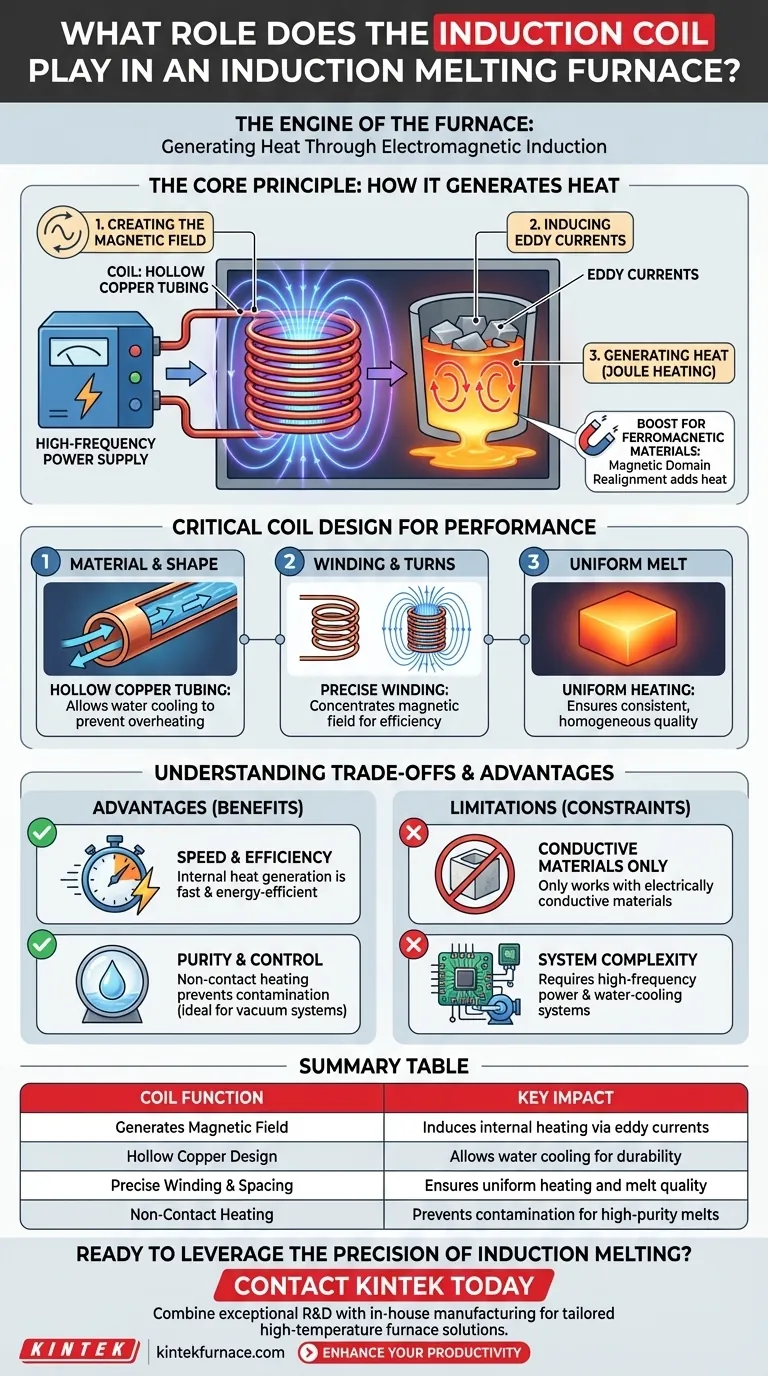

At its core, the induction coil is the engine of the furnace. It is a precisely wound copper tube that generates a powerful magnetic field to heat and melt conductive materials. It accomplishes this without any direct physical contact, transferring energy through the principle of electromagnetic induction.

The induction coil's fundamental role is not to get hot itself, but to create a concentrated, fluctuating magnetic field. This field induces electrical currents directly within the metal charge, turning the material into its own heat source for rapid, clean, and highly controlled melting.

The Core Principle: How the Coil Generates Heat

The coil's function is a direct application of Faraday's Law of Induction. The process can be broken down into a few distinct steps that happen almost instantaneously.

Step 1: Creating the Magnetic Field

A high-frequency alternating current (AC) is passed through the copper induction coil. Because the current is constantly and rapidly changing direction, it generates an equally dynamic and powerful magnetic field in the space within and around the coil.

Step 2: Inducing Eddy Currents

When a conductive material, such as metal scrap or ingots, is placed inside the crucible surrounded by the coil, this fluctuating magnetic field passes through it. The field induces small, circular electrical currents within the metal itself. These are known as eddy currents.

Step 3: Generating Heat Through Resistance

The induced eddy currents are not unopposed. The metal's own natural electrical resistance works against the flow of these currents, generating immense friction and, consequently, intense heat. This phenomenon is known as Joule heating, and it is what causes the material's temperature to rise rapidly.

