At its core, the vacuum chamber in a casting furnace functions as a sealed enclosure where air and other atmospheric gases are pumped out to create an ultra-low-pressure environment. This vacuum acts as a protective shield, preventing the molten metal from reacting with oxygen and other gases, which would otherwise introduce impurities and compromise the final product's quality.

The vacuum chamber is not merely a container; it is an active system designed to create a chemically pure environment. Its primary purpose is to eliminate atmospheric interference, ensuring the molten metal's integrity from the moment it melts to the moment it solidifies.

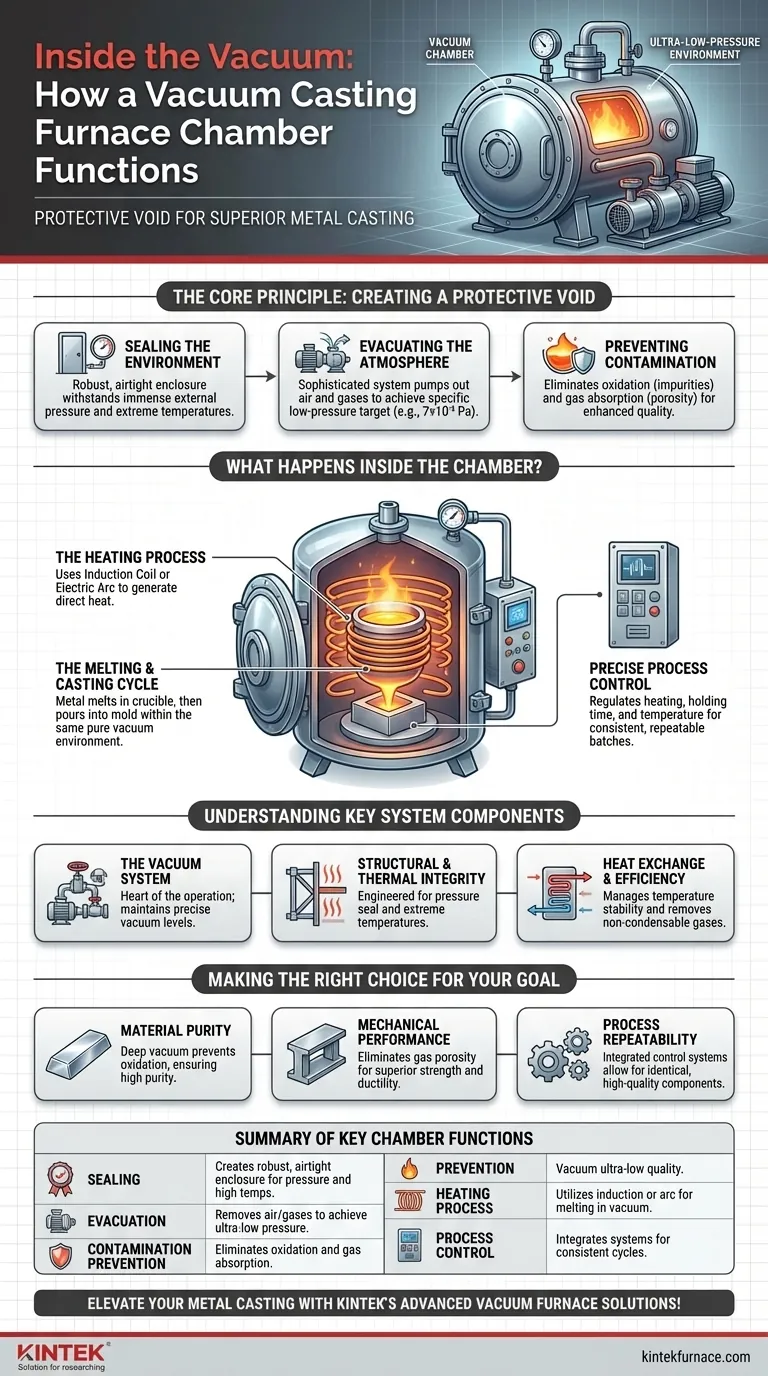

The Core Principle: Creating a Protective Void

The entire process hinges on the chamber's ability to create and maintain a stable vacuum. This seemingly simple concept is critical for producing high-performance metal components.

Sealing the Environment

A vacuum casting furnace chamber is a robust, sealed enclosure. It is engineered to withstand immense external pressure from the atmosphere once the internal air is evacuated, as well as the extreme temperatures generated during the melting process.

Evacuating the Atmosphere

A sophisticated vacuum system, consisting of powerful pumps, valves, and gauges, is connected to the chamber. This system actively removes air and other gases to achieve a specific, low-pressure target, often measured in Pascals (Pa).

Preventing Contamination

Removing the atmosphere is crucial for two reasons:

- Preventing Oxidation: Without a vacuum, the hot, reactive molten metal would instantly bond with oxygen in the air. This creates oxides (impurities) that can weaken the final casting.

- Eliminating Gas Absorption: Gases like hydrogen and nitrogen can dissolve into the molten metal and then form tiny bubbles or pores as the metal cools. This gas porosity creates internal weak points, drastically reducing the material's strength and ductility.

What Happens Inside the Chamber?

The chamber is where the critical stages of melting and casting take place. It houses all the necessary components in a controlled environment.

The Heating Process

The chamber contains a heating source to melt the raw metal (the charge). Common methods include an induction coil, which uses electromagnetic fields to generate heat directly within the metal, or an electric arc, which melts the material with a high-energy electrical discharge.

The Melting and Casting Cycle

The raw metal charge is placed inside a crucible, which is then enclosed within the vacuum chamber. Once the vacuum is established, the heating system is activated. After the metal reaches the desired temperature, it is poured into a mold, often also located within the same vacuum environment to maintain purity.

Precise Process Control

A temperature control system works alongside the vacuum system. It precisely regulates the heating speed, holding time, and overall temperature to ensure the melting process is consistent and repeatable, batch after batch.

Understanding the Key System Components

The effectiveness of the vacuum chamber depends on the integration of several critical subsystems. Mismanagement of any part can compromise the entire process.

The Vacuum System

This is the heart of the operation. It includes pumps to create the vacuum, valves to isolate the chamber, and gauges to monitor the pressure level. Maintaining a specific vacuum level (e.g., as low as 7×10⁻³ Pa) is essential for ensuring the purity of highly reactive alloys.

Structural and Thermal Integrity

The chamber itself must be a feat of engineering. It has to maintain a perfect seal under a pressure differential of one entire atmosphere while simultaneously containing a process running at hundreds or thousands of degrees Celsius.

Heat Exchange and Efficiency

Advanced furnaces incorporate heat exchange systems to manage the extreme temperatures. These systems, sometimes using a medium like water in a separate jacket, help maintain thermal stability. They also improve efficiency by removing non-condensable gases that could otherwise hinder heat transfer within the chamber.

Making the Right Choice for Your Goal

The function of the vacuum chamber directly enables specific quality outcomes. Understanding this link helps you focus on the most critical process parameters.

- If your primary focus is material purity: The ability of the vacuum system to achieve and hold a deep vacuum is the most critical factor for preventing oxidation.

- If your primary focus is mechanical performance: The elimination of gas porosity, guaranteed by removing the atmosphere before melting, is essential for achieving superior strength and ductility.

- If your primary focus is process repeatability: The integrated temperature and vacuum control systems are what allow you to produce identical, high-quality components every time.

Ultimately, the vacuum chamber transforms casting from a simple melting process into a precise science of material creation.

Summary Table:

| Aspect | Function |

|---|---|

| Sealing | Creates a robust, airtight enclosure to withstand pressure and high temperatures. |

| Evacuation | Removes air and gases using pumps and valves to achieve ultra-low pressure (e.g., 7×10⁻³ Pa). |

| Contamination Prevention | Eliminates oxidation and gas absorption, reducing impurities and porosity in the final product. |

| Heating Process | Utilizes induction coils or electric arcs to melt metal within the vacuum environment. |

| Process Control | Integrates temperature and vacuum systems for consistent, repeatable melting and casting cycles. |

Elevate your metal casting with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, delivering superior purity, mechanical performance, and process repeatability. Contact us today to discuss how our tailored solutions can optimize your results!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys