In short, Vacuum Induction Melting (VIM) furnaces are indispensable in high-stakes industries like aerospace, energy, medical, and electronics. Their use is centered on applications where material purity and performance are absolutely critical, such as creating superalloys for jet engine components, manufacturing high-purity metals for medical implants, and producing specialized materials for semiconductors.

The core value of a VIM furnace isn't just melting metal; it's about creating a controlled, contamination-free environment. By removing air and other gases, the vacuum process allows for the production of exceptionally pure, strong, and reliable materials that would be impossible to create using conventional melting techniques.

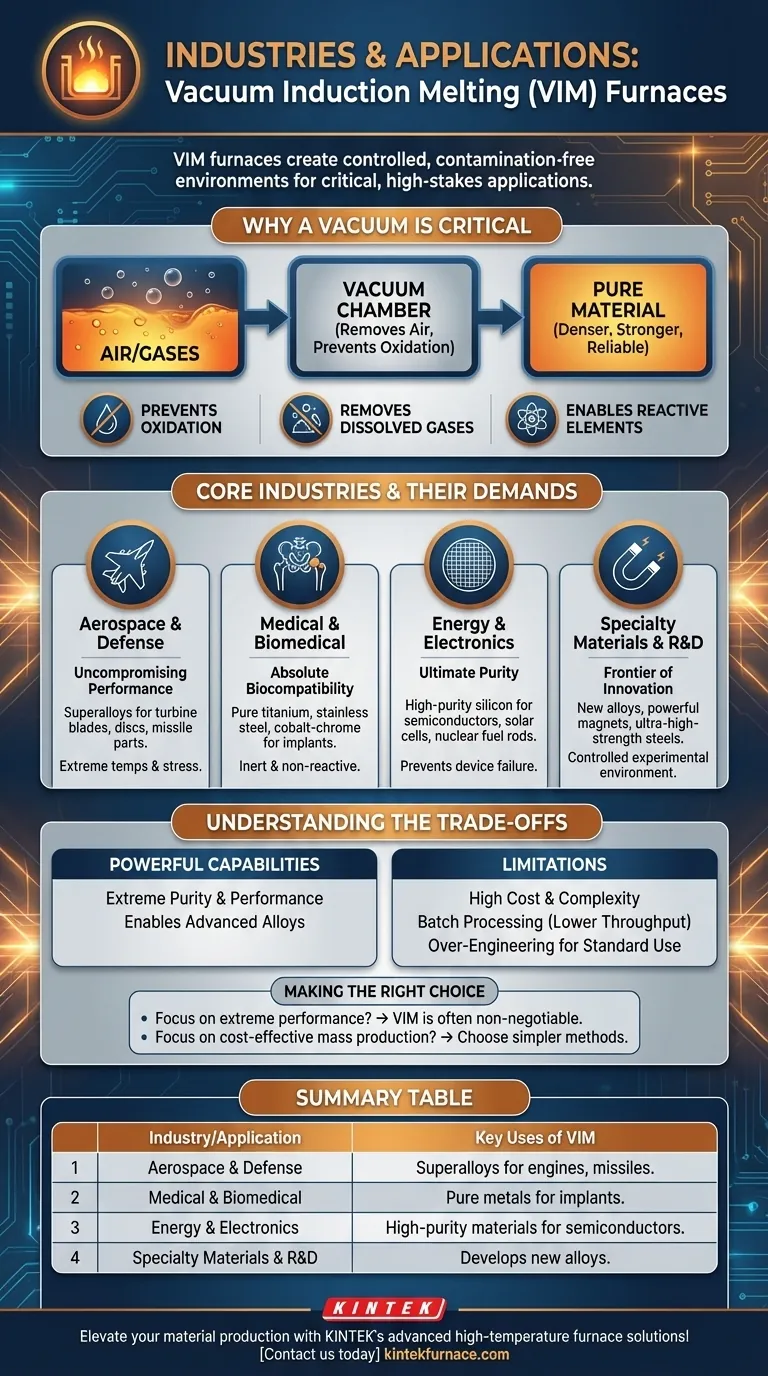

Why a Vacuum is the Critical Factor

The decision to use a VIM furnace is driven by the need to control a material's chemistry with extreme precision. The vacuum environment is the key to achieving this.

Preventing Oxidation and Contamination

At the high temperatures required for melting, most metals will readily react with oxygen and nitrogen in the atmosphere. This reaction, called oxidation, introduces impurities that degrade the material's strength, ductility, and overall performance.

A VIM furnace removes the air, eliminating this threat and ensuring the final product is chemically pure and free from oxide inclusions.

Removing Dissolved Gases

Molten metal can hold dissolved gases like oxygen, hydrogen, and nitrogen. As the metal cools and solidifies, these gases can get trapped, forming microscopic pores and voids.

This internal porosity acts as a structural defect, significantly weakening the material. The vacuum actively pulls these dissolved gases out of the molten bath, resulting in a denser, more robust final casting.

Enabling the Use of Reactive Elements

Many advanced superalloys rely on reactive elements like titanium, aluminum, and niobium to achieve their exceptional high-temperature strength.

When melted in the presence of air, these valuable elements would simply burn off and be lost as oxide dross. The vacuum protects them, ensuring they remain in the alloy to deliver their intended properties.

Core Industries and Their Demands

The unique capabilities of VIM furnaces make them essential for sectors where material failure is not an option.

Aerospace and Defense: Uncompromising Performance

This is the largest user of VIM technology. It is used to produce the nickel-based and cobalt-based superalloys required for jet engine turbine blades, discs, and other components that must withstand extreme temperatures and stress.

Applications include aircraft parts, missile and rocket components, and satellite systems where strength-to-weight ratio and reliability are paramount.

Medical and Biomedical: Absolute Biocompatibility

The human body is highly sensitive to impurities. VIM is used to produce extremely pure titanium, stainless steels, and cobalt-chrome alloys for medical implants like hip joints, dental implants, and pacemakers.

The process ensures the final material is inert, non-reactive, and free from contaminants that could cause an adverse reaction in a patient.

Energy and Electronics: Ultimate Purity

In the nuclear industry, VIM is used to create materials for fuel rods. In electronics and power generation, it is essential for producing the high-purity silicon for semiconductors and specialized alloys for solar cells.

In these applications, even infinitesimal impurities can drastically alter electrical properties and cause device failure, making VIM a necessity.

Specialty Materials and R&D: The Frontier of Innovation

VIM furnaces are a cornerstone of materials science. They are used to develop new high-temperature alloys, create powerful permanent magnet materials, and refine ultra-high-strength steels.

Researchers use VIM to experiment with novel alloy compositions in a perfectly controlled environment, pushing the boundaries of material performance.

Understanding the Trade-offs

While powerful, VIM technology is not the solution for every melting application. Understanding its limitations is key to making an informed decision.

High Cost and Complexity

VIM furnaces are significantly more expensive to purchase, operate, and maintain than standard air-melting furnaces. The need for robust vacuum pumps, sophisticated controls, and longer processing times adds to the overall cost per part.

Batch Processing and Throughput

Most VIM operations are batch processes, where one specific quantity of metal is melted at a time. This is less suited for high-volume, continuous production compared to other melting methods, potentially limiting throughput.

Over-Engineering for Standard Applications

For many common applications, such as structural steel for construction or standard cast iron parts, the exceptional purity offered by VIM is unnecessary. The added cost provides no functional benefit, making simpler, more economical melting techniques the logical choice.

Making the Right Choice for Your Application

Selecting the right melting process depends entirely on the performance requirements of your final product.

- If your primary focus is extreme performance and reliability (aerospace, defense, medical): VIM is often non-negotiable for creating the required superalloys and pure metals that can withstand harsh environments.

- If your primary focus is producing high-purity electronic or magnetic materials: VIM is the essential tool for eliminating the chemical impurities that would otherwise degrade critical electrical and magnetic properties.

- If your primary focus is cost-effective mass production of standard alloys: Simpler and faster air-melting or argon-oxygen decarburization (AOD) processes are almost always the more appropriate and economical choice.

Ultimately, vacuum induction melting is the definitive solution for applications where material integrity cannot be compromised.

Summary Table:

| Industry/Application | Key Uses of VIM Furnaces |

|---|---|

| Aerospace & Defense | Produces superalloys for jet engines, missiles, and satellites |

| Medical & Biomedical | Creates pure metals for implants like hip joints and pacemakers |

| Energy & Electronics | Manufactures high-purity silicon for semiconductors and nuclear materials |

| Specialty Materials & R&D | Develops new alloys and high-strength materials in controlled environments |

Elevate your material production with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable options like Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, and more. Our strong deep customization capability ensures we precisely meet your unique experimental needs for achieving superior purity and performance in critical applications. Contact us today to discuss how we can support your industry-specific challenges!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries