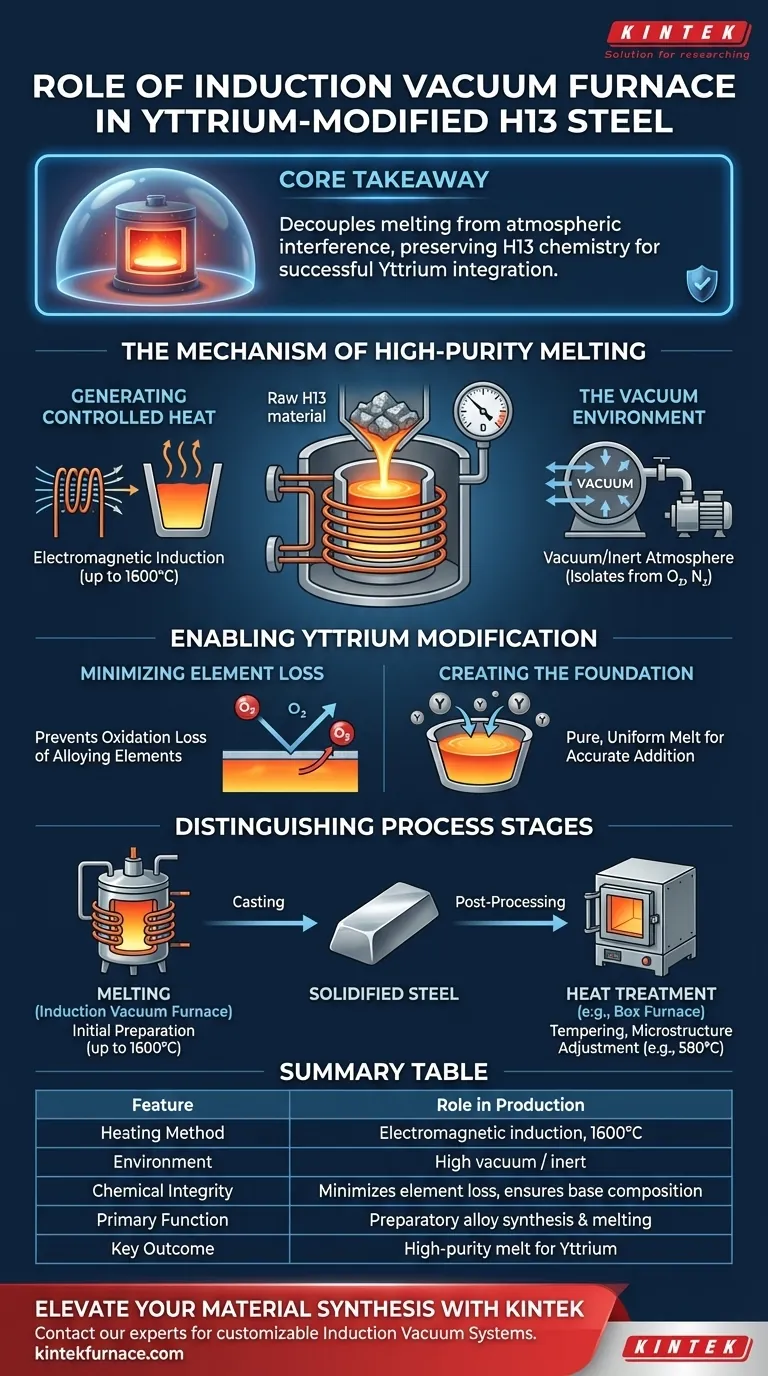

The induction vacuum furnace acts as the critical preparatory vessel for creating high-quality Yttrium-modified H13 steel. It utilizes electromagnetic induction to generate extreme heat (up to 1600°C) within a controlled vacuum or inert atmosphere, ensuring the base material is melted without atmospheric contamination. This specific environment is required to minimize the oxidation loss of alloying elements, creating a pure, uniform melt that serves as the necessary foundation for the precise addition of rare earth elements like Yttrium.

Core Takeaway The primary function of the induction vacuum furnace is to decouple the melting process from atmospheric interference. By eliminating oxidation, it preserves the precise chemical composition of H13 steel, enabling the successful integration of reactive rare earth elements like Yttrium into the alloy matrix.

The Mechanism of High-Purity Melting

Generating Controlled Heat

The furnace employs electromagnetic induction as its primary heat source.

This technology allows for rapid and precise temperature escalation, capable of reaching and maintaining the 1600 degrees Celsius required to fully melt raw H13 steel materials.

The Vacuum Environment

The defining feature of this equipment is the vacuum chamber, which houses both the induction coil and the charge (the material being melted).

By operating under a vacuum or an inert atmosphere, the furnace isolates the molten steel from oxygen and nitrogen in the air.

Enabling Yttrium Modification

Minimizing Element Loss

Standard atmospheric melting often leads to the oxidation loss of critical alloying elements.

The induction vacuum furnace effectively minimizes this loss, ensuring that the base chemistry of the H13 steel remains intact before modification.

Creating the Foundation for Alloying

Yttrium is a rare earth element that requires a stable, high-purity environment to be effective.

By ensuring the molten steel has a highly pure and uniform composition, the furnace provides the necessary baseline for the accurate addition of Yttrium.

Without this controlled environment, the introduction of rare earth elements would be inconsistent and chemically compromised.

Distinguishing Process Stages

Melting vs. Heat Treatment

It is vital to distinguish between the melting phase and subsequent heat treatment phases.

The induction vacuum furnace is responsible solely for the melting and initial preparation of the alloy.

The Role of Post-Processing

Once the steel is cast, other equipment takes over to modify the microstructure.

For example, a laboratory high-temperature box furnace is used later to temper the steel at lower temperatures (e.g., 580°C) to facilitate carbide precipitation and manage carbon segregation at grain boundaries.

The induction furnace does not perform this tempering function; it simply creates the high-quality raw material that makes successful tempering possible.

Making the Right Choice for Your Goal

- If your primary focus is alloy synthesis: Rely on the induction vacuum furnace to melt the steel and protect the chemical integrity of reactive additions like Yttrium.

- If your primary focus is microstructural adjustment: Utilize a high-temperature box furnace to perform tempering and drive the redistribution of alloying elements after the steel has solidified.

Success in producing Yttrium-modified H13 steel requires using the induction vacuum furnace to guarantee the purity of the melt before any thermal processing begins.

Summary Table:

| Feature | Role in Yttrium-Modified H13 Production |

|---|---|

| Heating Method | Electromagnetic induction reaching up to 1600°C for rapid, uniform melting. |

| Environment | High vacuum or inert atmosphere to prevent oxidation of reactive rare earth elements. |

| Chemical Integrity | Minimizes alloying element loss, ensuring a precise and consistent base composition. |

| Primary Function | Preparatory alloy synthesis and melting (distinct from post-cast heat treatment). |

| Key Outcome | Creation of a high-purity melt necessary for effective Yttrium integration. |

Elevate Your Material Synthesis with KINTEK

Precise alloy modification like Yttrium-integration requires uncompromising control over the melting environment. KINTEK provides industry-leading Induction Vacuum Systems, Muffle, Tube, and CVD furnaces designed to meet the rigorous demands of advanced metallurgy.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to your unique research or production needs. Whether you are synthesizing new alloys or refining microstructures, KINTEK offers the thermal precision your project deserves.

Ready to optimize your high-temperature processes? Contact our experts today to find the perfect customized solution for your laboratory.

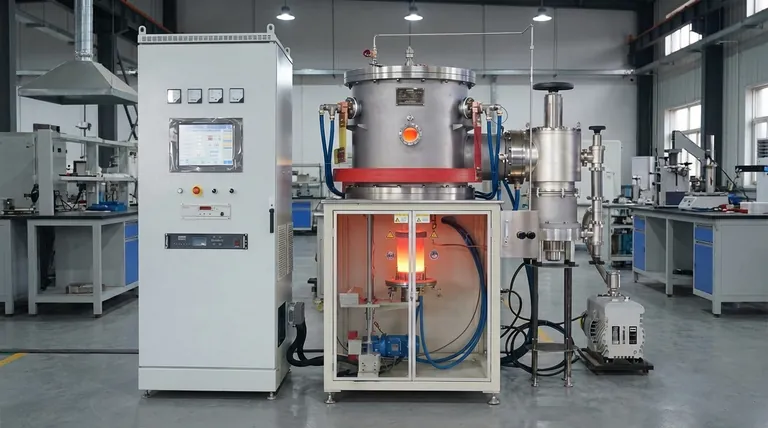

Visual Guide

References

- Y. Q. Wang, Bin Yang. Improved Corrosion Resistance of Yttrium-Bearing H13 Steel for Shield Machine Cutter Ring. DOI: 10.3390/met15090935

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why are crucible furnaces important in industrial applications? Versatile, Cost-Effective Melting Solutions

- What role does the induction coil play in an induction melting furnace? It's the Engine of Efficient Melting

- How does an induction furnace heat metal? Achieve Fast, Clean, and Precise Metal Melting

- Why is a high-purity argon environment required during iron melting? Ensure Precise Steel Oxide Inclusion Simulation

- What industries and applications use Vacuum Induction Melting Furnaces? Essential for High-Purity Materials

- How does an integrated system of in-situ neutron diffraction, high-frequency induction heating, and deformation devices address technical challenges in metallurgical research? Uncover Real-Time Microstructural Evolution

- What role does a vacuum induction melting furnace play in the modification of W18Cr4V steel? Enhance Alloy Purity

- Why are argon (Ar) and sulfur hexafluoride (SF6) introduced during magnesium alloy melting? Protect Your Melt Quality