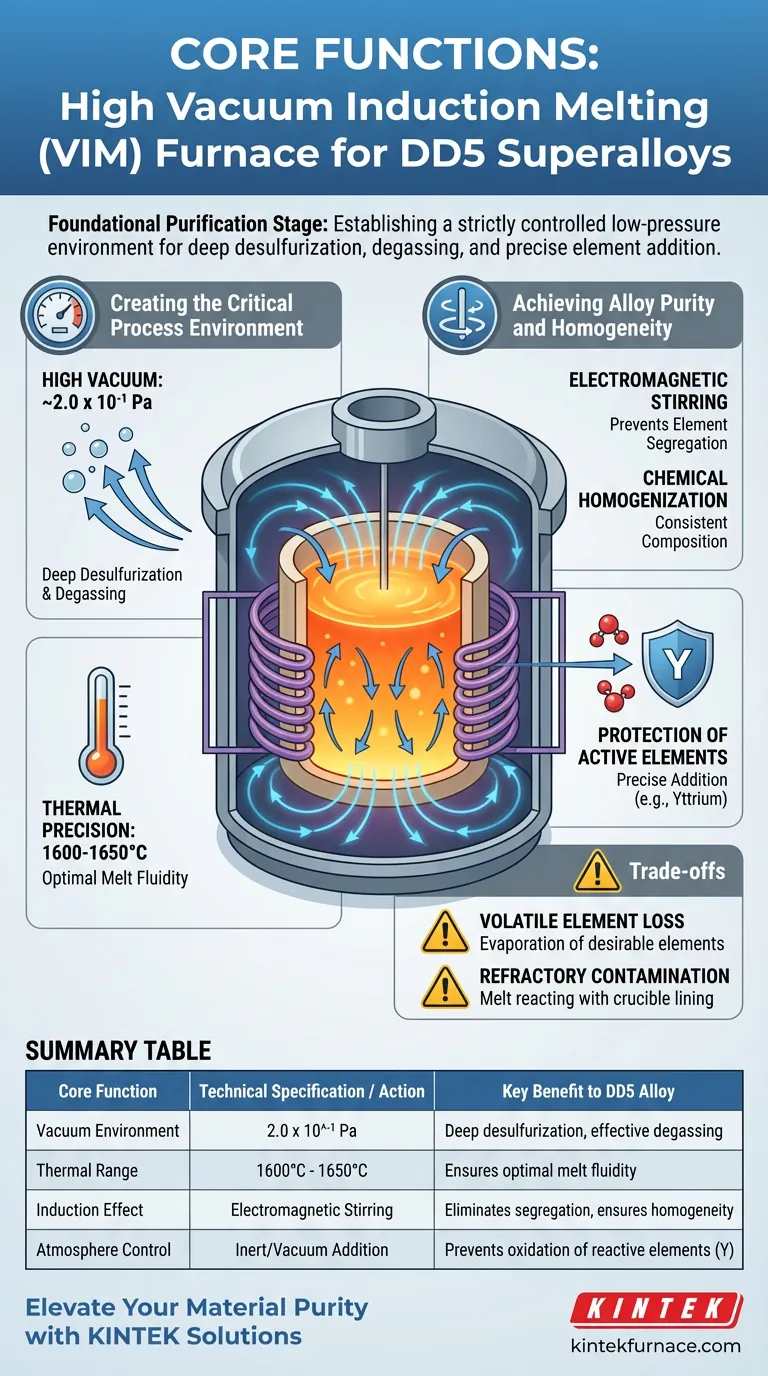

The High Vacuum Induction Melting (VIM) furnace serves as the foundational purification stage for DD5 superalloys. It functions by establishing a strictly controlled low-pressure environment, typically around 2.0 x 10^-1 Pa, while heating the alloy to temperatures between 1600 and 1650 degrees Celsius. This equipment is essential for achieving deep desulfurization, degassing the melt, and enabling the precise addition of reactive elements without oxidation.

The core value of the VIM furnace lies in its ability to simultaneously purify the metal matrix and protect highly reactive elements. By combining high vacuum with electromagnetic stirring, it ensures the chemical homogeneity and low impurity levels required for the structural integrity of DD5 superalloys.

Creating the Critical Process Environment

The Role of High Vacuum

The VIM furnace operates at a specific pressure of approximately 2.0 x 10^-1 Pa.

This low-pressure environment is the primary mechanism for degassing, effectively pulling gaseous impurities out of the molten metal.

Crucially, this vacuum level facilitates deep desulfurization, a purification step necessary to remove sulfur, which is detrimental to the alloy's mechanical properties.

Thermal Precision

Processing DD5 superalloys requires sustaining high temperatures ranging from 1600 to 1650 degrees Celsius.

Maintaining this specific window ensures the melt is fluid enough for purification reactions to occur efficiently without overheating the material or damaging the furnace lining.

Achieving Alloy Purity and Homogeneity

Electromagnetic Stirring

A distinct advantage of the VIM process is the electromagnetic stirring effect generated naturally by the induction heating coils.

This force continuously agitates the molten pool, preventing the segregation of heavy and light elements.

Chemical Homogenization

The constant movement provided by electromagnetic stirring drives chemical homogenization throughout the entire melt.

This ensures that every section of the ingot has a consistent composition, which is vital for the performance of complex alloys like DD5.

Protection of Active Elements

The VIM environment allows for the precise addition of active elements, specifically yttrium (Y), which is highly reactive to oxygen.

By eliminating atmospheric oxygen, the furnace prevents the oxidative loss of these critical additions, ensuring they remain in the alloy to perform their intended function rather than turning into slag or oxide inclusions.

Understanding the Trade-offs

Volatile Element Loss

While the high vacuum is excellent for removing gaseous impurities, it does not discriminate against desirable volatile elements.

Operators must carefully manage pressure and temperature to prevent the evaporation of necessary alloying elements that have high vapor pressures.

Refractory Contamination

Despite the purity of the vacuum, the molten metal is still in contact with the ceramic crucible.

Prolonged holding times at peak temperatures (1650°C) can increase the risk of the melt reacting with the crucible lining, potentially introducing ceramic inclusions into the alloy.

Making the Right Choice for Your Goal

If your primary focus is Alloy Cleanliness: Prioritize the vacuum level capabilities to ensure maximum degassing and deep desulfurization efficiency.

If your primary focus is Compositional Accuracy: Focus on the precise control of the induction stirring and temperature to protect reactive additions like Yttrium from oxidation or segregation.

The VIM furnace is not just a melting vessel; it is a complex chemical reactor that defines the baseline purity and performance potential of the final DD5 component.

Summary Table:

| Core Function | Technical Specification / Action | Key Benefit to DD5 Alloy |

|---|---|---|

| Vacuum Environment | 2.0 x 10^-1 Pa | Deep desulfurization and effective degassing of impurities |

| Thermal Range | 1600℃ - 1650℃ | Ensures optimal melt fluidity for purification reactions |

| Induction Effect | Electromagnetic Stirring | Eliminates element segregation; ensures chemical homogeneity |

| Atmosphere Control | Inert/Vacuum Addition | Prevents oxidation of reactive elements like Yttrium (Y) |

Elevate Your Material Purity with KINTEK Solutions

Maximize the performance of your DD5 superalloys with our advanced high-temperature melting systems. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific research or production requirements. Whether you need precise thermal control or superior chemical homogeneity, our lab furnaces deliver the reliability your project demands. Contact our technical experts today to discuss your unique needs and discover how KINTEK can enhance your material processing efficiency.

Visual Guide

References

- Fuwei Wang, Hu Zhang. The Influence of Yttrium Content and Ceramic Crucible Materials on Desulfurization during Vacuum Induction Melting of DD5 Superalloys. DOI: 10.3390/met14030353

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does electromagnetic induction stirring assist in inclusion removal? Boost Purity in Vacuum Cold Crucible Furnaces

- What are eddy currents and how are they generated in an induction heater? | Efficient Heating Explained

- How does the vacuum chamber in a vacuum casting furnace function? Unlock Purity and Performance in Metal Casting

- What are the advantages of induction heating over traditional heating methods? Faster, Cleaner, and More Efficient

- How is the semi-levitation effect generated in induction cold crucible melting? Unlock Ultra-Pure Alloy Synthesis

- What materials cannot be induction heated? The Key Role of Electrical Conductivity

- Which is better: induction furnace or electric arc furnace? The right tool for your metallurgical mission.

- What role does an induction vacuum furnace play in Yttrium-modified H13 steel? Master Precision Alloy Melting