In modern metallurgy, a Vacuum Induction Melting (VIM) furnace is a highly specialized system that melts metals and alloys using electromagnetic induction within a high-vacuum chamber. Its primary function is not simply to melt material, but to refine it to an exceptional degree of purity. By removing air and other atmospheric gases, the VIM process prevents oxidation and contamination, enabling the creation of high-performance materials with precisely controlled chemistries.

A VIM furnace isn't just for melting metal; it's a precision refining tool. By removing the atmosphere, it solves the fundamental problem of contamination, allowing engineers to create ultra-pure alloys with precise chemical compositions that are impossible to achieve with conventional air-melting techniques.

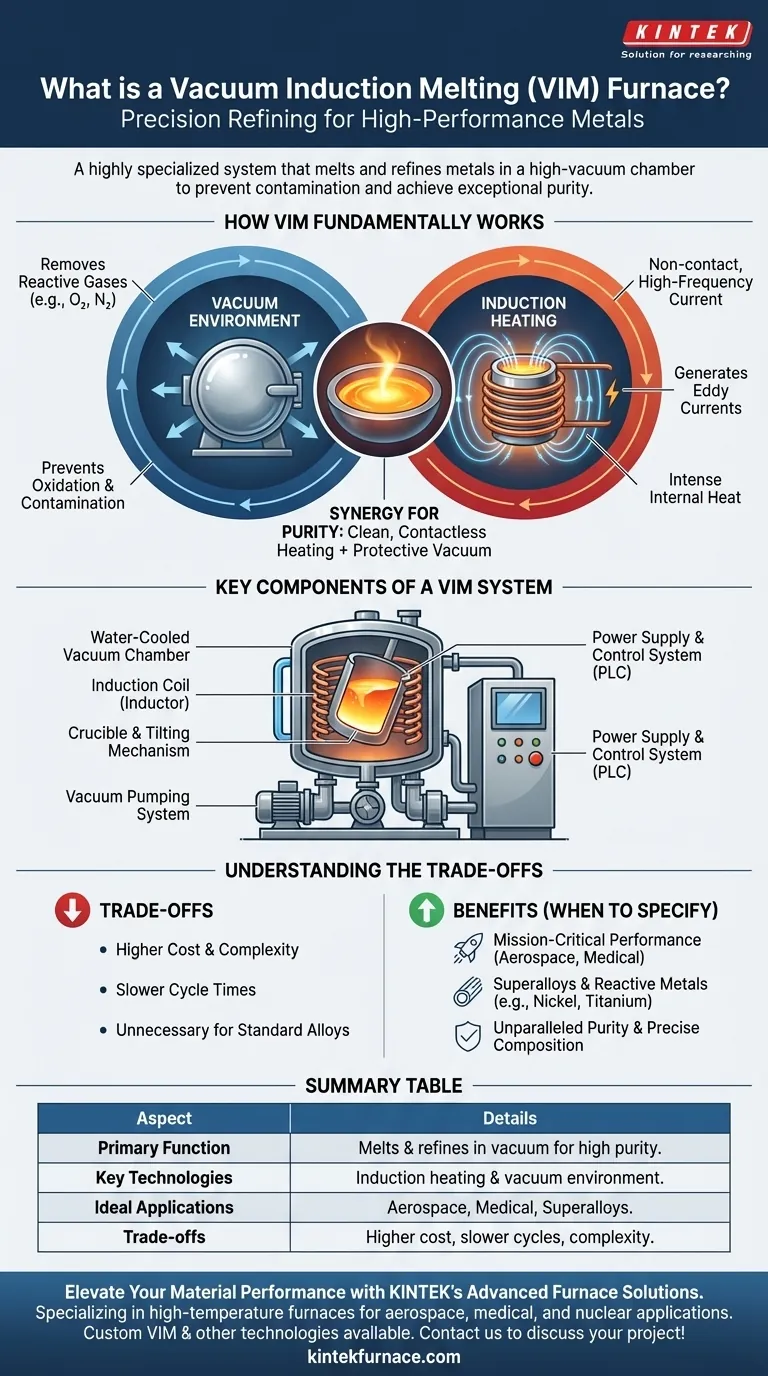

How VIM Fundamentally Works

The VIM process is defined by the synergy of two core technologies: induction heating and a vacuum environment. Understanding how these two elements work together is key to grasping the value of the furnace.

The Principle of Induction Heating

Induction heating is a non-contact method. A high-frequency alternating current is passed through a copper coil (the inductor), which generates a powerful and rapidly changing magnetic field.

When a conductive material like metal is placed within this field, the field induces strong electrical currents—known as eddy currents—within the metal itself. The metal's natural resistance to these currents generates intense, rapid heat, causing it to melt from the inside out.

The Role of the Vacuum Environment

The entire melting process takes place inside a sealed, water-cooled chamber from which the air has been pumped out to create a vacuum.

This vacuum is critical because it removes reactive gases, primarily oxygen and nitrogen. Without a vacuum, these gases would readily react with the hot metal to form oxides and nitrides, which are impurities that severely degrade the material's mechanical properties.

Combining Heat and Vacuum for Purity

The combination of clean, contactless heating and a protective vacuum is what makes the VIM process so powerful. Induction provides the energy to melt the alloy, while the vacuum prevents contamination and can even help pull dissolved gases out of the molten metal, further refining it.

Key Components of a VIM System

A VIM furnace is a complex system with several integrated parts, each serving a specific function to ensure precise and repeatable results.

The Vacuum Chamber

This is the main furnace body, typically a water-cooled, double-walled steel vessel. The water cooling is essential to protect the structure from the extreme temperatures of the molten metal inside.

The Induction Coil (Inductor)

Positioned inside the chamber, the inductor is the heart of the heating system. It is made from hollow copper tubing that is also water-cooled to prevent it from melting while it generates the intense magnetic field.

The Crucible and Tilting Mechanism

The crucible is a ceramic container that holds the charge of metal to be melted. It is designed to withstand extreme thermal shock. The entire furnace assembly is often built on a tilting mechanism that allows the operator to pour the refined, molten metal into a mold with precise control.

The Vacuum Pumping System

This is not a single pump but a series of pumps working in stages. A roughing pump first removes the bulk of the air, followed by high-vacuum pumps (like diffusion or turbomolecular pumps) to achieve the low pressures required for high-purity melting.

The Power Supply & Control System

A medium-frequency power supply provides the specialized electricity for the induction coil. Modern VIM systems are managed by a Programmable Logic Controller (PLC) and a user interface, allowing for precise control and monitoring of temperature, vacuum level, and power input throughout the melting cycle.

Understanding the Trade-offs

While VIM technology offers unparalleled quality, it is a specialized process with significant trade-offs that make it unsuitable for all applications.

Higher Cost and Complexity

VIM furnaces are significantly more expensive to purchase, operate, and maintain than conventional air-melt furnaces. The vacuum systems, sophisticated controls, and water-cooling infrastructure all add to the initial and ongoing costs.

Slower Cycle Times

The process of pumping down the chamber to a high vacuum, melting, refining, and casting takes considerably longer than a simple melt in the open air. This results in lower overall production throughput compared to other methods.

Unnecessary for Many Alloys

For a vast range of common metals and alloys—such as standard structural steel or many aluminum grades—the minor impurities introduced by air melting are acceptable. For these applications, the extreme purity offered by VIM is overkill, and the high cost cannot be justified.

When to Specify a VIM Process

Choosing VIM is a strategic decision driven by the end-use requirements of the material. Use this guide to determine if it aligns with your goals.

- If your primary focus is mission-critical performance: VIM is essential for components like aerospace turbine blades, medical implants, or nuclear parts where material failure could have catastrophic consequences.

- If your primary focus is producing superalloys or reactive metals: Materials like nickel-based superalloys, titanium, and alloys containing highly reactive elements (e.g., aluminum, zirconium) require VIM to prevent ruinous contamination from the atmosphere.

- If your primary focus is high-volume, lower-cost production: A conventional induction furnace or an electric arc furnace is a far more practical and cost-effective choice for standard-grade metals.

Ultimately, choosing VIM is a strategic decision to prioritize material purity and performance above all other manufacturing considerations.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Function | Melts and refines metals in a vacuum to achieve high purity and prevent contamination. |

| Key Technologies | Induction heating for contactless melting and vacuum environment for gas removal. |

| Main Components | Vacuum chamber, induction coil, crucible, vacuum pumps, power supply, and control system. |

| Ideal Applications | Aerospace superalloys, medical implants, reactive metals, and other mission-critical materials. |

| Trade-offs | Higher cost, slower cycle times, and complexity compared to conventional melting methods. |

Elevate Your Material Performance with KINTEK's Advanced Furnace Solutions

Are you working with high-performance alloys for aerospace, medical, or nuclear applications? KINTEK specializes in delivering cutting-edge high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Vacuum & Atmosphere Furnaces, Muffle, Tube, and Rotary Furnaces, as well as CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental and production requirements, helping you achieve superior purity and efficiency in your processes.

Contact us today to discuss how our VIM and other furnace technologies can transform your operations and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys