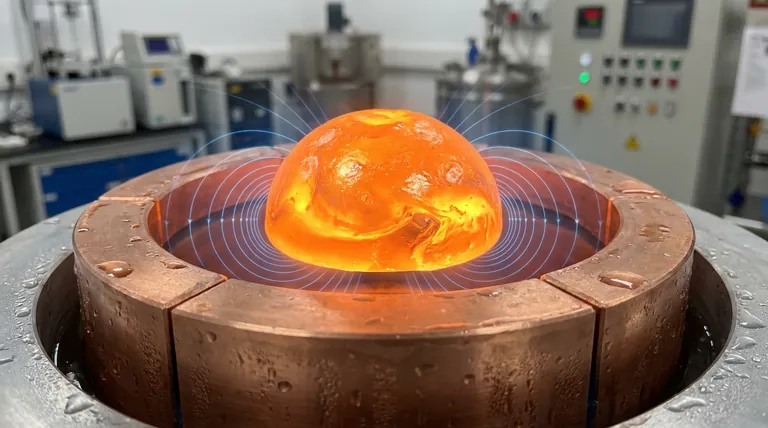

The semi-levitation effect is generated by powerful electromagnetic forces inherent to the induction furnace system. These forces act physically on the molten material, pushing it inward and causing it to partially separate from the water-cooled crucible walls. This separation creates a gap between the vessel and the material, reducing physical contact during the melting process.

The semi-levitation effect acts as a barrierless container, using magnetic pressure to isolate the melt from the crucible walls. This simultaneously prevents heat loss and contamination while driving the intense mixing required for complex alloy synthesis.

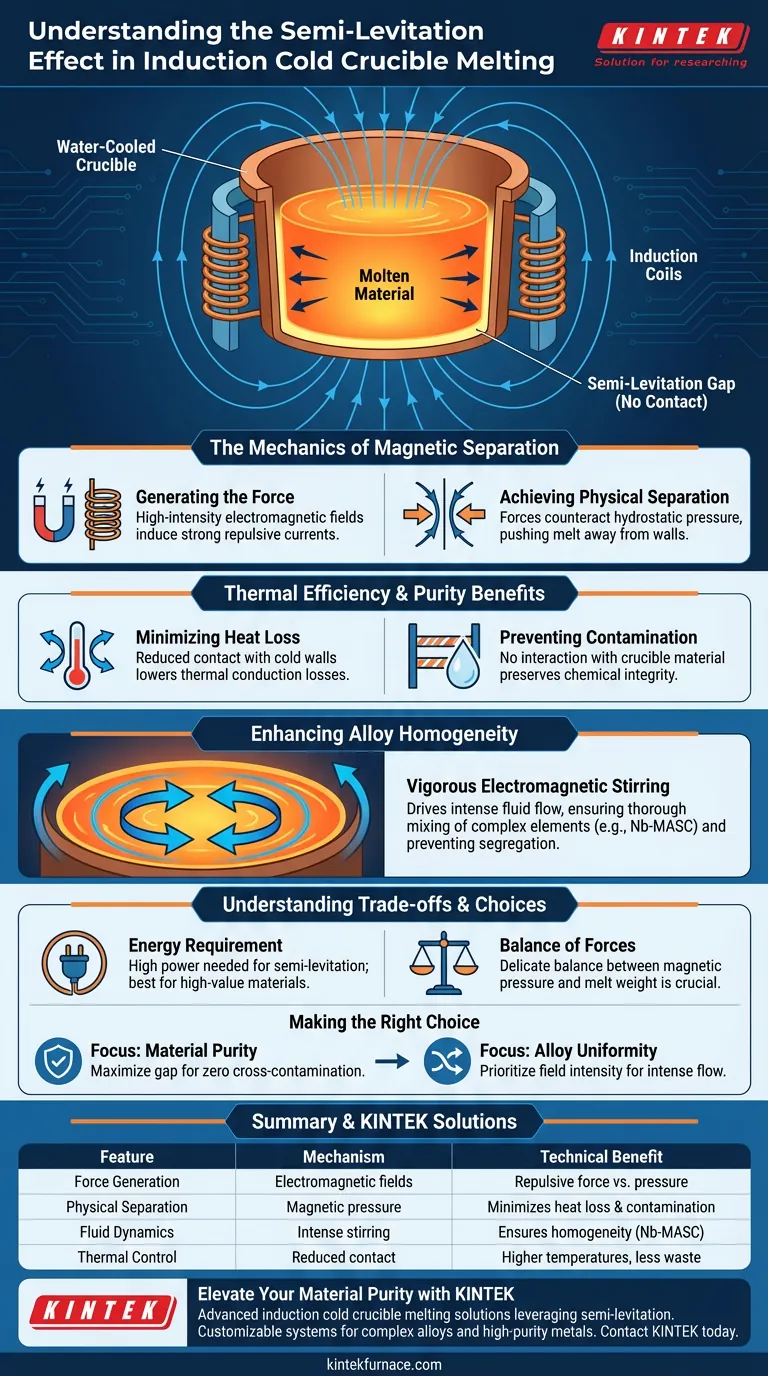

The Mechanics of Magnetic Separation

Generating the Force

The induction cold crucible melting process relies on high-intensity electromagnetic fields. These fields induce currents within the conductive charge that result in strong repulsive forces.

Achieving Physical Separation

These forces counteract the hydrostatic pressure of the liquid metal. As a result, the melt pushes away from the crucible sides, maintaining a "semi-levitated" state rather than resting fully against the container.

Thermal Efficiency and Purity

Minimizing Heat Loss

The crucible walls in this process are water-cooled, which creates a massive temperature differential. By reducing the direct contact area between the melt and these cold walls, the semi-levitation effect significantly lowers thermal conduction losses.

Preventing Contamination

High-temperature melts are often highly reactive and can degrade if they touch the containment vessel. The electromagnetic separation ensures the melt does not interact with the crucible material, preserving the chemical integrity of the alloy.

Enhancing Alloy Homogeneity

Driven Fluid Dynamics

The semi-levitation effect is not static; the same forces that suspend the metal also drive intense fluid flow. This creates a vigorous stirring action within the molten pool that mechanical stirring cannot replicate.

Mixing Complex Elements

This internal agitation is critical for synthesizing materials with complex chemical proportions, such as Nb-MASC alloys. The intense flow ensures that various elemental components are thoroughly mixed, preventing segregation.

Understanding the Trade-offs

The Energy Requirement

Generating the electromagnetic forces necessary for semi-levitation requires substantial power. This is an energy-intensive process designed for high-value materials where standard melting methods fail.

The Balance of Forces

The process relies on a delicate balance between the magnetic pressure and the weight of the melt. If the electromagnetic force is insufficient, the melt will contact the water-cooled wall, leading to rapid heat loss and potential freezing (skull formation).

Making the Right Choice for Your Goal

To maximize the benefits of induction cold crucible melting, align your process parameters with your specific material requirements.

- If your primary focus is material purity: Utilize the semi-levitation effect to maximize the gap between the melt and the wall, ensuring zero cross-contamination from the crucible.

- If your primary focus is alloy uniformity: Prioritize the intensity of the electromagnetic field to drive the fluid flow, ensuring complex elements like those in Nb-MASC are perfectly distributed.

The semi-levitation effect is the critical mechanism that allows modern metallurgy to achieve high temperatures and high purity simultaneously.

Summary Table:

| Feature | Mechanism | Technical Benefit |

|---|---|---|

| Force Generation | High-intensity electromagnetic fields | Creates repulsive force against hydrostatic pressure |

| Physical Separation | Magnetic pressure pushes melt from walls | Minimizes heat loss and prevents crucible contamination |

| Fluid Dynamics | Intense electromagnetic stirring | Ensures chemical homogeneity in complex alloys (e.g., Nb-MASC) |

| Thermal Control | Reduced contact with water-cooled walls | Allows for higher melt temperatures with less energy waste |

Elevate Your Material Purity with KINTEK

Are you struggling with contamination or poor homogeneity in your high-performance alloys? KINTEK’s advanced induction cold crucible melting solutions leverage the power of semi-levitation to provide a barrierless environment for your most reactive materials.

Backed by expert R&D and world-class manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique laboratory and industrial needs. Whether you are synthesizing complex Nb-MASC alloys or refining high-purity metals, our high-temperature furnace expertise ensures consistent, superior results.

Contact KINTEK today to discuss your custom furnace requirements and achieve the ultimate precision in thermal processing.

Visual Guide

References

- M. Guglielmi, Sebastian Herbst. Induction melting in cold crucible furnace for the production of components in turbine applications. DOI: 10.22364/mhd.61.1-2.5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- Why is multiple melting required in a vacuum arc furnace? Achieve Uniform Ni-Mn-Ga Shape Memory Alloys

- Why is induction heating faster than traditional methods? Achieve Instantaneous, Internal Heat Generation

- What are the key application requirements for the vacuum induction furnace? Ensure Safe, High-Purity Metal Processing

- What principle does an induction heater circuit operate on? Discover Efficient, Contactless Heating

- Why are argon (Ar) and sulfur hexafluoride (SF6) introduced during magnesium alloy melting? Protect Your Melt Quality

- What are the components and working principle of a coreless induction furnace? Discover Efficient Metal Melting Solutions

- What types of materials can channel induction furnaces melt? The Ideal High-Volume Metal Melting Solution

- What role does a vacuum induction melting furnace play in the preparation of medium-manganese hull steel?