An Added Boost for Ferromagnetic Metals

For materials like iron, steel, or nickel (known as ferromagnetic materials), an additional heating effect occurs. The rapidly changing magnetic field forces the magnetic domains within the metal to realign constantly, which generates further heat and contributes to an even faster melting process.

Why Coil Design is Critical for Performance

The coil is not just a simple loop of wire; it is a highly engineered component where every detail impacts the furnace's efficiency and the quality of the final product.

The Material and Shape

Induction coils are almost always made from high-conductivity hollow copper tubing. Copper offers minimal electrical resistance, and the hollow design allows cooling water to be circulated through it, preventing the coil itself from overheating and melting.

Winding and Turns

The number of turns in the coil and the spacing between them are calculated to shape and concentrate the magnetic field. A tightly wound coil creates a more intense field, focusing energy for maximum efficiency and ensuring it couples effectively with the metal charge.

Ensuring a Uniform Melt

A properly designed coil generates a uniform magnetic field, which in turn promotes even heating throughout the metal. This prevents hot spots and ensures a consistent, homogenous melt, which is critical for producing high-quality alloys.

Understanding the Trade-offs and Advantages

The induction coil is the source of the technology's primary benefits but also defines its limitations.

Advantage: Speed and Efficiency

Because heat is generated inside the material, melting is extremely fast. Very little energy is wasted heating the furnace chamber or the surrounding air, making the process highly energy-efficient compared to fuel-fired methods.

Advantage: Purity and Control

The non-contact nature of induction heating means the melt is not contaminated by combustion byproducts or electrode materials. This is essential for producing high-purity metals and alloys. This advantage is maximized in systems like vacuum induction furnaces, where melting in a vacuum prevents oxidation.

Limitation: Conductive Materials Only

The entire principle relies on inducing electrical currents. Therefore, this method can only be used to heat or melt electrically conductive materials. Non-conductive materials like ceramics or dry refractories will not heat up in an induction field.

Limitation: System Complexity

An induction furnace requires a sophisticated high-frequency power supply to drive the coil and a robust water-cooling system to protect it. This makes the initial setup more complex and costly than some simpler furnace types.

Making the Right Choice for Your Goal

Understanding the coil's function allows you to leverage the technology to meet specific operational targets.

- If your primary focus is process efficiency: Recognize that the coil's design and its coupling with the power supply are the most critical factors in controlling energy consumption and melt times.

- If your primary focus is material purity: The induction coil's non-contact heating method is your greatest asset, as it inherently prevents the contamination common in fuel-fired or arc furnaces.

- If your primary focus is precise temperature control: The coil, paired with its power supply, allows for immediate and accurate adjustments to the heat being generated directly within the metal.

By mastering the principles of the induction coil, you gain direct control over the quality, speed, and efficiency of your melting operation.

Summary Table:

| Coil Function | Key Impact |

|---|---|

| Generates Magnetic Field | Induces internal heating via eddy currents |

| Hollow Copper Design | Allows water cooling for durability |

| Precise Winding & Spacing | Ensures uniform heating and melt quality |

| Non-Contact Heating | Prevents contamination for high-purity melts |

Ready to leverage the precision of induction melting for your operation?

At KINTEK, we combine exceptional R&D with in-house manufacturing to deliver advanced high-temperature furnace solutions. Our expertise in induction technology ensures you get a system perfectly tailored to your needs—whether you're focused on ultimate material purity, maximum energy efficiency, or precise process control.

Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique requirements.

Contact our experts today to discuss how our induction melting solutions can enhance your productivity and product quality.

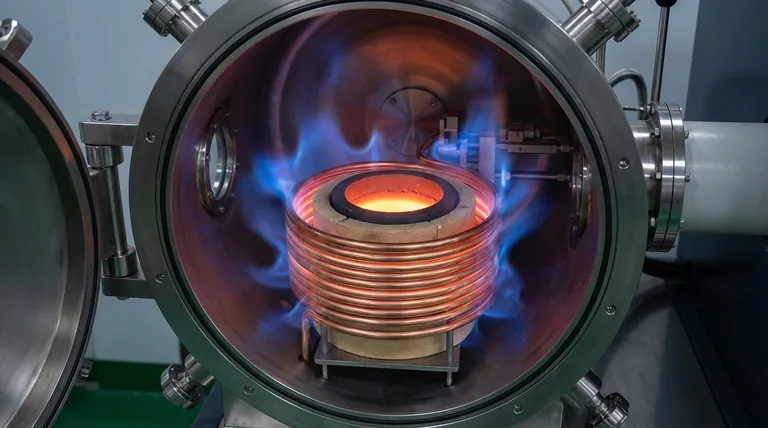

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab