In the modern industrial workplace, the most significant safety benefit of induction heating is its fundamentally flameless and localized nature. By using electromagnetic fields to generate heat directly within a conductive part, it eliminates the primary hazards of open flames, such as ambient heat, burn risks, and the creation of harmful combustion byproducts.

The core safety advantage of induction heating is not just the absence of flame, but the shift from an uncontrolled, ambient heating process to a precise, contained, and highly repeatable energy source. This fundamentally changes the risk profile of any heating application.

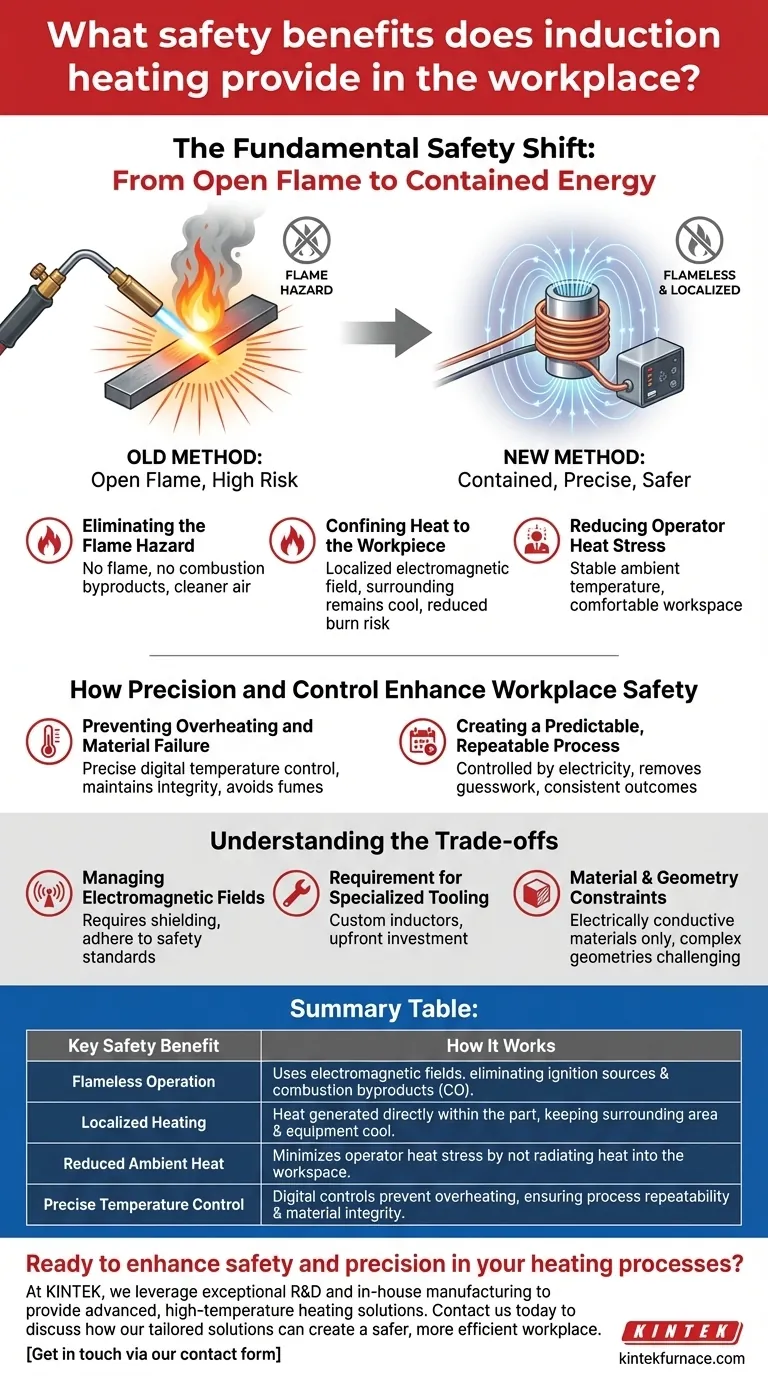

The Fundamental Safety Shift: From Open Flame to Contained Energy

Traditional heating methods rely on external, open-flame sources that heat the environment as much as the workpiece. Induction heating inverts this model, creating a safer, cleaner, and more controlled operational environment.

Eliminating the Flame Hazard

An open flame is an inherent ignition source. By design, induction heating has no flame, which immediately removes the risk of igniting flammable materials, liquids, or gases in the vicinity.

This flameless process also means there are no combustion byproducts, such as carbon monoxide or other noxious fumes. This results in cleaner air quality and a healthier environment for operators, often eliminating the need for extensive ventilation systems.

Confining Heat to the Workpiece

Induction heating is remarkably localized. The electromagnetic field 집중s energy only on the metal part placed inside or near the induction coil.

The surrounding equipment and air remain cool to the touch. This drastically reduces the risk of accidental contact burns for operators, which is a common hazard with furnaces or torches where the entire apparatus becomes dangerously hot.

Reducing Operator Heat Stress

Because heat is not radiating into the surrounding area, the ambient temperature of the workspace remains stable. This creates a much more comfortable and safer working condition, minimizing the risk of heat stress and fatigue for personnel.

How Precision and Control Enhance Workplace Safety

Beyond the absence of flame, the digital control and precision inherent in induction technology add another layer of safety by making the heating process predictable and repeatable.

Preventing Overheating and Material Failure

Induction systems allow for precise temperature control. Operators can set and maintain an exact temperature, preventing the workpiece from overheating.

Overheating can compromise a material's structural integrity or release toxic fumes from coatings or alloys. By eliminating this variable, induction heating ensures both product quality and operator safety.

Creating a Predictable, Repeatable Process

The process is controlled by electricity, not by an operator's visual judgment of flame color or position. This removes guesswork and variability, leading to a highly repeatable and consistent outcome every time. A predictable process is inherently a safer process, as it minimizes the chance of unexpected events or errors.

Understanding the Trade-offs

While the safety benefits are clear, induction heating is not a universal solution. Acknowledging its limitations is critical for a balanced assessment.

Managing Electromagnetic Fields

Induction heaters generate strong, high-frequency electromagnetic fields (EMF). While the heat is localized, these fields are not. Modern systems are designed with shielding, and facilities must adhere to strict safety standards to ensure operator exposure remains well below established safety limits.

Requirement for Specialized Tooling

Effective induction heating relies on inductors (coils) designed specifically for the part's geometry. Designing and manufacturing these custom copper inductors can be complex and costly, representing a significant initial investment.

Material and Geometry Constraints

The process is only effective for electrically conductive materials, primarily metals. It is not suitable for heating plastics, ceramics, or other non-conductive materials. Complex part geometries can also be challenging to heat evenly, requiring advanced coil engineering.

Making the Right Choice for Your Process

Ultimately, the decision to use induction heating should be based on your specific operational goals, safety priorities, and material requirements.

- If your primary focus is maximizing operator safety: Induction heating is unequivocally superior to flame-based methods due to its flameless, localized, and fume-free operation.

- If your primary focus is process quality and consistency: The precise digital control of induction heating minimizes defects and ensures repeatability, which indirectly contributes to a safer, more predictable outcome.

- If you are working with diverse materials or have tight budget constraints: Carefully evaluate the suitability of your materials and weigh the upfront cost of specialized inductors against the long-term safety and operational benefits.

Choosing the right technology requires a holistic view of your process, but when it comes to operator safety, induction heating represents a fundamental step forward.

Summary Table:

| Key Safety Benefit | How It Works |

|---|---|

| Flameless Operation | Uses electromagnetic fields, eliminating ignition sources and combustion byproducts like carbon monoxide. |

| Localized Heating | Heat is generated directly within the conductive part, keeping the surrounding area and equipment cool. |

| Reduced Ambient Heat | Minimizes operator heat stress by not radiating heat into the workspace. |

| Precise Temperature Control | Digital controls prevent overheating, ensuring process repeatability and material integrity. |

Ready to enhance safety and precision in your heating processes?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, high-temperature heating solutions. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique requirements.

Contact us today to discuss how our tailored solutions can create a safer, more efficient workplace for your team. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies