Multiple vacuum remelting is a mandatory process for high molybdenum content alloys like Ti-33Mo-0.2C primarily to prevent severe compositional segregation. Because Titanium and Molybdenum possess drastically different melting points and densities, a single melting cycle fails to mix them adequately. Repeated remelting is the only reliable method to force these disparities into a homogeneous, chemically uniform ingot.

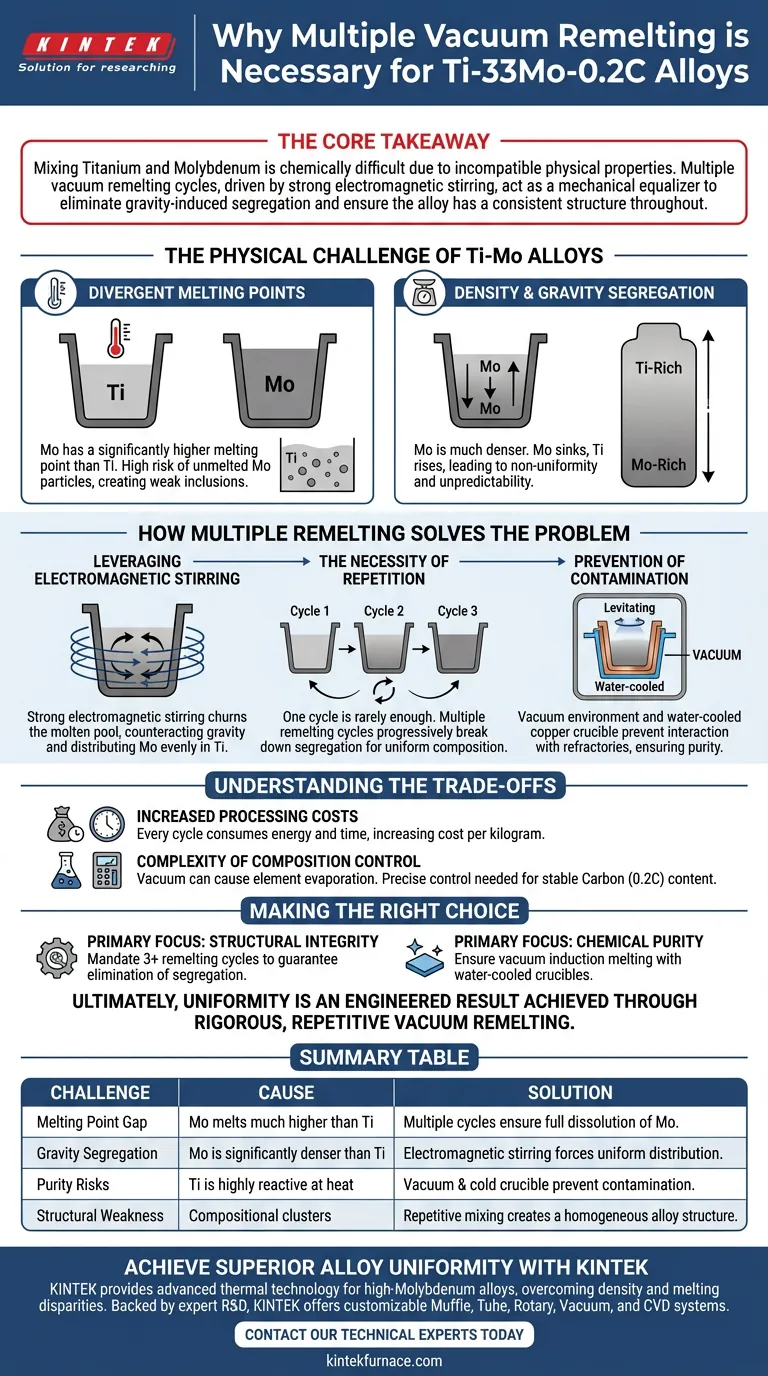

The Core Takeaway Mixing Titanium and Molybdenum is chemically difficult due to their incompatible physical properties. Multiple vacuum remelting cycles, driven by strong electromagnetic stirring, act as a mechanical equalizer to eliminate gravity-induced segregation and ensure the alloy has a consistent structure throughout.

The Physical Challenge of Ti-Mo Alloys

To understand why multiple melts are necessary, you must look at the inherent physical conflicts between the raw materials.

Divergent Melting Points

Titanium and Molybdenum do not melt at the same temperature. Molybdenum has a significantly higher melting point than Titanium.

In a single melt, there is a high risk that unmelted or partially melted Molybdenum particles will remain suspended in the liquid Titanium, creating weak points or "inclusions" in the final material.

Density and Gravity Segregation

Molybdenum is much denser than Titanium. When the alloy is in a molten state, the heavier Molybdenum naturally sinks, while the lighter Titanium rises.

This leads to gravity-induced segregation, where the bottom of the ingot is rich in Molybdenum and the top is rich in Titanium. This lack of uniformity renders the alloy unpredictable and unsuitable for high-performance applications.

How Multiple Remelting Solves the Problem

The process of vacuum remelting is not just about heating the metal; it is an active mixing process designed to overcome the physical challenges listed above.

Leveraging Electromagnetic Stirring

Vacuum remelting equipment employs strong electromagnetic stirring. This force churns the molten pool, physically counteracting the effects of gravity.

This stirring action forces the solute (Molybdenum) to distribute evenly throughout the solvent (Titanium), rather than settling at the bottom.

The Necessity of Repetition

One cycle of stirring is rarely enough to achieve perfect homogeneity in high-alloy systems.

By subjecting the ingot to multiple remelting cycles (often flipping the ingot between melts), you progressively break down any remaining segregation. This ensures that the chemical composition is uniform at both the macroscopic and microscopic scales.

Prevention of Contamination

The "vacuum" aspect of this process is equally critical. Using a water-cooled copper cold crucible under vacuum prevents the reactive Titanium liquid from interacting with traditional refractory materials.

This creates a levitation effect (or forms a thin skull) that eliminates contamination, ensuring the alloy remains pure while it is being mixed.

Understanding the Trade-offs

While multiple vacuum remelting is necessary for quality, it introduces specific challenges that you must account for in your planning.

Increased Processing Costs

Every remelting cycle consumes significant energy and time. Requiring three or four remelts dramatically increases the cost per kilogram of the final alloy compared to standard titanium grades.

Complexity of Composition Control

While remelting fixes segregation, the vacuum environment can sometimes lead to the evaporation of high-vapor-pressure elements if not carefully controlled.

However, for Ti-33Mo-0.2C, the primary focus remains on mixing the Molybdenum. The process must be tightly monitored to ensure the carbon content (0.2C) remains stable and is not lost or altered during the aggressive remelting cycles.

Making the Right Choice for Your Project

When specifying manufacturing protocols for Ti-33Mo-0.2C, align your process with your critical requirements.

- If your primary focus is Structural Integrity: Mandate multiple remelting cycles (often 3+) to guarantee the elimination of gravity-induced segregation and prevent potential failure points.

- If your primary focus is Chemical Purity: Ensure the use of vacuum induction melting with water-cooled copper crucibles to prevent oxygen pickup and refractory contamination.

Ultimately, for high-molybdenum titanium alloys, uniformity is not a natural state—it is an engineered result achieved only through rigorous, repetitive vacuum remelting.

Summary Table:

| Challenge | Cause | Solution during Remelting |

|---|---|---|

| Melting Point Gap | Mo melts much higher than Ti | Multiple cycles ensure full dissolution of Mo particles. |

| Gravity Segregation | Mo is significantly denser than Ti | Electromagnetic stirring forces uniform distribution. |

| Purity Risks | Ti is highly reactive at heat | Vacuum environment & cold crucible prevent contamination. |

| Structural Weakness | Compositional clusters | Repetitive mixing creates a homogeneous alloy structure. |

Achieve Superior Alloy Uniformity with KINTEK

Manufacturing high-molybdenum alloys like Ti-33Mo-0.2C demands precision to overcome density and melting point disparities. KINTEK provides the advanced thermal technology needed to ensure your materials meet the highest structural standards.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces—all fully customizable to your unique research or production needs. Don't settle for inconsistent alloy quality.

Contact our technical experts today to discuss how our high-vacuum furnace solutions can optimize your alloy development and manufacturing processes.

Visual Guide

References

- W. Szkliniarz, Agnieszka Szkliniarz. The Role of Titanium Carbides in Forming the Microstructure and Properties of Ti-33Mo-0.2C Alloy. DOI: 10.3390/coatings15050546

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vacuum arc melting furnace maintain material purity? Essential Synthesis for AlCrFeCuNi-(Vx) HEAs

- What are the technical advantages of using a vacuum melting furnace? Master Superior Quartz Glass Preparation

- What technological advancements are shaping the IGBT induction melting furnace market? Unlock Intelligent, Efficient Melting

- What is the role of sintering or vacuum induction furnaces in battery regeneration? Optimize Cathode Recovery

- What are the key benefits of using an IGBT Vacuum Induction Melting Furnace? Achieve Superior Metal Purity and Control

- What types of materials can channel induction furnaces melt? The Ideal High-Volume Metal Melting Solution

- What is the working principle of an induction furnace for melting gold? Discover Fast, Clean Melting for Precious Metals

- How does electromagnetic induction stirring assist in inclusion removal? Boost Purity in Vacuum Cold Crucible Furnaces