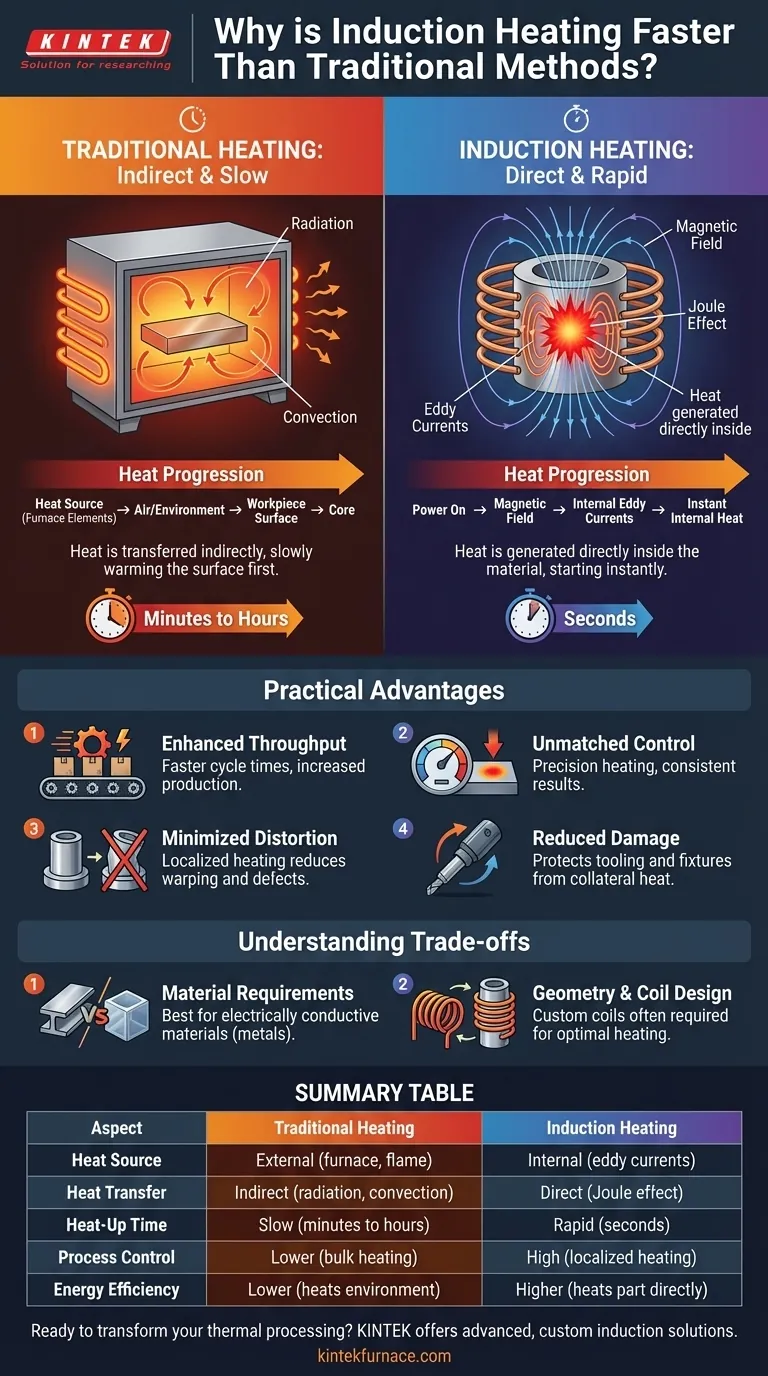

At its core, induction heating is faster because it generates heat directly inside the material you want to heat. Unlike traditional methods that must first heat the surrounding environment and then transfer that heat to the object's surface, induction uses a magnetic field to create internal electrical currents, resulting in instantaneous and targeted heat from within.

The fundamental difference lies in the method of heat delivery. Traditional heating is indirect and slow, relying on convection and radiation. Induction heating is direct and rapid, effectively turning the workpiece into its own heating element.

The Principle: Direct vs. Indirect Energy Transfer

The speed advantage of induction heating is not a minor detail; it is a result of a fundamentally different physical process compared to conventional furnaces.

How Traditional Furnaces Work: Indirect Heating

Traditional methods, such as gas or electric resistance furnaces, operate on the principles of convection and radiation.

First, the furnace's heating elements or burners must heat themselves. They then radiate heat and heat the air or atmosphere inside the furnace (convection). Finally, this hot atmosphere slowly transfers energy to the surface of the workpiece, which then must conduct that heat toward its core. This multi-step process is inherently slow and inefficient, as a significant amount of energy is wasted heating the furnace walls and the air, not just the part.

How Induction Heating Works: Direct Heating

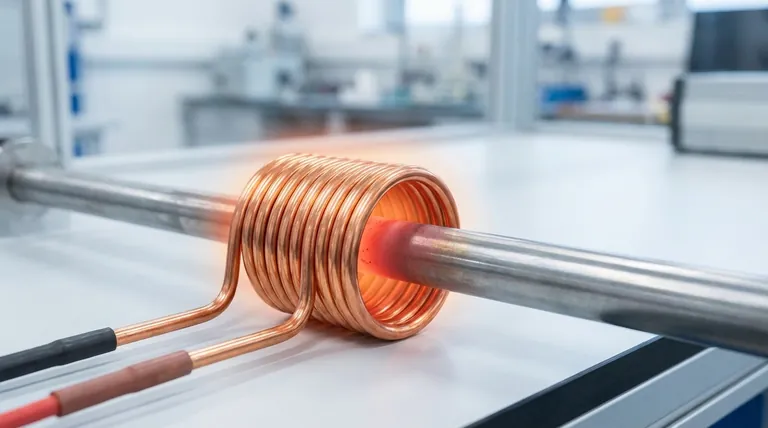

Induction bypasses the slow, indirect transfer of energy. It uses an alternating electric current passed through a copper coil to create a powerful and rapidly changing magnetic field.

When a conductive workpiece (like a piece of steel) is placed within this field, the field induces electrical currents, known as eddy currents, to flow inside the material. The material's natural resistance to the flow of these currents generates intense, immediate heat—a phenomenon known as the Joule effect. Heat is generated inside the part itself, not transferred to it from an external source.

The Immediate Impact on Heat-Up Time

Because heat generation is instantaneous and internal, the time required to bring a material to the desired temperature is drastically reduced. There is no need to wait for a furnace to preheat or for convection to slowly warm a component's surface. The heating begins the moment the power is turned on.

The Practical Advantages of Rapid, Direct Heating

This speed is not just about saving time; it creates a cascade of process improvements that are often more valuable than the time savings alone.

Enhanced Production Throughput

The most obvious benefit is faster cycle times. Processes that might take many minutes or even hours in a furnace can often be completed in seconds with induction, leading to a significant increase in production output.

Unmatched Process Control and Consistency

The magnetic field can be controlled with extreme precision. This allows for very specific areas of a part to be heated without affecting adjacent areas. This localized heating, combined with instant on/off capability, results in superior consistency from one part to the next.

Minimized Part Distortion and Higher Quality

Because the heating is so fast and localized, the rest of the component remains cool. This minimizes the risk of thermal distortion, warping, and other defects that can occur when an entire part is heated slowly. The result is a higher quality end product with less material stress.

Reduced Damage to Tooling and Fixtures

By precisely heating only the target workpiece, induction avoids the collateral heat damage that is common with furnace-based methods. This extends the life of jigs, fixtures, and other machine components that are near the heating zone.

Understanding the Trade-offs

While powerful, induction heating is not a universal solution. Its effectiveness is dependent on specific factors.

Material Requirements

Induction works best with electrically conductive materials, primarily metals. Heating non-conductive materials like plastics or ceramics with induction is not possible without the use of a conductive "susceptor" to act as an intermediary.

Geometry and Coil Design

The efficiency of induction heating is highly dependent on the shape of the induction coil relative to the part. A custom coil is often required to achieve optimal heating for a specific geometry, making it less of a "one size fits all" solution compared to an oven.

Making the Right Choice for Your Goal

To decide if induction is the right fit, you must evaluate it against your primary process objective.

- If your primary focus is high-volume production: Induction's dramatically shorter cycle times provide a direct path to increasing throughput and output.

- If your primary focus is precision and part quality: Induction's localized, controlled heating is unmatched for minimizing distortion and achieving consistent results in applications like hardening or brazing.

- If your primary focus is energy efficiency: Induction's direct heating method wastes very little energy, leading to significantly lower long-term operational costs compared to always-on furnaces.

Understanding the principle of direct, internal heat generation is the key to leveraging induction for faster, more precise, and efficient thermal processing.

Summary Table:

| Aspect | Traditional Heating | Induction Heating |

|---|---|---|

| Heat Source | External (furnace, flame) | Internal (eddy currents) |

| Heat Transfer | Indirect (radiation, convection) | Direct (Joule effect) |

| Heat-Up Time | Slow (minutes to hours) | Rapid (seconds) |

| Process Control | Lower (bulk heating) | High (localized heating) |

| Energy Efficiency | Lower (heats environment) | Higher (heats part directly) |

Ready to transform your thermal processing with the speed and precision of induction heating?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, high-temperature solutions tailored to your unique challenges. Whether your goal is to increase production throughput, enhance part quality, or improve energy efficiency, our team can design a custom induction heating system to meet your exact needs.

Contact us today to discuss how our expertise can accelerate your success.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance