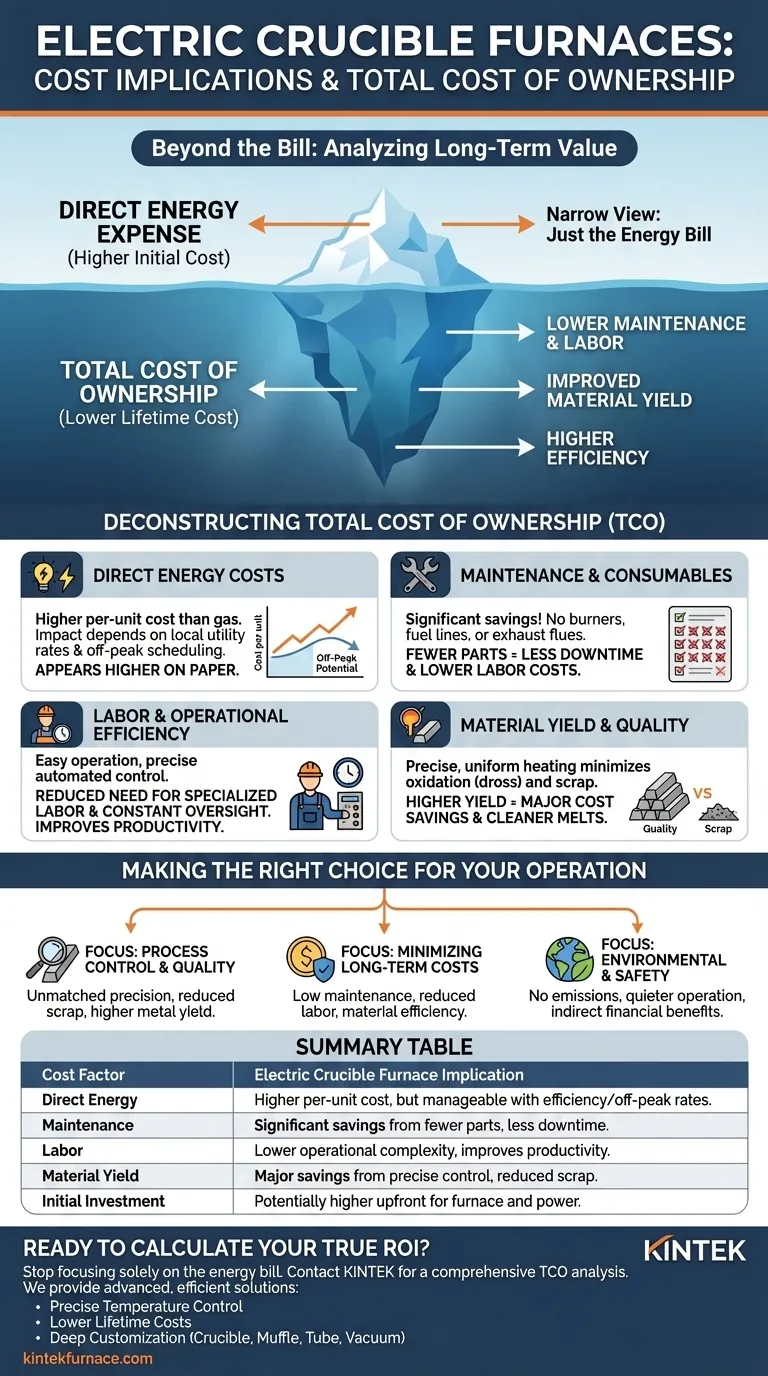

When evaluating electric crucible furnaces, the most immediate cost implication is often a higher direct energy expense compared to fuel-fired alternatives. However, this is a narrow view, as the total cost of ownership is frequently lower due to significant savings in maintenance, labor, and improved material yield. A true assessment must look beyond the monthly electricity bill.

Focusing only on the energy bill when considering an electric crucible furnace can be a costly mistake. The "deep need" is not just to melt metal, but to do so efficiently and profitably. A holistic view of the Total Cost of Ownership (TCO) reveals that lower maintenance and higher operational efficiency often make electric furnaces the more economical choice in the long run.

Deconstructing the Total Cost of Ownership

A furnace is a long-term asset, and its true cost extends far beyond the initial purchase price or the cost of fuel. A comprehensive analysis includes direct energy consumption, maintenance, labor, and material efficiency.

Direct Energy Costs (The Obvious Factor)

The most cited drawback is the cost of electricity. In many regions, the price per unit of energy (BTU or kWh) for electricity is higher than for natural gas or propane.

This makes the direct "fuel" cost of an electric furnace appear higher on paper. The actual impact, however, is highly dependent on local utility rates and the furnace's overall efficiency.

Maintenance and Consumable Costs (The Hidden Savings)

Electric crucible furnaces have a distinct advantage in maintenance simplicity. This is a major source of cost savings over the equipment's lifetime.

Because there are no burners, fuel lines, or exhaust flues, there are far fewer components to service, repair, or replace. This translates directly into less downtime, fewer spare parts to stock, and lower labor costs for maintenance technicians.

Labor and Operational Efficiency

Crucible furnaces are known for being easy to operate, and electric models amplify this benefit. They require minimal specialized training to run effectively.

Precise, often automated, temperature controls reduce the need for constant manual oversight. This allows operators to manage other tasks, improving overall labor productivity and ensuring consistent, repeatable melt quality without relying on a highly skilled artisan.

Material Yield and Quality

This is where electric furnaces often create the most significant financial return. The gentle, uniform heating and lack of combustion byproducts directly improve the quality of the molten metal.

This precise control minimizes metal loss to oxidation (dross formation). An improvement in material yield of even 1-2% can result in substantial cost savings over thousands of pounds of processed metal. Furthermore, cleaner melts reduce casting defects and scrap rates, another major financial drain.

Understanding the Trade-offs

While the TCO is often favorable, it's crucial to understand the specific context and potential downsides before making an investment.

The Impact of Electricity Tariffs

Your facility's electricity tariff structure is a critical factor. Operations with "time-of-use" rates can dramatically reduce energy costs by scheduling melting during off-peak hours. Conversely, running during peak demand periods can make costs prohibitive.

Initial Capital Investment

An electric furnace system, including the necessary power supply infrastructure, can sometimes have a higher upfront capital cost than a comparable fuel-fired unit. This initial expense must be weighed against the projected long-term operational savings.

Production Volume and Scale

For very large-scale, continuous melting applications, the sheer volume of energy consumed may favor the lower per-unit energy cost of gas in some regions. Electric furnaces excel in batch processing, holding applications, and scenarios where alloy purity and temperature precision are paramount.

Making the Right Choice for Your Operation

Your ideal furnace solution depends on balancing these cost factors against your specific operational goals.

- If your primary focus is process control and material quality: The precise temperature management of an electric furnace is unmatched, delivering returns through reduced scrap and higher metal yield.

- If your primary focus is minimizing long-term operational costs: An electric crucible furnace is a very strong contender due to its low maintenance, reduced labor needs, and material efficiency.

- If your primary focus is environmental compliance and workplace safety: The lack of emissions and quieter operation of an electric furnace provides significant benefits that also carry indirect financial advantages.

Ultimately, a comprehensive Total Cost of Ownership analysis is the only way to make a truly informed and profitable decision for your operation.

Summary Table:

| Cost Factor | Electric Crucible Furnace Implication |

|---|---|

| Direct Energy | Higher per-unit cost than gas, but efficiency and off-peak rates can mitigate this. |

| Maintenance | Significant savings from fewer parts (no burners, fuel lines) and less downtime. |

| Labor | Lower operational complexity improves productivity and reduces specialized labor needs. |

| Material Yield | Major savings from precise control, reducing oxidation (dross) and scrap rates. |

| Initial Investment | Potentially higher upfront cost for furnace and power infrastructure. |

Ready to calculate the true ROI for your melting operation?

Stop focusing solely on the energy bill. A comprehensive Total Cost of Ownership analysis is essential for a profitable long-term investment. KINTEK specializes in helping foundries and metallurgical labs like yours make data-driven decisions.

We provide the advanced, efficient solutions you need:

- Precise Temperature Control: Achieve cleaner melts and higher material yield with our electric furnaces.

- Lower Lifetime Costs: Benefit from our designs that minimize maintenance and operational complexity.

- Deep Customization: Our strong R&D and in-house manufacturing capabilities allow us to tailor a furnace solution—whether it's a Crucible, Muffle, Tube, or Vacuum Furnace—to your exact process requirements.

Let's analyze your specific costs and requirements together. Contact our experts today to discover how a KINTEK electric furnace can enhance your efficiency and profitability.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency