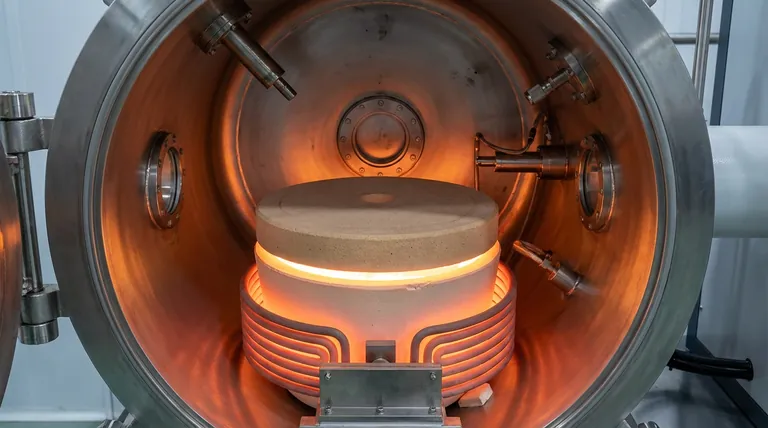

The crucible lid serves a dual purpose in the AlV55 smelting process: it acts as a critical thermal barrier to minimize heat loss and creates a controlled micro-environment to stabilize the alloy's chemical composition. By physically sealing the crucible, the lid prevents the volatile aluminum content from evaporating and escaping the melt, ensuring the final product maintains the correct elemental ratio.

The crucible lid is not merely a cover; it is a functional component that inhibits aluminum volatilization by creating a saturated vapor zone and significantly boosts thermal efficiency by blocking radiative heat loss.

Enhancing Thermal Efficiency

Minimizing Heat Radiation

The primary physical function of the crucible lid is to act as a barrier against heat radiation.

In high-temperature smelting, a significant amount of energy is lost via radiation from the exposed surface of the molten metal. The lid intercepts this radiation, reflecting heat back toward the melt rather than allowing it to dissipate into the furnace chamber.

Improving Energy Utilization

By reducing the rate of heat loss, the lid directly improves the thermal efficiency of the induction heating process.

This ensures that more input energy is utilized for melting and mixing the alloy, rather than being wasted on maintaining temperature against losses.

Stabilizing Alloy Composition

Creating a Saturated Micro-Environment

Perhaps the most critical role of the lid is its ability to create a saturated metal vapor micro-environment directly above the melt.

By trapping vapors within the crucible, the lid increases the partial pressure of metal vapors in that specific zone. This saturation effectively creates "back pressure" that inhibits the further escape of volatile elements from the liquid metal.

Preventing Aluminum Loss

Aluminum is highly volatile under vacuum conditions. Without a lid, aluminum atoms would rapidly evaporate and condense on the cooler furnace walls.

The lid drastically slows this process. This retention is vital for maintaining alloy composition stability, ensuring the final AlV55 product has the precise aluminum-to-vanadium ratio required.

Understanding the Operational Context

The Balance Between Vacuum and Volatility

It is important to recognize the trade-off inherent in vacuum smelting.

High-performance pumps are used to lower pressure below 5 Pa to remove oxygen and nitrogen, which is essential for meeting aerospace-grade purity standards.

However, this low-pressure environment naturally lowers the boiling point of metals, encouraging evaporation. The crucible lid is the necessary counter-measure that allows you to utilize high vacuum for purity without sacrificing the alloy's volatile components.

Making the Right Choice for Your Goal

To maximize the quality of your AlV55 alloy, consider the specific function the lid plays regarding your production targets:

- If your primary focus is Compositional Accuracy: Ensure the lid fit is precise to maintain the saturated vapor pressure necessary to prevent aluminum evaporation.

- If your primary focus is Energy Efficiency: utilize the lid to minimize radiative losses, allowing the system to reach and hold melting temperatures with lower power input.

By effectively managing the crucible environment, you ensure both process efficiency and material integrity.

Summary Table:

| Function | Primary Mechanism | Benefit to AlV55 Smelting |

|---|---|---|

| Thermal Barrier | Blocks/reflects radiative heat | Higher energy efficiency & faster heating |

| Vapor Control | Creates a saturated micro-environment | Inhibits aluminum evaporation |

| Composition Stability | Maintains Al:V elemental ratio | Ensures precise aerospace-grade chemistry |

| Contamination Prevention | Physical shielding | Reduces condensation on furnace walls |

Optimize Your Advanced Smelting Process with KINTEK

Precision in AlV55 alloy production requires the perfect balance of vacuum technology and thermal management. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces tailored to your unique metallurgy needs.

Whether you are refining high-purity alloys or conducting critical thermal research, our equipment ensures maximum efficiency and compositional accuracy. Contact us today to discuss your project requirements and see how our tailored solutions can elevate your laboratory standards.

References

- Bin Sun, Lanjie Li. Study on Al Evaporation during AlV55 Melting and Alloy Preparation. DOI: 10.3390/met14040466

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- How does the control system of an induction melting furnace enhance operation? Boost Efficiency and Precision in Metal Melting

- What industries primarily use vacuum induction melting furnaces? Essential for High-Performance Alloys

- What other applications beyond melting can induction heating systems perform? Unlock Precision in Joining, Heat Treating & More

- Why is a non-consumable vacuum arc melting furnace used for AlCrTiVNbx alloys? Ensure Purity & Homogeneity

- What is an induction-heated vacuum furnace and what is its primary use? Achieve Ultimate Metal Purity for High-Performance Alloys

- How does the IGBT induction melting furnace maintain constant power output? Achieve Faster, More Efficient Melting

- Why is multiple vacuum remelting necessary for Ti-33Mo-0.2C? Solve High-Moly Segregation Challenges

- Why are multiple vacuum-argon cycles necessary for an induction heating furnace? Ensure Pure Combustion Synthesis