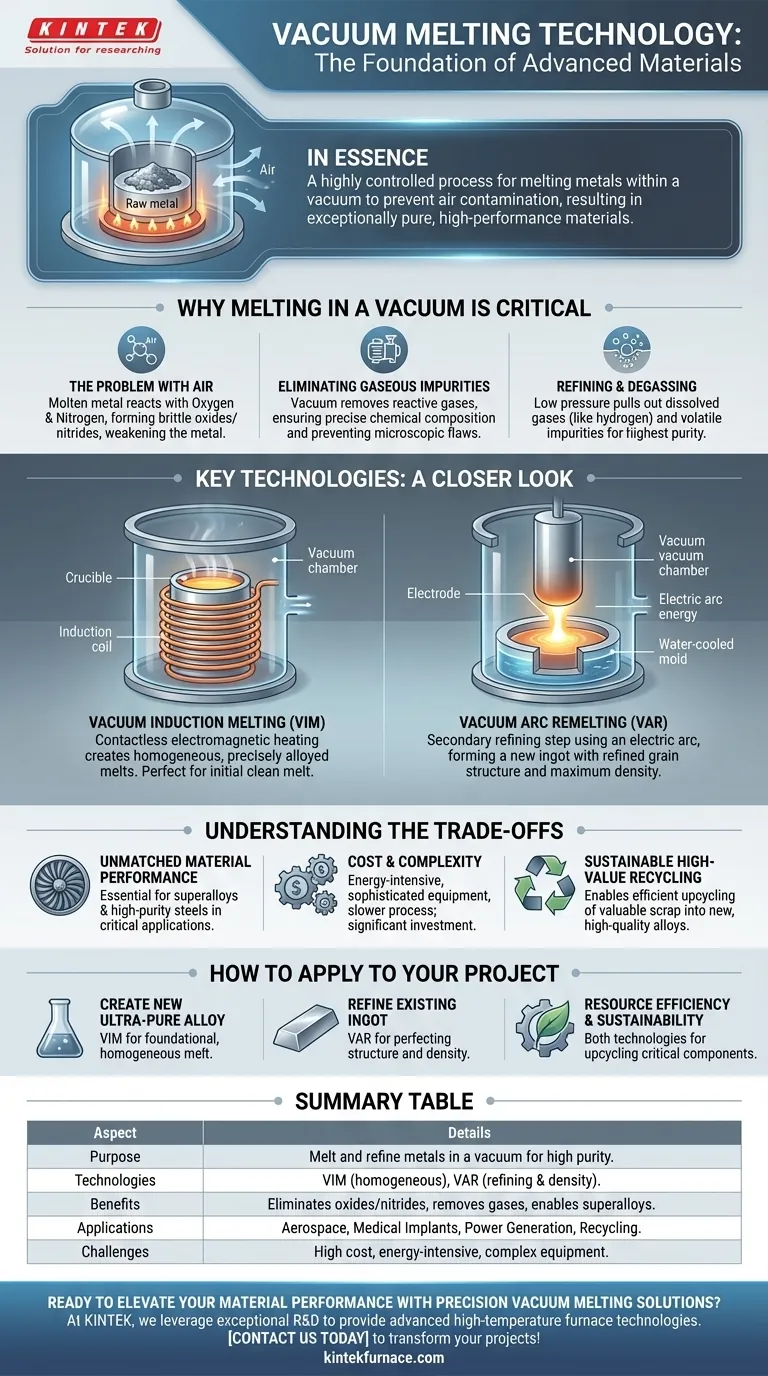

In essence, vacuum melting technology is a highly controlled process for melting metals within a vacuum to prevent contamination from air. It works by placing raw metal inside a sealed chamber, removing the air to create a vacuum, and then heating the metal until it melts, typically using induction coils or an electric arc. This environment eliminates unwanted chemical reactions with oxygen and nitrogen, resulting in exceptionally pure, high-performance metals and alloys.

The core purpose of vacuum melting is not simply to melt metal, but to actively refine it. By removing the surrounding atmosphere, the process purges gaseous impurities and prevents the formation of internal defects, enabling the creation of advanced materials that would be impossible to produce in open air.

Why Melting in a Vacuum is Critical

Melting metal at extremely high temperatures makes it highly reactive. Exposing it to normal air under these conditions introduces significant problems that vacuum melting is specifically designed to solve.

The Problem with Air

Standard air is composed of roughly 78% nitrogen and 21% oxygen. When in contact with molten metal, these gases readily form oxides and nitrides—brittle, non-metallic inclusions that compromise the metal's strength, ductility, and overall integrity.

Eliminating Gaseous Impurities

Creating a vacuum within the melting chamber removes these reactive gases. This prevents contamination from the atmosphere, ensuring the final chemical composition of the alloy is precisely what was intended, without the microscopic flaws that weaken the material.

Refining and Degassing the Metal

The vacuum environment does more than just shield the melt; it actively purifies it. The low-pressure conditions help pull out dissolved gases (like hydrogen) and other volatile, low-boiling-point impurities that were already trapped within the solid raw material. This "degassing" effect is crucial for achieving the highest levels of purity.

A Closer Look at the Key Technologies

While the principle is consistent, different methods are used to apply heat within the vacuum. The two most prominent are Vacuum Induction Melting (VIM) and Vacuum Arc Remelting (VAR).

Vacuum Induction Melting (VIM)

VIM uses a powerful induction coil that generates an electromagnetic field to heat and melt the metal inside a crucible, all within the vacuum chamber. This method is contactless, meaning the heat source never touches the metal, preventing contamination.

The electromagnetic field also creates a natural stirring action in the molten bath. This ensures the mixture is perfectly homogeneous, which is essential for creating alloys with a precise and uniform composition. VIM offers exceptional control over both temperature and chemistry.

Vacuum Arc Remelting (VAR)

VAR is often used as a secondary refining step after an initial melt (frequently done via VIM). In this process, the metal to be refined is first formed into a large cylindrical electrode.

Inside the vacuum chamber, a high-power electric arc is struck between this electrode and a base plate. The intense heat of the arc progressively melts the tip of the electrode, and the molten metal drips down to solidify in a water-cooled copper mold, forming a new, highly purified ingot with a refined grain structure.

Understanding the Trade-offs

Vacuum melting delivers unparalleled quality, but it is a specialized process with inherent complexities. Understanding these factors is key to appreciating its role in modern manufacturing.

The Benefit: Unmatched Material Performance

The primary driver for using vacuum melting is the production of superalloys and high-purity steels. These materials are essential for applications where failure is not an option, such as jet engine turbine blades, medical implants, and critical components in the aerospace and power generation industries.

The Challenge: Cost and Complexity

Creating and maintaining an industrial-scale vacuum is energy-intensive and requires sophisticated, expensive equipment. The process is slower and more complex than conventional air melting, making it a significant investment reserved for materials where performance justifies the cost.

The Advantage: Sustainable High-Value Recycling

Vacuum melting plays a vital role in a circular economy. It enables the efficient recycling of valuable scrap metal, such as old turbine parts. The refining process removes any impurities the scrap may have picked up, allowing it to be reconstituted into new, high-quality alloys instead of being downcycled into a lower-grade material.

How to Apply This to Your Project

Your choice of technology is driven entirely by the required purity and structural integrity of the final material.

- If your primary focus is creating a new, ultra-pure alloy with precise chemical composition: VIM is the foundational process for creating a clean and homogeneous initial melt from raw materials.

- If your primary focus is refining an existing ingot to achieve maximum density and an ideal crystal structure: VAR is the secondary process used to perfect the material, removing final impurities and controlling solidification.

- If your primary focus is resource efficiency and sustainability: Both technologies are critical for upcycling high-value scrap metal back into mission-critical components, reducing waste and the need for virgin raw materials.

Ultimately, vacuum melting technology is the invisible foundation supporting many of the most advanced and reliable machines in our modern world.

Summary Table:

| Aspect | Details |

|---|---|

| Purpose | Melt and refine metals in a vacuum to prevent contamination and achieve high purity. |

| Key Technologies | Vacuum Induction Melting (VIM) for homogeneous alloys; Vacuum Arc Remelting (VAR) for refining and density. |

| Benefits | Eliminates oxides/nitrides, removes dissolved gases, enables superalloys for critical applications. |

| Applications | Aerospace (e.g., turbine blades), medical implants, power generation, sustainable recycling. |

| Challenges | High cost, energy-intensive, complex equipment, slower than conventional methods. |

Ready to elevate your material performance with precision vacuum melting solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace technologies tailored for your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization capabilities. Whether you're in aerospace, medical, or energy sectors, we can help you achieve superior purity and reliability. Contact us today to discuss how our solutions can transform your projects!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity