Vacuum Induction Melting (VIM) is a sophisticated metallurgical process that uses electromagnetic induction to melt metals and alloys within a high-vacuum chamber. This combination of contactless heating and a controlled atmosphere allows for the production of materials with exceptional purity, precise chemical composition, and superior mechanical properties, free from the contamination that occurs when melting in open air.

The core advantage of VIM is not just one technology, but the synergy of two: contactless induction heating provides clean, efficient melting, while the vacuum environment actively removes impurities and prevents oxidation, resulting in a level of quality unattainable by conventional methods.

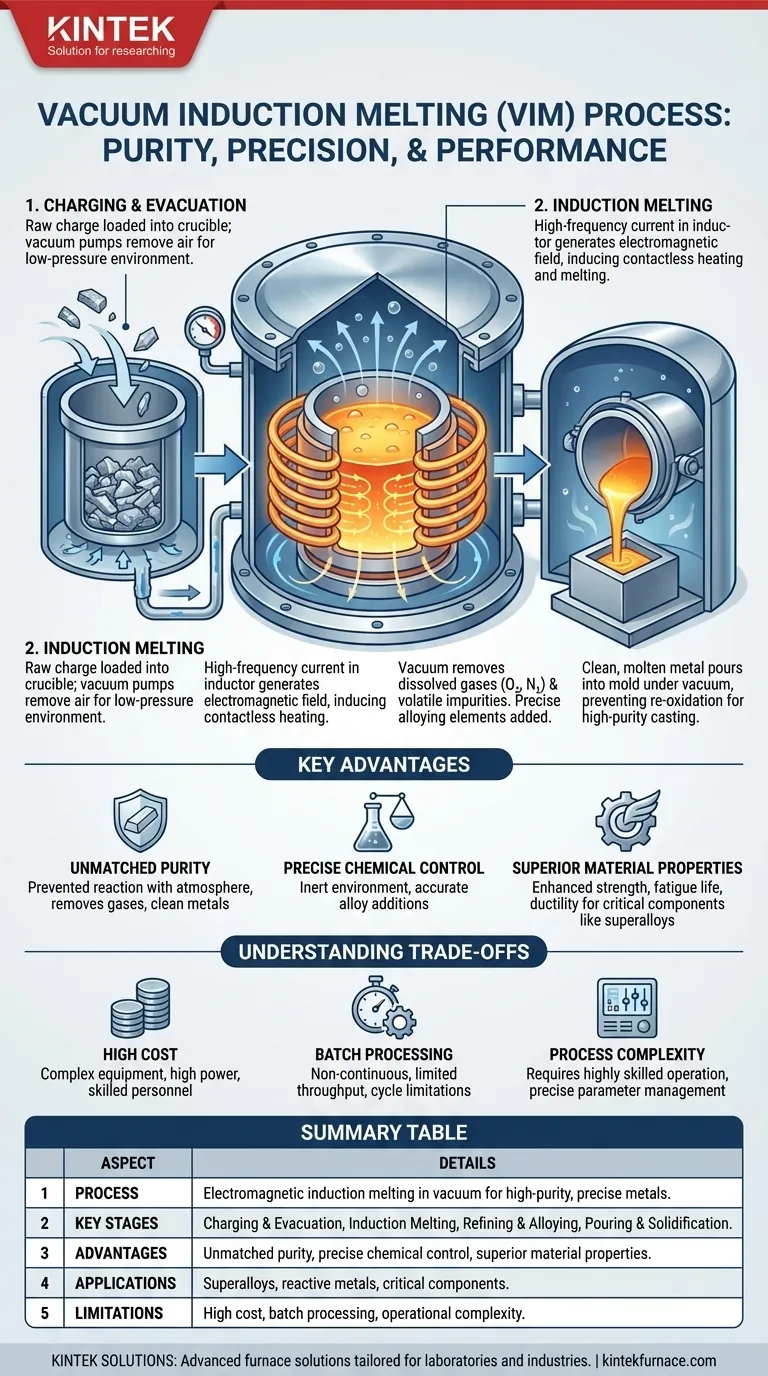

The VIM Process: A Step-by-Step Breakdown

To understand why VIM is critical for high-performance materials, we must examine each stage of the process. It is a sequence designed for maximum control and purity.

Stage 1: Charging and Evacuation

First, the raw charge material—which can be pure metals or pre-alloyed scrap—is loaded into a ceramic container called a crucible.

The crucible is housed inside a robust, vacuum-tight chamber. Once sealed, a powerful vacuum system consisting of multiple pumps removes the air, creating a low-pressure environment.

Stage 2: Induction Melting

A water-cooled copper coil, known as an inductor, surrounds the crucible but does not touch it. A high-frequency electrical current is passed through this coil.

This generates a strong alternating electromagnetic field, which induces powerful electrical eddy currents within the metallic charge material. The resistance of the metal to these currents generates intense, uniform heat, causing it to melt efficiently.

Because this all occurs in a vacuum, heat loss through convection is nearly eliminated, making the process faster and more energy-efficient than melting in air.

Stage 3: Refining and Alloying

As the metal becomes molten, the vacuum environment performs its most critical function: refining. Dissolved gases like oxygen and nitrogen, which are detrimental to material properties, are pulled out of the liquid bath.

Volatile impurities with high vapor pressures are also boiled off and removed by the vacuum system. At this stage, operators can add precise amounts of alloying elements to the melt to achieve the exact final chemical composition required.

Stage 4: Pouring and Solidification

Once the metal is fully melted, refined, and its chemistry is verified, the entire crucible assembly is tilted. This pours the clean, molten metal into a mold located inside the same vacuum chamber.

This ensures the metal is not exposed to air during the pouring step, preventing re-oxidation. The metal then solidifies within the mold, forming a high-purity ingot or a near-net-shape casting.

Key Advantages of the VIM Process

The meticulous, controlled nature of VIM delivers distinct advantages that are essential for manufacturing critical components.

Unmatched Purity

By preventing reactions with atmospheric oxygen and nitrogen, VIM produces exceptionally clean metals. The active removal of dissolved gases and volatile elements further enhances this purity, which is the primary reason for its use.

Precise Chemical Control

The vacuum provides a chemically inert environment. This allows metallurgists to make precise alloy additions without the risk of those elements being lost to oxidation, ensuring the final product meets exact specifications.

Superior Material Properties

The resulting low-gas, high-purity material has enhanced properties, including improved fatigue life, ductility, and strength. This is why VIM is essential for producing superalloys used in aircraft engine turbines and other demanding applications.

Understanding the Trade-offs

While powerful, VIM is a specialized process with specific considerations. It is not the solution for every metal production need.

High Equipment and Operational Cost

VIM furnaces are complex systems involving high-power electronics, robust vacuum chambers, and sophisticated control systems. This results in significant capital investment and higher operating costs compared to air-melting furnaces.

Batch Processing Limitations

VIM is inherently a batch process, not a continuous one. The cycle of loading, pumping down, melting, and casting limits the overall production rate, or throughput.

Process Complexity

Operating a VIM furnace requires highly skilled personnel. Managing the vacuum levels, power input, temperature, and alloying requires significant training and expertise to ensure consistent, high-quality results.

Making the Right Choice for Your Goal

Selecting VIM depends entirely on whether the end-product requirements justify the investment in its capabilities.

- If your primary focus is producing superalloys or reactive metals: VIM is the industry standard for preventing the catastrophic contamination caused by oxygen and nitrogen.

- If your primary focus is achieving the highest possible material purity: The vacuum environment is unparalleled for degassing the melt and removing volatile impurities.

- If your primary focus is manufacturing critical components with precise chemistry: VIM provides the stable, controlled environment needed for exact alloy additions without unwanted side reactions.

Ultimately, VIM is the definitive process for creating the world's most demanding, high-performance metals where purity and control are non-negotiable.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Uses electromagnetic induction in a vacuum to melt metals, ensuring purity and precise composition. |

| Key Stages | Charging and evacuation, induction melting, refining and alloying, pouring and solidification. |

| Advantages | Unmatched purity, precise chemical control, superior material properties like strength and fatigue life. |

| Applications | Superalloys for aircraft engines, reactive metals, and critical components requiring high performance. |

| Limitations | High cost, batch processing, and operational complexity requiring skilled personnel. |

Ready to elevate your metal production with high-purity solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories and industries. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're working with superalloys or reactive metals, contact us today to discuss how our expertise can help you achieve superior results—get in touch now!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing