Fundamentally, an IGBT induction furnace enhances performance by replacing older, inefficient power control methods with a high-speed, solid-state electronic switch. This allows for incredibly precise and rapid control over the electrical energy used in the melting process. The result is significantly less wasted power, more efficient energy conversion, and a more uniform heating cycle, leading directly to higher thermal efficiency and lower operational costs.

The core advantage of IGBT technology is not just an incremental improvement; it is a shift from brute-force power delivery to digitally precise energy management. This precision gives you a level of control over the melting process that directly translates to lower energy bills and higher-quality metal output.

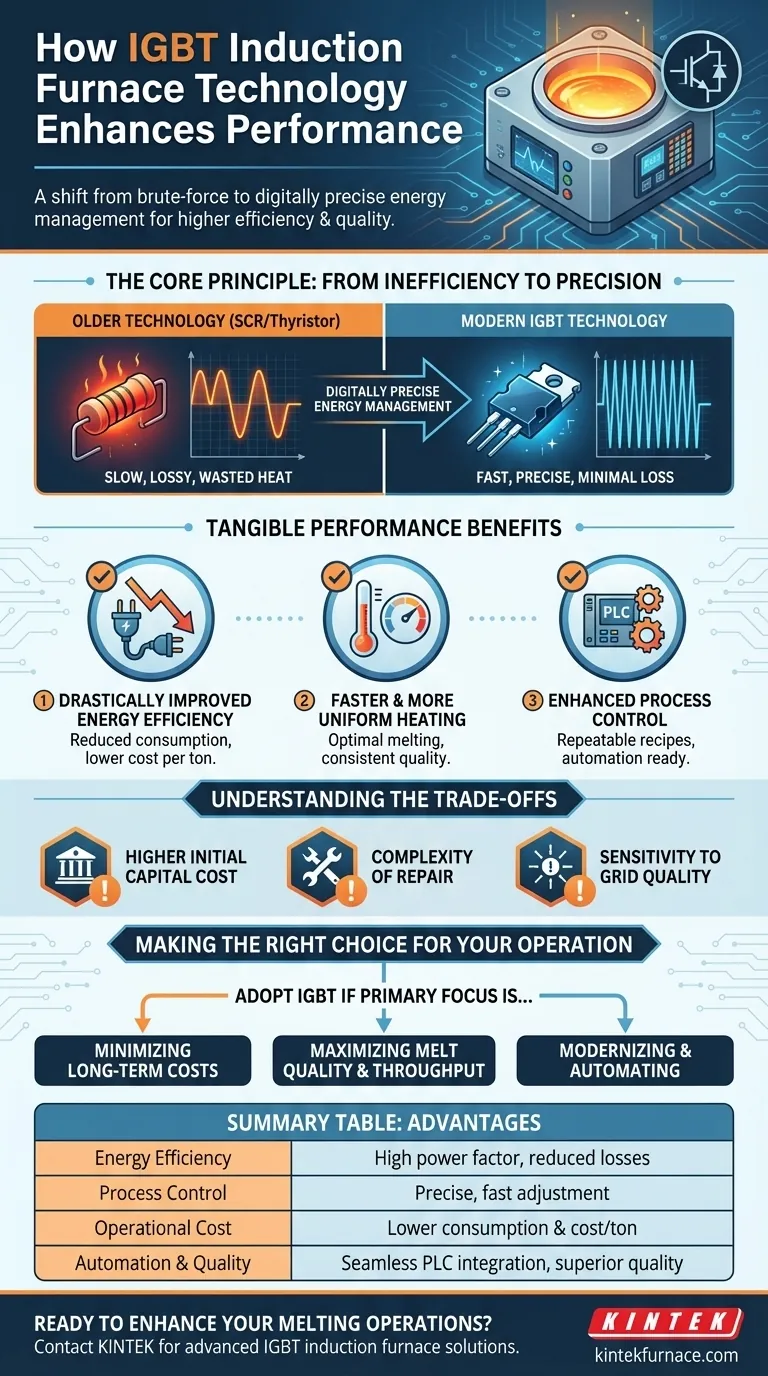

The Core Principle: From Inefficiency to Precision

To understand the impact of IGBTs, it's helpful to compare them to the older technologies they replace, such as SCR (Silicon Controlled Rectifier) or thyristor-based systems.

What an IGBT Is

An Insulated Gate Bipolar Transistor (IGBT) is a powerful semiconductor that acts as an extremely fast and efficient electronic switch.

Imagine a light dimmer. An old dimmer used a resistor to burn off excess energy as heat, wasting power. A modern digital dimmer switches the power on and off thousands of time per second to achieve the same effect with almost no waste. An IGBT does this for massive industrial currents.

The Problem with Older Technology

Older SCR-based power supplies were less efficient. They controlled power at a lower frequency, which resulted in significant electrical "noise" (harmonics) and energy losses during the conversion from grid power to the frequency needed for induction.

This inefficiency meant that a notable portion of the electricity you paid for was wasted as heat within the power supply itself, never reaching the metal in the furnace.

How IGBTs Solve This

IGBTs operate at much higher switching frequencies. This high-speed switching allows the power supply to create a clean, optimized power waveform.

This process ensures that the power factor remains close to a perfect 1.0, meaning nearly all the energy drawn from the grid is converted into useful work for melting metal. The precise control enables the system to adapt instantly to changing conditions within the furnace.

Tangible Performance Benefits

This shift in technology from slow and lossy to fast and efficient produces clear, measurable advantages in a foundry or metal processing environment.

Drastically Improved Energy Efficiency

Because IGBTs waste very little energy as heat during power conversion, overall energy consumption can be reduced significantly compared to older systems. This directly lowers the furnace's cost per ton of melted metal.

Faster and More Uniform Heating

The ability to precisely manage power allows the furnace to maintain an optimal melting profile. Energy is delivered consistently and efficiently throughout the cycle.

This leads to faster melt times and a more homogenous temperature in the molten bath, improving the metallurgical quality of the final product and reducing the chance of defects.

Enhanced Process Control and Automation

IGBT power supplies are digitally controlled by nature. This makes them easy to integrate with modern PLC (Programmable Logic Controller) systems and plant-wide automation.

Operators can program and execute specific "recipes" for different alloys, ensuring perfect repeatability, reducing human error, and creating a more predictable and reliable production process.

Understanding the Trade-offs

While IGBT technology is superior in performance, it is not without its considerations. Objectivity requires acknowledging the trade-offs involved in its adoption.

Higher Initial Capital Cost

An IGBT-based induction furnace system typically has a higher upfront purchase price than a traditional SCR system. The advanced electronics and control systems contribute to this higher initial investment.

Complexity of Repair

The sophisticated nature of an IGBT power supply means that troubleshooting and repair require a higher level of technical expertise in electronics. A failure is not a simple mechanical fix and may require specialized technicians or support from the manufacturer.

Sensitivity to Electrical Grid Quality

High-frequency power electronics can be more sensitive to significant fluctuations, surges, or poor power quality from the electrical grid. A robust and clean power source is important for ensuring the longevity and reliability of the IGBT components.

Making the Right Choice for Your Operation

Choosing the right furnace technology depends on your specific operational goals and financial priorities.

- If your primary focus is minimizing long-term operational costs: The superior energy efficiency of an IGBT system will deliver substantial savings on electricity bills that can quickly justify the higher initial investment.

- If your primary focus is maximizing melt quality and throughput: The precise and repeatable process control offered by IGBTs ensures higher metallurgical quality, faster melt cycles, and reduced scrap rates.

- If your primary focus is modernizing and automating your facility: The digital nature of IGBT controls is essential for integration with modern factory automation, enabling data logging, remote monitoring, and recipe management.

Ultimately, adopting IGBT technology is an investment in precision, efficiency, and direct control over your entire melting process.

Summary Table:

| Performance Aspect | IGBT Technology Advantage |

|---|---|

| Energy Efficiency | Significantly higher power factor (>0.95) and reduced energy losses |

| Process Control | Precise, high-speed power adjustment for uniform heating and faster melt times |

| Operational Cost | Lower electricity consumption and cost per ton of melted metal |

| Automation & Quality | Seamless integration with PLCs for repeatable recipes and superior metallurgical quality |

Ready to enhance your melting operations with precision and efficiency?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse foundries and metal processors with advanced IGBT induction furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique melting requirements.

Contact us today to discuss how our high-performance furnace technology can lower your operational costs and improve your metal quality. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing