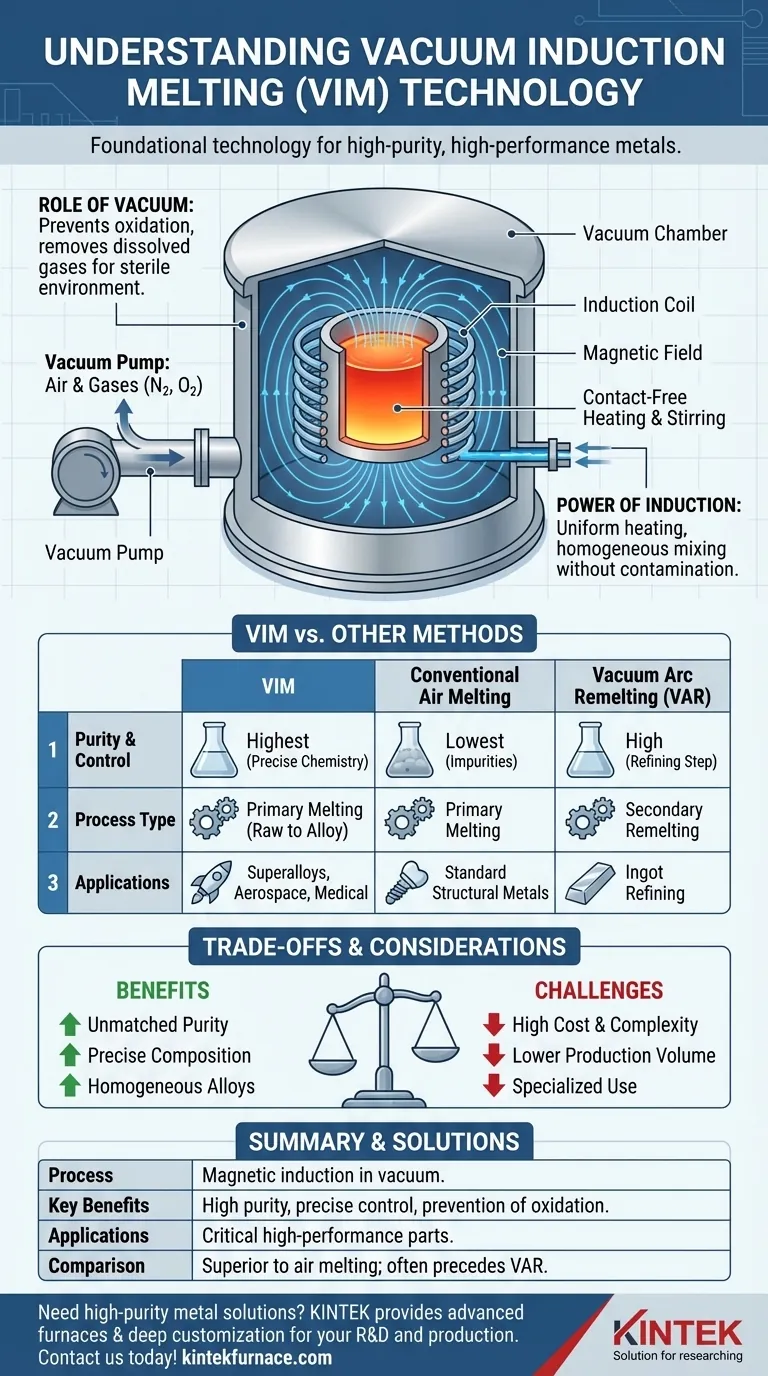

At its core, vacuum induction melting (VIM) is a manufacturing process that uses magnetic fields to melt metal inside a vacuum chamber. This technique is fundamental for creating the highest-purity metals and alloys, as the vacuum environment prevents contamination from the air and allows for the precise removal of unwanted gases and trace elements from the molten material.

The primary challenge in producing high-performance alloys is controlling contamination and chemical composition. VIM solves this by creating a sterile, closed environment, giving metallurgists exacting control over the material's final properties, something unattainable with conventional melting methods.

The Core Principle: How VIM Achieves Purity

To understand why VIM is so important, we must look at how its two key components—the vacuum and the induction heating—work together to create a superior material.

The Role of the Vacuum

The process begins by placing raw metals inside a sealed chamber and removing the air. This immediately eliminates the primary source of contamination in traditional melting: atmospheric gases like oxygen and nitrogen, which react with hot metal to form undesirable impurities and oxides.

By operating under a vacuum, VIM provides a sterile environment that prevents these reactions from ever occurring.

The Power of Induction Heating

Instead of direct flame or an electric arc, VIM uses a powerful coil to generate a magnetic field. This field induces an electric current within the metal itself, causing it to heat and melt from the inside out without any physical contact with a heating element.

This contact-free heating is critical. It not only prevents contamination from a heating source but also naturally stirs the molten bath, ensuring the alloy is perfectly mixed and has a uniform, homogeneous composition.

The Result: Unmatched Material Control

With oxidation prevented and the alloy homogeneously mixed, the vacuum environment allows for a final refining stage. Undesirable elements and dissolved gases, such as hydrogen, bubble out of the molten metal and are evacuated by the vacuum system.

This gives engineers precise control over the final chemistry, allowing them to produce alloys with extremely low levels of impurities and exact elemental proportions, meeting the stringent requirements for high-performance applications.

VIM in Context: A Comparison to Other Methods

Not all melting processes are created equal. The value of VIM becomes clear when compared to other common techniques.

Conventional Air Melting

This is the most basic method, where metal is melted in a furnace exposed to the open atmosphere. It is fast and inexpensive but results in significant impurities and a lack of chemical control. This process is suitable for standard-quality metals where high performance is not a factor.

Vacuum Arc Remelting (VAR)

VAR is another vacuum-based process, but it uses an intense electric arc to melt a pre-made metal bar (the electrode) into a water-cooled mold. It is excellent for further purifying an existing ingot into a uniform, solid shape.

VIM is a primary melting process used to create an alloy from raw materials, while VAR is often a secondary remelting step used to refine it. They are often used in sequence to achieve the highest possible quality.

Understanding the Trade-offs

While VIM offers unparalleled quality, it is a specialized tool with specific trade-offs that make it suitable for some applications but not others.

High Cost and Complexity

VIM furnaces are complex machines that are significantly more expensive to build, operate, and maintain than conventional air-melt furnaces. The process requires sophisticated vacuum systems and power supplies.

Lower Production Volume

VIM is a batch process, meaning a finite amount of material is melted in the chamber at one time. This results in lower throughput compared to continuous melting methods, making it less suitable for high-volume commodity metals.

It Is Not a Universal Solution

The extreme purity achieved by VIM is overkill for the vast majority of metal products, such as structural steel for construction or cast iron for engine blocks. The high cost is not justifiable when the application does not demand excepciónal material properties.

Making the Right Choice for Your Goal

The decision to specify a VIM-produced material depends entirely on the final performance requirements and budget.

- If your primary focus is extreme purity and precise chemical composition for critical parts: VIM is the definitive standard for producing superalloys, medical implants, and aerospace-grade materials.

- If your primary focus is refining an existing alloy ingot to achieve a better internal structure: Vacuum Arc Remelting (VAR) is a more direct and often complementary process.

- If your primary focus is high-volume, cost-effective production for standard applications: Conventional air melting is the more economical and appropriate choice.

Ultimately, vacuum induction melting is the foundational technology that enables the creation of modern, high-performance materials.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Melts metal using magnetic induction in a vacuum chamber to prevent contamination and remove gases. |

| Key Benefits | High purity, precise chemical control, homogeneous mixing, and prevention of oxidation. |

| Applications | Superalloys, medical implants, aerospace components, and other high-performance materials. |

| Comparison | Superior to air melting for purity; often used before VAR for refining. |

| Trade-offs | Higher cost, lower production volume, and complexity compared to conventional methods. |

Need high-purity metal solutions for your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're developing superalloys or medical implants, we can help you achieve unmatched material control. Contact us today to discuss how our VIM and other furnace technologies can enhance your research and production!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries