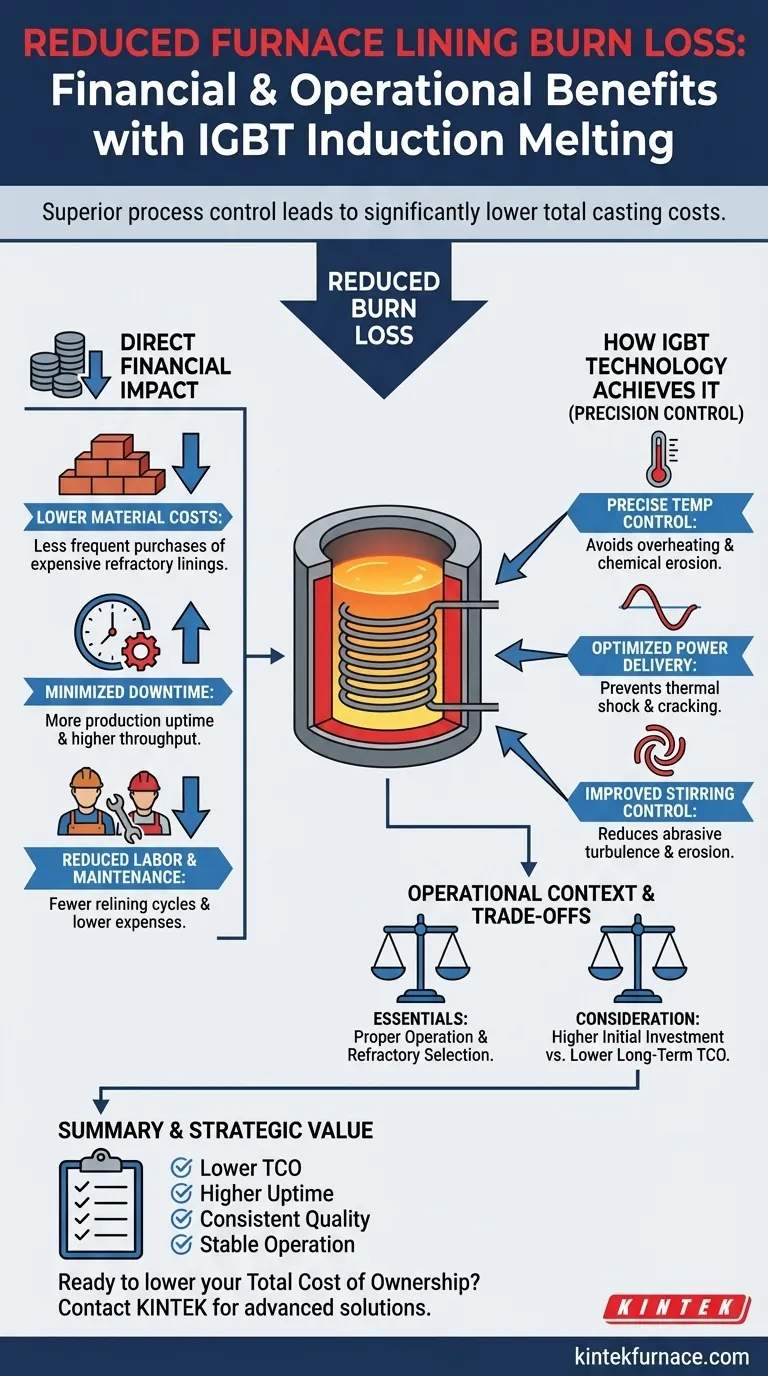

In short, reduced furnace lining burn loss in an IGBT induction furnace directly and significantly lowers your total casting costs. This benefit is a direct consequence of the superior process control inherent in IGBT technology, which minimizes the thermal and physical stresses that degrade the refractory lining over time.

The core takeaway is that reduced lining loss is not just a maintenance footnote; it is a primary driver of financial efficiency. It stems from the precise energy control of IGBT systems, leading to fewer material purchases, less downtime, and a more stable, productive melting operation.

The Direct Financial Impact of Reduced Burn Loss

The wear and tear on your furnace's refractory lining is a major operational expense. Minimizing this "burn loss" translates directly into tangible savings across your operation.

Lowering Direct Material Costs

The most obvious benefit is a reduction in the consumption of expensive refractory materials. A longer-lasting lining means you purchase and install new linings less frequently.

Over the course of a year, even a modest extension in lining life can result in substantial savings on material procurement.

Minimizing Production Downtime

Replacing a furnace lining is a time-consuming process that brings production to a complete halt. This planned downtime interrupts workflow and limits total output.

By extending the life of the lining, you decrease the frequency of these shutdowns, maximizing furnace availability and increasing overall plant throughput.

Reducing Labor and Maintenance Expenses

The process of chipping out an old lining and installing a new one is labor-intensive and requires skilled personnel.

Fewer relining cycles mean a direct reduction in the associated labor costs and the ancillary expenses tied to the maintenance process.

How IGBT Technology Achieves Lower Burn Loss

The reason IGBT-powered furnaces excel at preserving the lining is their ability to manage energy with exceptional precision. This control mitigates the primary causes of refractory degradation.

The Role of Precise Temperature Control

IGBT systems allow for optimized and stable frequency control. This enables the furnace to maintain the molten bath at a consistent target temperature without significant overshooting.

Avoiding excessive superheating is critical, as high temperatures dramatically accelerate the chemical erosion of the refractory lining.

Optimized Power Delivery

IGBT technology provides the ability to ramp power up and down smoothly and efficiently. This prevents the severe thermal shock that can crack and damage the lining.

A gentler heating and cooling cycle puts far less physical stress on the refractory material, preventing premature failure.

Improved Control Over Melt Stirring

The precision of the induction field in an IGBT furnace allows for better control over the stirring action within the melt.

This ensures homogenous temperatures while avoiding the overly violent, abrasive turbulence that can physically erode the furnace walls.

Understanding the Trade-offs and Operational Context

While IGBT technology offers a distinct advantage in reducing lining loss, it is not a magic bullet. Real-world results depend on a holistic operational approach.

Proper Operation is Still Essential

The benefits of advanced technology can be negated by poor operating practices. Consistently overcharging the furnace, using improper charge materials, or failing to manage slag can still lead to premature lining failure.

Operator training and adherence to best practices remain paramount to maximizing the life of the refractory.

Refractory Selection Remains Critical

Reduced burn loss does not mean you can compromise on the quality of your lining material. The refractory must still be correctly matched to the specific metals being melted and the operating temperatures.

Using an inappropriate or low-grade lining will undermine the control benefits provided by the IGBT system.

Initial Investment vs. Long-Term ROI

Furnaces equipped with modern IGBT power supplies may represent a higher initial capital investment compared to older technologies.

However, the significant long-term savings from reduced energy consumption, higher productivity, and lower maintenance costs—including lining replacement—are essential factors in calculating the total cost of ownership (TCO).

Making the Right Choice for Your Foundry

Understanding how reduced burn loss impacts your bottom line allows you to evaluate an IGBT furnace not just on its purchase price, but on its long-term value to your operation.

- If your primary focus is minimizing Total Cost of Ownership: The reduced expenditure on refractory materials, labor, and downtime makes a significant contribution to a lower TCO.

- If your primary focus is maximizing production uptime: Longer lining life is one of the most direct ways to increase furnace availability and achieve higher plant throughput.

- If your primary focus is ensuring consistent melt quality: A stable and intact furnace lining provides a cleaner, more predictable environment, which is fundamental to achieving consistent metallurgical results.

Ultimately, viewing reduced lining wear as a key performance indicator empowers you to make a more strategic and financially sound investment in your melting technology.

Summary Table:

| Benefit | Impact on Your Foundry |

|---|---|

| Lower Material Costs | Reduced frequency of purchasing expensive refractory linings. |

| Minimized Downtime | Less frequent relining means more production uptime and higher throughput. |

| Reduced Labor & Maintenance | Fewer relining cycles cut skilled labor and associated maintenance expenses. |

| Stable, Consistent Melts | An intact lining provides a cleaner, more predictable melting environment. |

Ready to significantly lower your total cost of ownership?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal processing solutions. Our expertise in high-temperature furnace technology, including advanced induction systems, can help you achieve the precise control needed to minimize lining burn loss, reduce downtime, and maximize productivity.

Let's discuss how our solutions can be tailored to your unique foundry requirements. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification