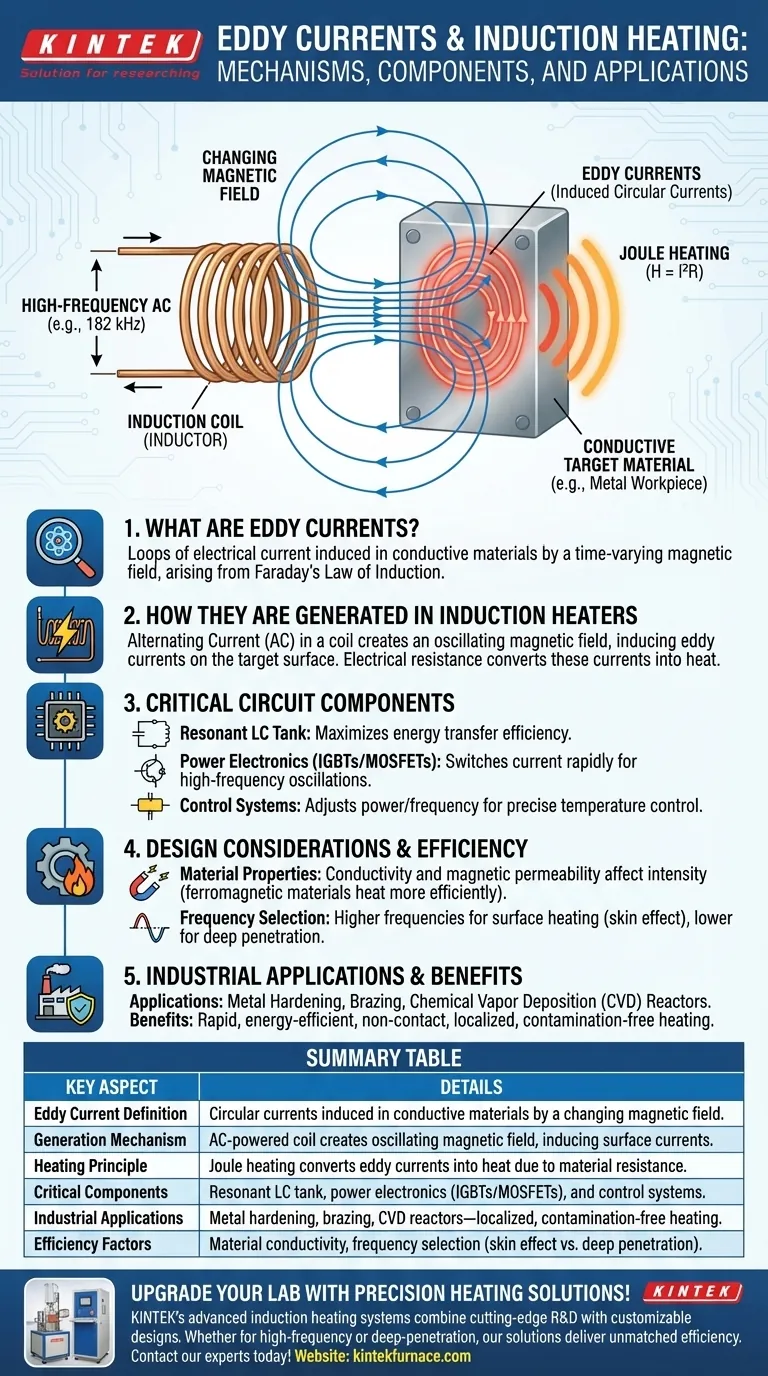

Eddy currents are circular electric currents induced within conductive materials when exposed to a changing magnetic field, primarily through electromagnetic induction. In induction heaters, these currents are generated by alternating current (AC) passing through a coil, creating a fluctuating magnetic field that penetrates the target material. The resistance of the material converts the eddy currents into heat via Joule heating, enabling precise and efficient heating. This process is controlled by circuits that optimize frequency, power, and resonance, making induction heaters valuable in industrial applications like chemical vapor deposition reactors.

Key Points Explained:

-

Definition of Eddy Currents

- Eddy currents are loops of electrical current induced within conductive materials (e.g., metals) when exposed to a changing magnetic field.

- They arise from Faraday’s Law of Induction: a time-varying magnetic field generates an electromotive force (EMF), causing current flow in the material.

-

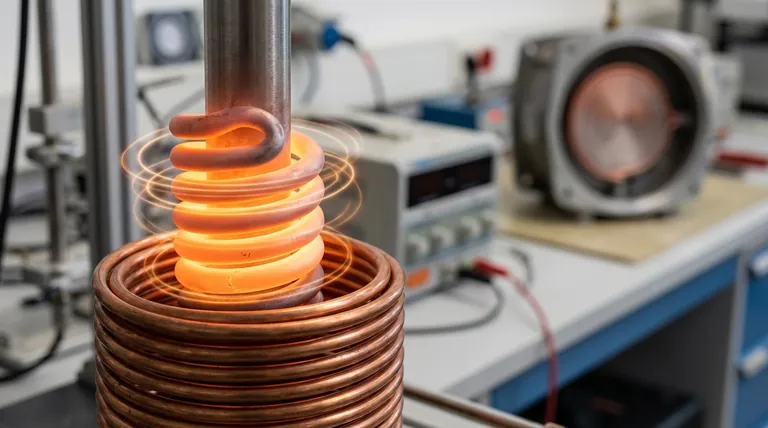

Generation in Induction Heaters

- Coil and Alternating Current (AC): An induction heater uses a coil (inductor) energized by high-frequency AC (e.g., 182 kHz in the example). The AC creates a rapidly oscillating magnetic field around the coil.

- Electromagnetic Induction: When a conductive material (e.g., a metal workpiece) is placed near the coil, the changing magnetic field induces eddy currents on the material’s surface.

- Joule Heating: These currents encounter resistance in the material, converting electrical energy into heat (H = I²R). This is the core heating mechanism.

-

Role of Circuit Components

- Resonant LC Tank: The coil and capacitors form a resonant circuit tuned to a specific frequency (e.g., 182 kHz). This maximizes energy transfer efficiency.

- Power Electronics (IGBTs/MOSFETs): Transistors switch the current rapidly to maintain high-frequency oscillations in the coil.

- Control Systems: Microcontrollers and sensors (e.g., thermocouples) adjust power and frequency to achieve precise temperature control.

-

Applications and Efficiency

- Induction heaters are used in industrial processes like metal hardening, brazing, and chemical vapor deposition reactors, where localized, contamination-free heating is critical.

- Advantages include rapid heating, energy efficiency (minimal heat loss to surroundings), and no direct contact between the coil and target material.

-

Design Considerations

- Material Properties: Conductivity and magnetic permeability affect eddy current intensity. Ferromagnetic materials heat more efficiently due to additional hysteresis losses.

- Frequency Selection: Higher frequencies (kHz–MHz) generate surface-level heating (skin effect), while lower frequencies penetrate deeper.

By understanding these principles, equipment purchasers can select induction heaters tailored to their specific material and process requirements, balancing power, frequency, and control features.

Summary Table:

| Key Aspect | Details |

|---|---|

| Eddy Current Definition | Circular currents induced in conductive materials by a changing magnetic field. |

| Generation Mechanism | AC-powered coil creates oscillating magnetic field, inducing surface currents. |

| Heating Principle | Joule heating converts eddy currents into heat due to material resistance. |

| Critical Components | Resonant LC tank, power electronics (IGBTs/MOSFETs), and control systems. |

| Industrial Applications | Metal hardening, brazing, CVD reactors—localized, contamination-free heating. |

| Efficiency Factors | Material conductivity, frequency selection (skin effect vs. deep penetration). |

Upgrade your lab with precision heating solutions!

KINTEK’s advanced induction heating systems combine cutting-edge R&D with customizable designs to meet your exact experimental needs. Whether you require high-frequency surface heating or deep-penetration thermal processing, our Molybdenum Disilicide heating elements and Silicon Carbide thermal systems deliver unmatched efficiency.

Contact our experts today to tailor a solution for your application!

Products You Might Be Looking For:

High-performance vacuum observation windows for process monitoring

Precision vacuum electrode feedthroughs for high-power applications

Durable stainless steel vacuum valves for system control

Silicon Carbide heating elements for extreme-temperature furnaces

Molybdenum Disilicide heating elements for oxidation-resistant performance

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability