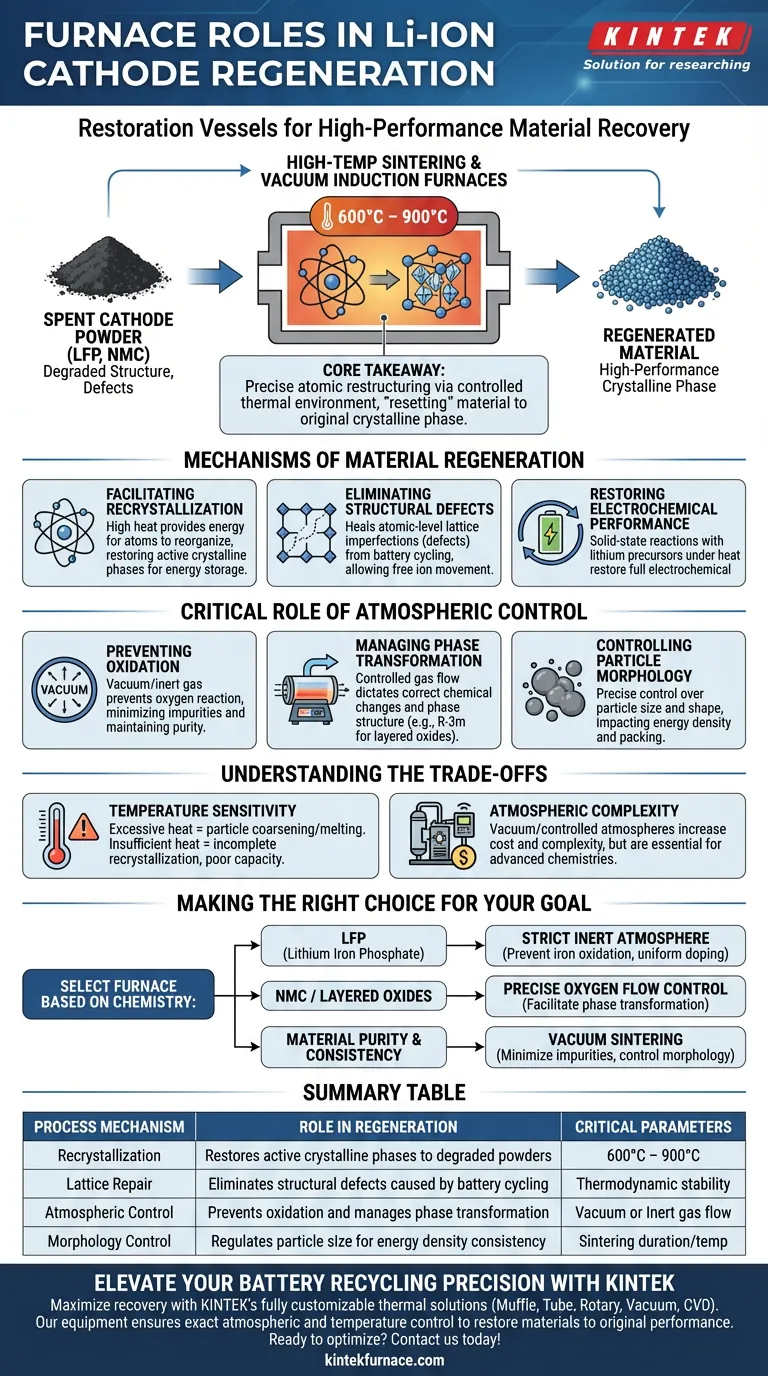

High-temperature sintering and vacuum induction furnaces serve as the critical restoration vessel in the recycling of lithium-ion battery cathode materials. Their primary role is to subject degraded powders, such as Lithium Iron Phosphate (LiFePO4) or Nickel Manganese Cobalt (NMC), to controlled thermal environments between 600°C and 900°C to reverse structural degradation.

Core Takeaway The regeneration process relies on these furnaces not merely to heat the material, but to facilitate precise atomic restructuring. By controlling the atmosphere and temperature, the equipment triggers recrystallization and defect elimination, effectively "resetting" the material to its original high-performance crystalline phase.

The Mechanisms of Material Regeneration

Facilitating Recrystallization

The primary function of these furnaces is to induce recrystallization within the spent cathode powder.

During the battery's lifecycle, the material's structure breaks down; high heat provides the energy required for atoms to reorganize.

This restores the material to specific, active crystalline phases necessary for energy storage.

Eliminating Structural Defects

Extended battery cycling introduces atomic-level imperfections, known as lattice defects, which hamper performance.

Thermal treatment at specific temperatures (600°C–900°C) provides the thermodynamic conditions to heal these defects.

This process repairs the crystal lattice, ensuring ions can move freely through the material again.

Restoring Electrochemical Performance

The ultimate goal of the furnace operation is the full restoration of electrochemical activity.

By combining the spent material with lithium precursors and subjecting them to heat, the furnace enables solid-state reactions.

This results in a regenerated cathode material that mimics the performance characteristics of newly manufactured powder.

The Critical Role of Atmospheric Control

Preventing Oxidation and Impurities

Vacuum induction furnaces differ from standard ovens by allowing for precise atmospheric manipulation.

Operating in a vacuum or inert gas environment prevents oxygen from reacting with sensitive materials during the heating phase.

This minimizes impurities and prevents oxidation, which is vital for maintaining the purity and consistency of the final product.

Managing Phase Transformation

For materials requiring specific structures, such as the R-3m space group in layered oxides, the atmosphere dictates success.

Tube furnaces and muffle furnaces ensure a continuous, controlled flow of gas (oxygen or inert) to support the correct chemical changes.

This environment ensures the complete transformation of precursors into a uniform, high-purity single-phase structure.

Controlling Particle Morphology

Beyond chemistry, these furnaces help determine the physical shape and size of the material particles.

Vacuum sintering allows for precise control over particle size and morphology, which directly impacts the battery's energy density.

Uniform particle formation leads to better packing density and more consistent battery performance.

Understanding the Trade-offs

Temperature Sensitivity

While high heat is necessary, deviations from the optimal range (600°C–900°C) can be detrimental.

Excessive temperatures may cause particle coarsening or melting, destroying the material's surface area.

Insufficient temperatures will result in incomplete recrystallization, leaving the material with poor capacity.

Atmospheric Complexity

Using vacuum or controlled atmosphere furnaces increases operational complexity and cost compared to air firing.

However, relying on simple air atmospheres is often insufficient for advanced chemistries prone to oxidation.

Operators must balance the high capital cost of vacuum equipment against the strict purity requirements of the specific cathode chemistry.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends heavily on the specific chemistry of the cathode material you are regenerating.

- If your primary focus is regenerating Lithium Iron Phosphate (LFP): Prioritize furnaces with strict inert atmosphere controls to prevent iron oxidation and ensure uniform doping incorporation.

- If your primary focus is regenerating NMC or Layered Oxides: Focus on furnaces that offer precise oxygen flow control to facilitate the correct phase transformation into layered structures.

- If your primary focus is Material Purity and Consistency: Utilize vacuum sintering capabilities to minimize impurity uptake and strictly control particle morphology.

The effectiveness of your regeneration process is defined by how precisely your thermal equipment can replicate the original synthesis conditions of the material.

Summary Table:

| Process Mechanism | Role in Regeneration | Critical Parameters |

|---|---|---|

| Recrystallization | Restores active crystalline phases to degraded powders | 600°C – 900°C |

| Lattice Repair | Eliminates structural defects caused by battery cycling | Thermodynamic stability |

| Atmospheric Control | Prevents oxidation and manages phase transformation | Vacuum or Inert gas flow |

| Morphology Control | Regulates particle size for energy density consistency | Sintering duration/temp |

Elevate Your Battery Recycling Precision with KINTEK

Maximize the recovery value of your cathode materials with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and precision manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of Li-ion regeneration. Whether you are scaling up LFP recovery or refining NMC phase transformations, our equipment ensures the exact atmospheric and temperature control needed to restore materials to their original high-performance state.

Ready to optimize your lab's recycling efficiency? Contact us today to discuss your unique sintering and vacuum requirements!

Visual Guide

References

- Rafael María Martínez Sánchez, Alfonso P. Ramallo-González. Regeneration of Hybrid and Electric Vehicle Batteries: State-of-the-Art Review, Current Challenges, and Future Perspectives. DOI: 10.3390/batteries10030101

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What role does the coil play in the IGBT melting process? It's the Key to Efficient Induction Heating

- What are the cost implications of using electric crucible furnaces? Uncover the True Total Cost of Ownership

- What are the benefits of reduced furnace lining burn loss in IGBT induction melting furnaces? Lower Total Casting Costs

- What environmental benefits do induction melting furnaces provide? Reduce Emissions & Boost Efficiency

- How does IGBT induction furnace technology enhance performance? Achieve Superior Melting Efficiency & Control

- What safety benefits does induction heating provide in the workplace? Achieve a Flameless, Contained Heating Process

- What is the primary role of a vacuum pump in induction brazing? Achieve Pure, Contamination-Free Research Results

- What is vacuum melting technology and how does it work? Unlock Pure, High-Performance Metals