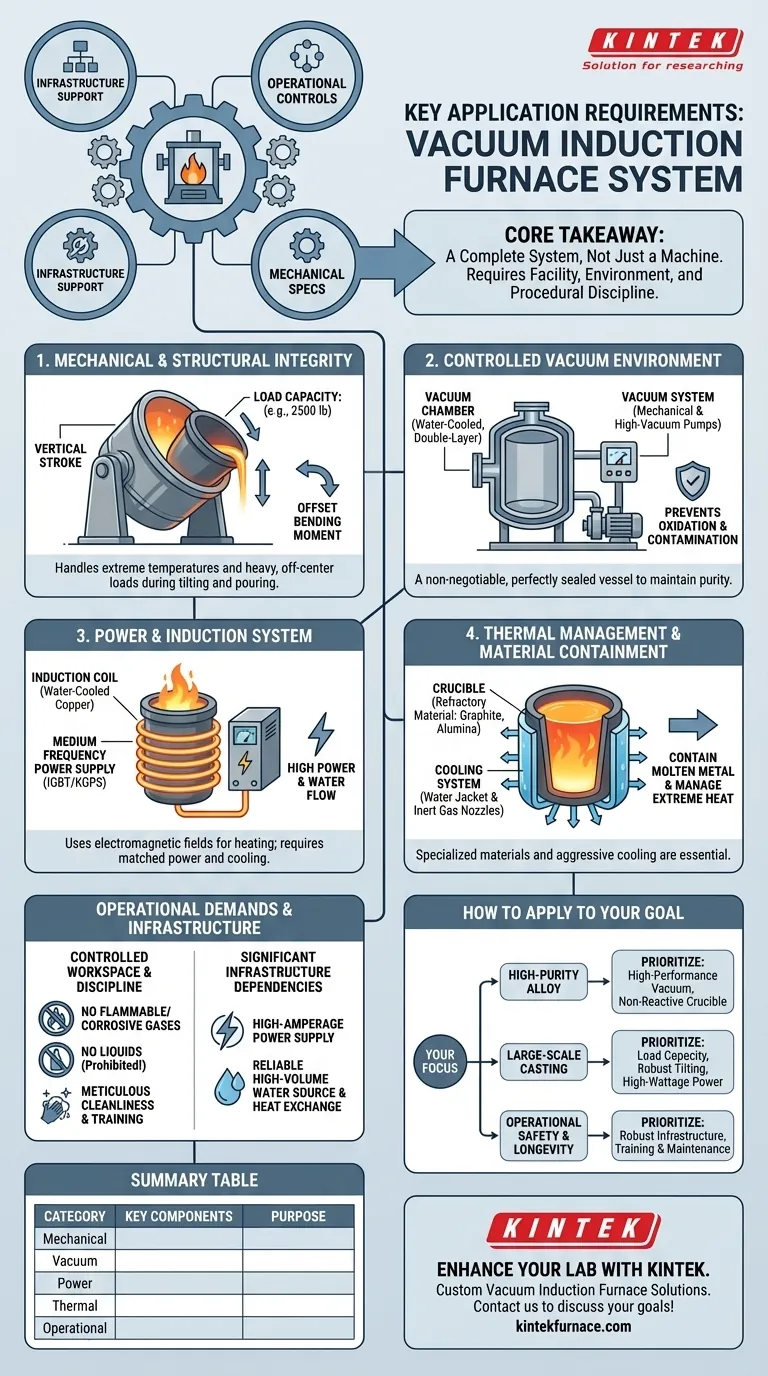

At its core, a vacuum induction furnace has three primary categories of application requirements: mechanical specifications for handling loads, environmental and operational controls to ensure process integrity, and infrastructure support for power and cooling. These requirements ensure the furnace can safely and effectively create a controlled, high-energy environment for processing materials like specialty metals and alloys.

The key takeaway is that a vacuum induction furnace is not a standalone machine but a complete system. Its requirements extend beyond the furnace itself to encompass the facility's infrastructure, the operating environment, and the procedural discipline needed to manage extreme temperatures in a near-perfect vacuum.

Deconstructing the Core Requirements

To properly specify or operate a vacuum induction furnace, you must consider its requirements as an integrated system. Each component's needs directly impact the others, from the physical structure to the power grid it connects to.

1. Mechanical and Structural Integrity

The furnace must be physically capable of handling the materials being processed, often at extreme temperatures. This involves more than just holding a static weight.

For example, a specific application might require a load capacity of 2,500 lb (1,134 kg) and a vertical stroke of 80 inches (2032 mm). This ensures the furnace can lift and manipulate the crucible and its contents.

Critically, the design must also account for a heavy offset bending moment. This occurs when the load is not perfectly centered, especially during tilting and pouring, placing immense stress on the furnace structure and tilting mechanism.

2. The Controlled Vacuum Environment

The defining feature of the furnace is its vacuum. Achieving and maintaining this environment is a non-negotiable requirement.

The vacuum chamber must be a perfectly sealed vessel, often constructed from double-layer, water-cooled steel plates to withstand both atmospheric pressure from the outside and intense heat from the inside.

A robust vacuum system, typically involving a series of mechanical and high-vacuum pumps, is required to remove air and other gases. This prevents oxidation and contamination of the molten metal, which is the primary reason for using a vacuum.

3. Power and Induction System

Unlike a resistance furnace that uses heated elements, an induction furnace uses electromagnetic fields to heat the material. This has specific requirements.

The central component is the induction coil, made from water-cooled copper tubing. It requires a clean, high-flow water source to prevent it from melting.

This coil is energized by a medium frequency power supply (often IGBT or KGPS based). This unit draws a significant amount of electrical power and must be specified to match the heating requirements and melt size of the furnace.

4. Thermal Management and Material Containment

Containing molten metal at thousands of degrees requires specialized materials and aggressive cooling.

The crucible is the vessel that holds the molten metal inside the induction coil. It must be made from a refractory material (like graphite, alumina, or zirconia) that can withstand the target temperature and is non-reactive with the specific alloy being produced.

The furnace body and key components are protected by an extensive cooling system. This typically uses a water jacket and precisely aimed gas nozzles (using inert gases like argon) to cool the material after the heating cycle is complete.

Understanding the Operational Demands

Meeting the technical specifications is only half the battle. The daily operational environment and procedures are just as critical for safety, longevity, and process success.

The Need for a Controlled Workspace

The furnace's surrounding environment is an extension of the system. The working area must be completely free of flammable and corrosive gases that could be drawn into the vacuum system or react with the equipment.

The furnace is not designed to handle liquids or uncontained metals. Direct injection of molten metal or other liquids into the furnace chamber is strictly prohibited, as it can cause explosive vaporization and catastrophic failure.

Strict Operational Discipline

Maintaining the integrity of the vacuum environment is a constant task. The furnace chamber must be kept meticulously clean to prevent outgassing from contaminants, which would spoil the vacuum and ruin the product.

This level of cleanliness and procedural adherence demands well-trained operators who understand the physics of vacuum and high-temperature metallurgy, not just the mechanics of the machine.

Significant Infrastructure Dependencies

A vacuum induction furnace places heavy demands on a facility's infrastructure. The power supply requires high-amperage electrical service, and the extensive water-cooling systems demand a reliable, high-volume water source and heat exchange loop.

These are not minor considerations; they are foundational requirements that must be planned and provisioned for before a furnace can even be installed.

How to Apply This to Your Goal

Your specific application will determine which requirements to prioritize.

- If your primary focus is high-purity alloy production: Prioritize a high-performance vacuum system and the selection of the correct non-reactive crucible material.

- If your primary focus is large-scale casting: Emphasize the mechanical load capacity, a robust tilting mechanism designed for offset moments, and a high-wattage power supply for rapid melting.

- If your primary focus is operational safety and longevity: Focus on installing robust infrastructure for power and cooling, and invest heavily in operator training and strict maintenance protocols.

Understanding these interconnected requirements is the first step toward successfully implementing this powerful technology.

Summary Table:

| Requirement Category | Key Components | Purpose |

|---|---|---|

| Mechanical & Structural | Load capacity, stroke, offset bending moment | Handle materials at high temperatures, ensure safe tilting and pouring |

| Vacuum Environment | Vacuum chamber, vacuum pumps | Prevent oxidation and contamination of molten metals |

| Power & Induction | Induction coil, medium frequency power supply | Generate electromagnetic fields for efficient heating |

| Thermal Management | Crucible, cooling system | Contain molten metal, manage extreme heat with water and gas cooling |

| Operational & Infrastructure | Clean workspace, power supply, cooling water | Maintain safety, support daily operations with reliable utilities |

Ready to enhance your laboratory's capabilities with a custom vacuum induction furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet unique experimental requirements. Whether you're focused on high-purity alloy production, large-scale casting, or operational safety, we deliver reliable, efficient systems. Contact us today to discuss how we can support your goals and bring precision to your processes!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries