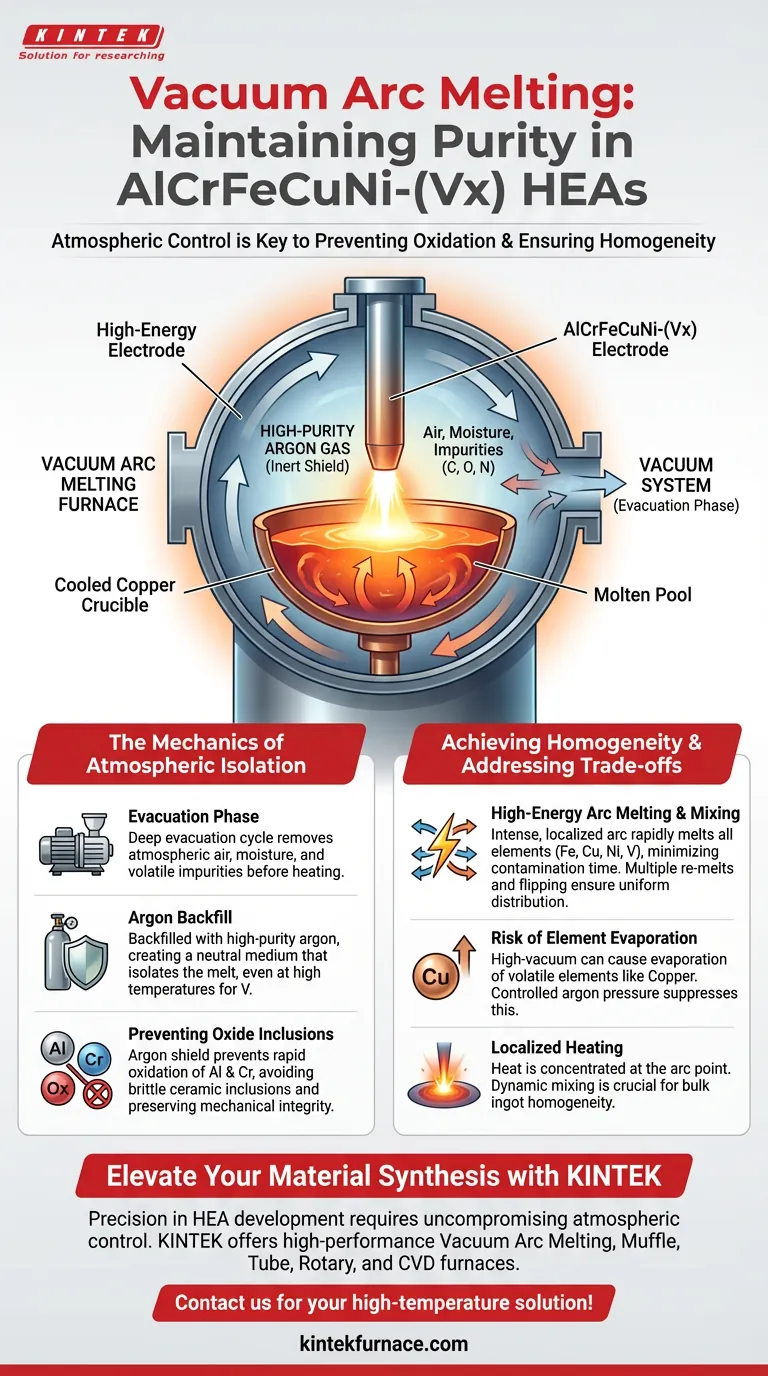

The primary mechanism for maintaining purity is strict atmospheric control. A vacuum arc melting furnace achieves this by first evacuating the chamber to remove contaminants, then backfilling it with high-purity argon gas. This creates an inert shield that isolates the molten AlCrFeCuNi-(Vx) alloy from atmospheric oxygen and nitrogen, preventing the degradation of reactive elements.

Core Takeaway Purity in vacuum arc melting is not achieved by the vacuum alone, but by the substitution of a reactive atmosphere (air) with a protective one (argon). This process is essential for preserving the stoichiometry of High-Entropy Alloys (HEAs) containing oxidation-prone elements like Aluminum, Chromium, and Vanadium.

The Mechanics of Atmospheric Isolation

The Evacuation Phase

Before heat is applied, the furnace chamber undergoes a deep evacuation cycle. This step actively removes atmospheric air, moisture, and volatile impurities from the melting zone. By lowering the pressure significantly, the system eliminates the baseline sources of carbon, oxygen, and nitrogen contamination.

The Argon Backfill

Once the vacuum is established, the chamber is backfilled with high-purity argon gas. This gas acts as a neutral medium that does not react with the metal, even at the extreme temperatures required to melt refractory elements like Vanadium. The argon pressure also suppresses the vaporization of volatile elements, ensuring the final alloy composition matches the intended design.

Preventing Oxide Inclusions

The primary threat to AlCrFeCuNi-(Vx) alloys is the rapid oxidation of Aluminum (Al) and Chromium (Cr). Without the argon shield, these elements would react with oxygen to form brittle ceramic inclusions (oxides) within the metal matrix. The controlled atmosphere ensures these elements remain in their metallic state, preserving the alloy's mechanical integrity.

Achieving Homogeneity Through Process Control

High-Energy Arc Melting

The furnace utilizes a high-current electric arc to generate intense, localized heat. This rapidly melts the constituent elements—Iron (Fe), Copper (Cu), Nickel (Ni), and the higher-melting Vanadium (V)—into a single liquid pool. The speed of melting helps minimize the time window in which contaminants could potentially interact with the melt.

Dynamic Mixing and Flipping

To ensure the purity extends to the alloy's microstructure, the process typically involves multiple melting cycles. The solidified ingot is often flipped and re-melted several times. This mechanical redistribution, combined with electromagnetic stirring forces generated by the arc, ensures a uniform distribution of elements and eliminates segregation.

Understanding the Trade-offs

The Risk of Element Evaporation

While the vacuum/argon environment prevents oxidation, high-vacuum stages can sometimes lead to the evaporation of elements with high vapor pressures (like Copper or Manganese) if not managed correctly. If the pressure drops too low during the melt, you risk altering the alloy's precise chemical ratio.

Localized vs. Bulk Heating

Unlike induction melting, which heats the entire crucible volume, arc melting heats locally at the arc impact point. While this allows for extremely high temperatures, it requires careful operator skill or automated stirring to ensure the "purity" is consistent throughout the entire volume of the ingot, rather than just the surface.

Making the Right Choice for Your Goal

When synthesizing AlCrFeCuNi-(Vx) alloys, your equipment settings must align with your specific material objectives:

- If your primary focus is Eliminating Oxides: Prioritize a high-quality pre-evacuation stage to remove all moisture before introducing the argon backfill.

- If your primary focus is Compositional Accuracy: Monitor the chamber pressure carefully to prevent the evaporation of Copper (Cu) while melting high-temperature Vanadium (V).

- If your primary focus is Microstructural Uniformity: Increase the number of flipping and re-melting cycles to ensure the five+ elements are thoroughly homogenized.

The integrity of a High-Entropy Alloy is defined by the quality of the atmosphere in which it is born.

Summary Table:

| Feature | Mechanism for Purity & Homogeneity |

|---|---|

| Atmospheric Control | Deep evacuation removes moisture/oxygen; high-purity argon prevents oxidation. |

| Oxide Prevention | Inert gas shielding protects reactive elements like Al, Cr, and V. |

| Thermal Efficiency | High-energy arc melting rapidly liquefies refractory elements like Vanadium. |

| Mixing Technique | Multiple flipping and re-melting cycles eliminate chemical segregation. |

| Compositional Integrity | Controlled pressure suppresses the vaporization of volatile elements like Copper. |

Elevate Your Material Synthesis with KINTEK

Precision in High-Entropy Alloy (HEA) development requires uncompromising atmospheric control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Arc Melting systems, Muffle, Tube, Rotary, and CVD furnaces, all customizable to your unique research or production needs.

Whether you are synthesizing complex AlCrFeCuNi-(Vx) alloys or processing refractory metals, our systems ensure the highest levels of purity and homogeneity. Contact us today to find the perfect high-temperature solution for your lab!

Visual Guide

References

- Praise Mpofu, Lehlogonolo Rudolf Kanyane. RETRACTED: Mechanical and Tribological Performance of AlCrFeCuNi-(Vx) HEAs Synthesized via Arc Melting technique. DOI: 10.1051/e3sconf/202450501015

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What safety advantages do Vacuum Induction Melting Furnaces offer? Ensure Operator and Material Safety in High-Stakes Industries

- Can an induction furnace melt steel? Achieve Fast, Clean, and Controlled Steel Melting

- How does the vacuum chamber in a vacuum casting furnace function? Unlock Purity and Performance in Metal Casting

- Why is high-purity argon gas utilized during the melting of AlCoCrFeNi2.1 alloys? Ensure Peak Alloy Purity

- What is the primary role of a vacuum induction furnace for TWIP steel? Ensure Purity and Chemical Precision

- What are the key components of an induction-heated vacuum furnace? Uncover the Systems for Pure Melting

- What is an induction furnace and how does it operate? A Guide to Clean, Efficient Metal Melting

- What is induction melting and how is it used in industries? Discover its key benefits for metal processing.