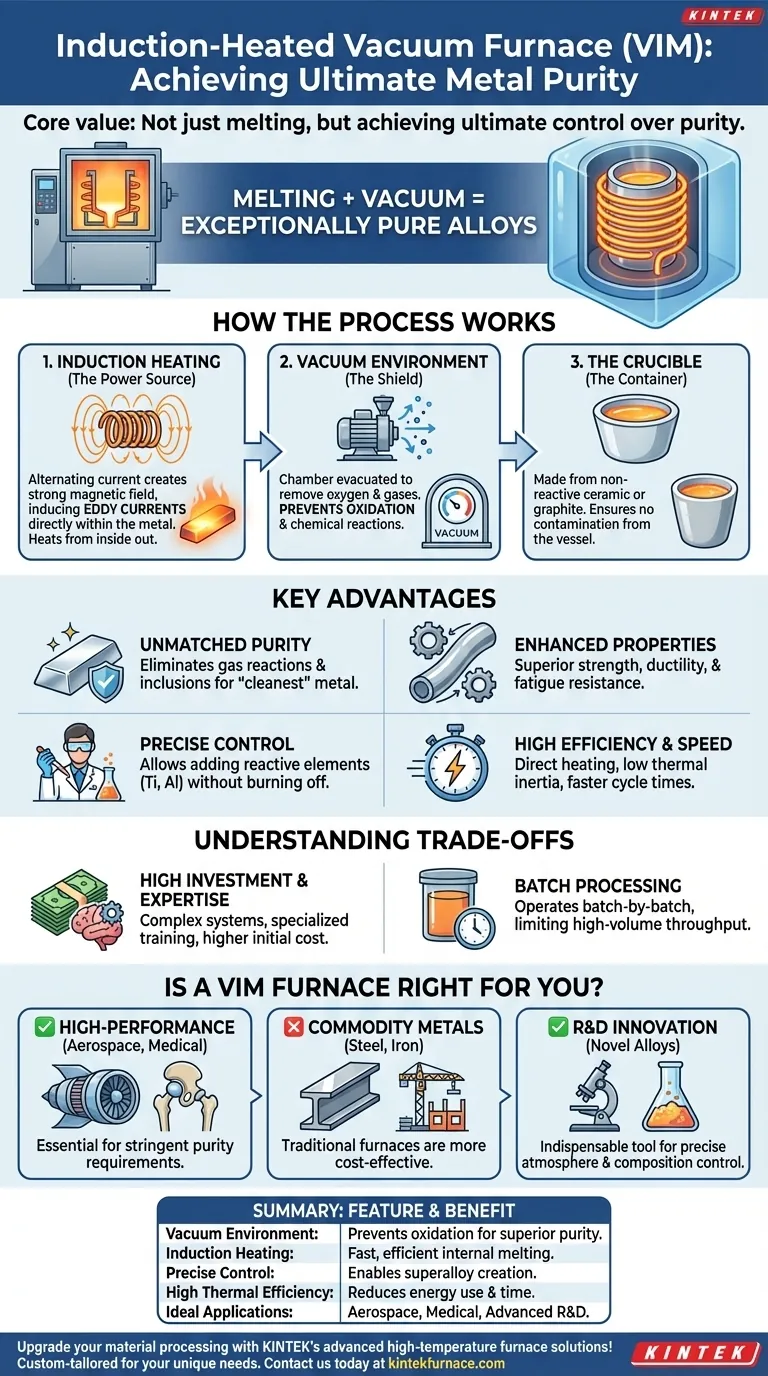

An induction-heated vacuum furnace, often called a Vacuum Induction Melting (VIM) furnace, is a highly controlled system that uses electromagnetic currents to melt metals inside a vacuum. Its primary purpose is to produce exceptionally pure, high-performance alloys by completely eliminating the risk of oxidation and atmospheric contamination that occurs during conventional melting.

The core value of this technology is not merely melting metal, but achieving ultimate control over its purity. By combining clean induction heating with a vacuum, these furnaces create materials with properties that are impossible to achieve in an open-air environment.

How the Process Achieves Superior Purity

The design of a VIM furnace is engineered around one central goal: isolating the metal from any potential contaminants during its most vulnerable molten state.

The Principle of Induction Heating

The process begins with a powerful induction coil. When an alternating electric current flows through this coil, it generates a strong, rapidly changing magnetic field.

This magnetic field penetrates the metal charge placed inside a crucible. It induces powerful electrical currents—known as eddy currents—directly within the metal itself.

The metal's natural electrical resistance causes these eddy currents to generate intense heat, melting the material from the inside out without any external flame or heating element.

The Critical Role of the Vacuum

This entire operation takes place inside a sealed, robust chamber. High-capacity pumps evacuate nearly all the air from this chamber before the melting process begins.

By removing oxygen, nitrogen, and other atmospheric gases, the vacuum prevents chemical reactions with the molten metal. This completely stops the formation of oxides and other impurities that weaken the final product.

The Crucible: The Containment Vessel

The molten metal is held within a crucible, which is typically made from a non-reactive ceramic or graphite material. This ensures that the crucible itself does not contaminate the high-purity melt.

Key Advantages of Vacuum Induction Melting

The combination of a vacuum environment and clean induction heating delivers several distinct advantages over traditional furnace technologies.

Unmatched Material Purity

By eliminating gas reactions and allowing for the removal of dissolved gases from the melt, VIM furnaces produce the "cleanest" possible metal. This is critical for high-performance applications.

Enhanced Mechanical Properties

The absence of oxide inclusions and gas porosity results in alloys with superior strength, ductility, and fatigue resistance. The material's internal structure is more uniform and sound.

Precise Compositional Control

The vacuum environment allows metallurgists to add highly reactive alloying elements, like titanium and aluminum, without them burning away upon contact with air. This enables the creation of complex, precisely defined superalloys.

High Thermal Efficiency and Speed

Induction heating is incredibly efficient because it heats the metal directly. The furnace has low thermal inertia, meaning it can heat up and cool down quickly, resulting in faster cycle times and lower energy consumption compared to refractory-lined furnaces.

Understanding the Trade-offs

While powerful, VIM technology is a specialized solution with specific considerations.

High Capital Investment

The complexity of the high-power induction systems and the robust vacuum chambers and pumps makes these furnaces significantly more expensive than their atmospheric counterparts.

Operational Expertise Required

Operating and maintaining a VIM furnace requires specialized training. Managing the vacuum systems, complex controls, and safety protocols is far more demanding than running a simple air-melt furnace.

Batch Processing Throughput

Most VIM furnaces operate on a batch-by-batch basis. While ideal for high-value materials, this can limit the overall production volume compared to continuous melting and casting methods used for commodity metals.

Is a Vacuum Induction Furnace Right for Your Goal?

The decision to use this technology depends entirely on the required quality of the final product.

- If your primary focus is producing superalloys, medical implants, or aerospace components: This technology is essential. It is often the only way to meet the stringent purity and performance requirements for these critical applications.

- If your primary focus is high-volume melting of common metals like steel or iron: A traditional arc furnace or cupola is far more cost-effective, as the extreme purity from a VIM furnace is unnecessary.

- If your primary focus is research and development of novel alloys: The precise control over atmosphere and composition makes a laboratory-scale VIM furnace an indispensable tool for material innovation.

Ultimately, choosing a vacuum induction furnace is a strategic decision to prioritize material perfection over all other considerations.

Summary Table:

| Feature | Benefit |

|---|---|

| Vacuum Environment | Prevents oxidation and gas contamination for superior purity |

| Induction Heating | Enables fast, efficient melting from inside out |

| Precise Composition Control | Allows addition of reactive elements for superalloys |

| High Thermal Efficiency | Reduces energy use and cycle times |

| Ideal Applications | Aerospace, medical implants, and advanced R&D |

Upgrade your material processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored induction-heated vacuum furnaces, including our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering unmatched purity and performance for superalloys, medical devices, and aerospace components. Contact us today to discuss how our solutions can enhance your results and efficiency!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys