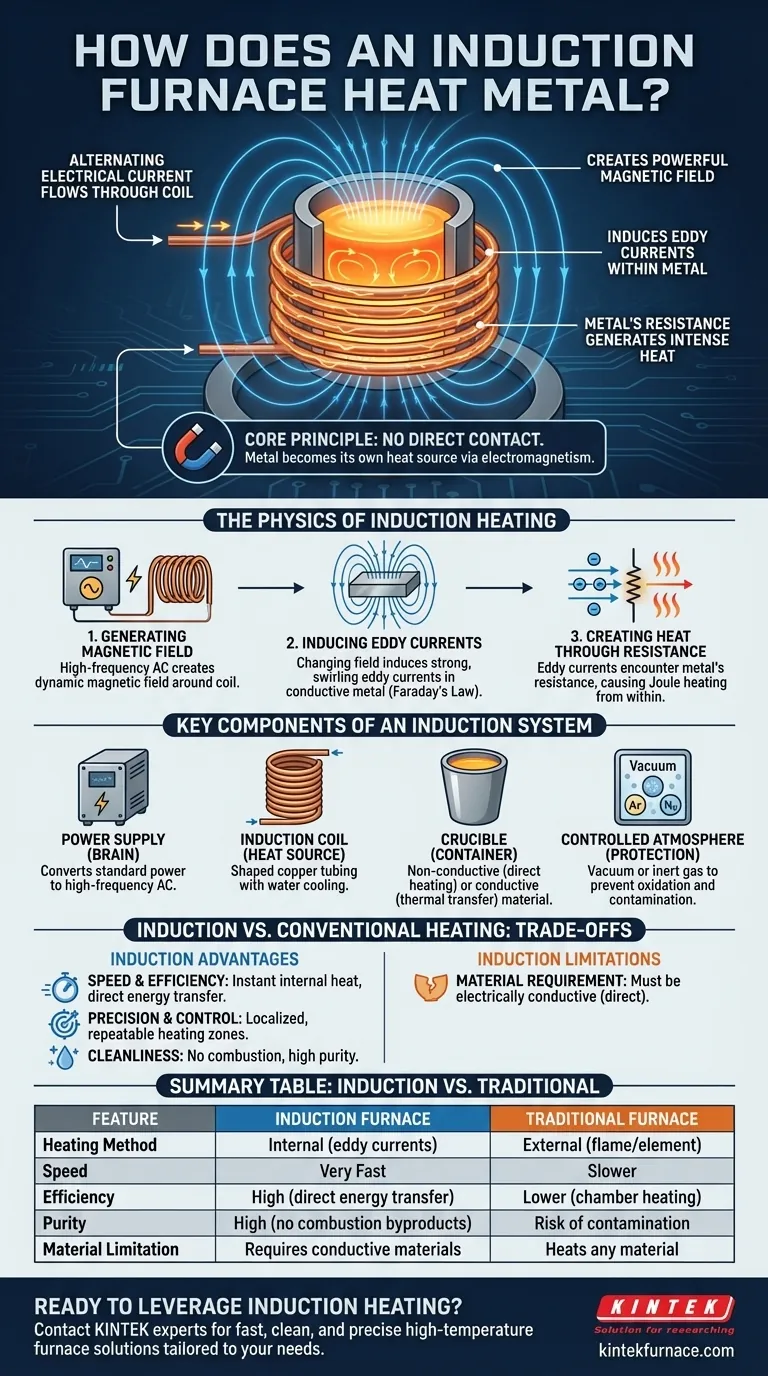

At its core, an induction furnace heats metal without any direct contact or flame. It uses the principles of electromagnetism to turn the metal itself into the source of heat. An alternating electrical current flows through a copper coil, creating a powerful and rapidly changing magnetic field. This field induces strong internal electrical currents—called eddy currents—within the metal. The metal’s natural resistance to the flow of these currents generates intense, precise heat, melting it from within.

Unlike traditional furnaces that heat a material from the outside, an induction furnace uses a magnetic field to make the metal generate its own heat. This fundamental difference is the key to its speed, precision, and efficiency.

The Physics of Induction Heating

To truly grasp how an induction furnace works, it's helpful to break the process down into three distinct physical steps. Each step builds on the last, culminating in the rapid melting of conductive materials.

Step 1: Generating the Magnetic Field

The process begins with a specialized power supply that sends a high-frequency alternating current (AC) to an induction coil, which is typically made of copper. As this current rapidly switches direction, it generates a powerful and dynamic magnetic field in and around the coil, following the principles of electromagnetism.

Step 2: Inducing Eddy Currents

When a conductive material like metal is placed within this magnetic field, the field lines pass through it. According to Faraday's Law of Induction, a changing magnetic field induces a voltage in any conductor it passes through. This induced voltage creates strong, swirling electrical currents within the metal, known as eddy currents.

You can think of this as a transformer relationship: the furnace coil is the primary winding, and the piece of metal acts as a single-turn secondary winding that is short-circuited on itself.

Step 3: Creating Heat Through Resistance

All metals have some level of electrical resistance. As the powerful eddy currents flow through the metal, they encounter this resistance, which causes intense heat to be generated. This phenomenon, known as Joule heating, is what melts the metal. The heat is generated directly within the material, making the process incredibly fast and efficient.

Key Components of an Induction System

An induction furnace is more than just a coil. It is a system of components working together to control the heating process with high precision.

The Power Supply

This is the brain of the operation. It takes standard electrical power and converts it into the high-frequency alternating current required by the induction coil. The frequency is a critical control parameter that influences the depth and intensity of the heating.

The Induction Coil

Usually constructed from hollow copper tubing, the coil is shaped to optimize the magnetic field for the specific application. Water is constantly circulated through the hollow tubing to keep the coil itself from overheating, as it is in close proximity to the intense heat it is creating.

The Crucible

This is the container that holds the metal charge. The crucible material is a critical choice.

- Non-conductive crucibles (e.g., ceramics) are transparent to the magnetic field, which passes through them to heat the metal directly. This is ideal for ensuring purity.

- Conductive crucibles (e.g., graphite) are heated by the magnetic field along with the charge inside. This can be useful for heating non-conductive materials via thermal transfer from the crucible.

The Controlled Atmosphere

Many induction furnaces are designed to operate under a specific atmosphere to protect the metal. This can include a vacuum to remove all reactive gases or an inert gas blanket (like Argon or Nitrogen) to prevent oxidation and contamination during melting.

Understanding the Trade-offs: Induction vs. Conventional Heating

The choice of a heating method depends entirely on the goal. Induction offers unique advantages but also has specific limitations compared to traditional methods like fuel-fired or resistive muffle furnaces.

Advantage: Speed and Efficiency

Because heat is generated inside the workpiece, the process is extremely fast. There is no need to wait for a chamber to heat up and then slowly transfer that heat to the material. This direct energy transfer also results in higher overall energy efficiency.

Advantage: Precision and Control

The magnetic field can be precisely controlled, allowing for localized and repeatable heating. Unlike a muffle furnace that heats its entire interior, an induction system can target a specific zone, which is critical for applications like surface hardening.

Advantage: Cleanliness

Induction heating is a perfectly clean process. There is no combustion, which means no byproducts to contaminate the metal. This makes it the superior choice for producing high-purity medical or aerospace alloys.

Limitation: Material Requirement

The greatest limitation of induction is that it only works directly on electrically conductive materials. To heat materials like ceramics or certain polymers, you must first heat a conductive crucible and then rely on thermal conduction, which negates some of the speed advantage.

Making the Right Choice for Your Goal

Selecting the right furnace technology requires aligning its capabilities with your primary objective.

- If your primary focus is speed and high-volume production: Induction heating is superior due to its nearly instantaneous heating cycles.

- If your primary focus is metallurgical purity and alloy quality: The clean, controlled atmosphere of an induction furnace is essential for preventing contamination.

- If your primary focus is energy efficiency and process control: Induction is generally more efficient, as it delivers energy directly into the workpiece with minimal wasted heat.

- If your primary focus is simply heating non-conductive materials: A conventional resistive furnace is often a more straightforward and cost-effective solution.

By understanding that induction heating makes the material its own heat source, you can leverage this unique technology for cleaner, faster, and more precise material processing.

Summary Table:

| Feature | Induction Furnace | Traditional Furnace |

|---|---|---|

| Heating Method | Internal (eddy currents) | External (flame/element) |

| Speed | Very Fast | Slower |

| Efficiency | High (direct energy transfer) | Lower (chamber heating) |

| Purity | High (no combustion byproducts) | Risk of contamination |

| Material Limitation | Requires conductive materials | Heats any material |

Ready to leverage the speed and purity of induction heating for your lab?

At KINTEK, we combine exceptional R&D with in-house manufacturing to deliver advanced high-temperature furnace solutions. Our induction furnaces are designed for laboratories that demand fast, clean, and precise metal melting for high-purity alloys and high-volume production.

Contact our experts today to discuss how our induction furnace solutions can be customized to meet your unique experimental and production requirements.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries