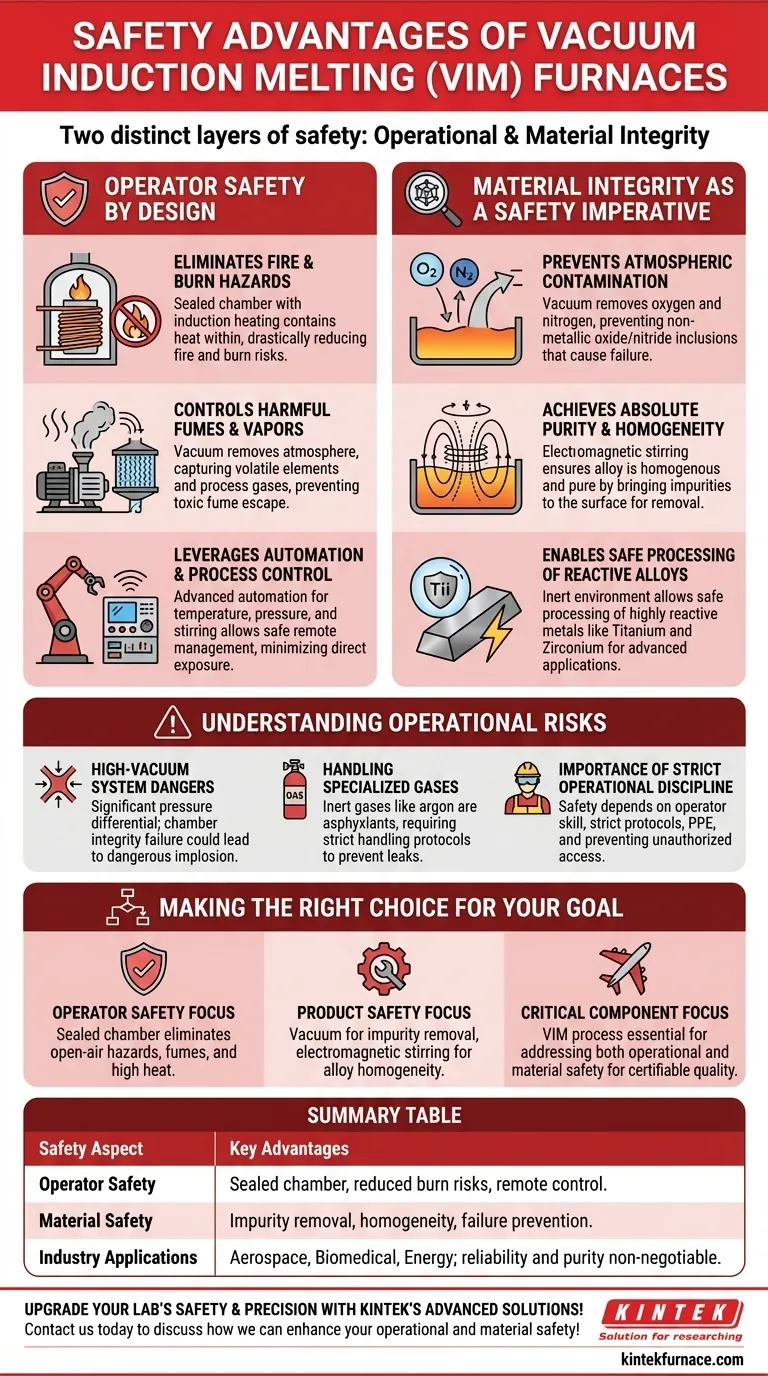

To be direct, a Vacuum Induction Melting (VIM) furnace offers two distinct layers of safety. The first is operational safety, protecting personnel by containing the high-temperature process in a sealed, controlled environment free of open flames and toxic fumes. The second, and often more critical advantage, is material safety—the furnace's ability to produce exceptionally pure, uniform, and reliable alloys, which is essential for components where failure is not an option.

The core safety benefit of a VIM furnace is its ability to control the environment on both a macro and micro level. It creates a safer workshop for the operator while simultaneously creating a fundamentally safer, more reliable material by eliminating the internal impurities and inconsistencies that cause catastrophic failure.

Operator Safety by Design

The inherent design of a VIM furnace eliminates many of the traditional dangers associated with metal melting. It builds safety into the process itself, rather than relying solely on operator procedure.

Eliminating Fire and Burn Hazards

A VIM furnace operates as a sealed chamber. Unlike conventional methods, it uses induction heating, which generates heat directly within the metal itself without any open flames or external heating elements.

This design drastically reduces the risk of fires and operator burns, as the most intense heat is contained entirely within the furnace's crucible.

Controlling Harmful Fumes and Vapors

The vacuum environment is fundamental to VIM safety. By removing the atmosphere, the system can capture and safely manage harmful volatile elements and process gases.

This prevents toxic fumes from escaping into the workshop, protecting operators from exposure to substances that are common in traditional air-melting processes.

Leveraging Automation and Process Control

Modern VIM systems feature advanced automation for controlling temperature, pressure, and stirring. This allows operators to manage the melting process from a safe distance, minimizing direct exposure to the equipment during its most critical phases.

Material Integrity as a Safety Imperative

For industries like aerospace, biomedical, and energy, the "safety" of the final product is paramount. The VIM process is designed to produce materials with predictable, reliable properties, making it a cornerstone of manufacturing for critical applications.

Preventing Atmospheric Contamination

The primary purpose of the vacuum is to remove atmospheric gases like oxygen and nitrogen. These elements cause the formation of non-metallic oxide and nitride inclusions in the molten metal.

These inclusions act as microscopic weak points in the final alloy, creating stress risers that can lead to premature cracks and material failure. A VIM furnace produces a cleaner, stronger, and therefore safer, material.

Achieving Absolute Purity and Homogeneity

The electromagnetic field that heats the metal also induces a powerful, consistent stirring action throughout the molten bath.

This stirring ensures the alloy is perfectly homogenous, preventing the segregation of different elements. It also helps bring dissolved gases and trace impurities to the surface, where the vacuum can remove them, resulting in an exceptionally pure final product.

Enabling the Safe Processing of Reactive Alloys

Metals like titanium and zirconium are highly reactive with oxygen, making them extremely difficult or impossible to melt in open air.

The inert, controlled environment of a VIM furnace is the only way to safely process these materials, unlocking their use in advanced, high-performance applications.

Understanding the Operational Risks

While inherently safer in many ways, VIM furnaces are complex systems that introduce their own set of hazards. True safety relies on understanding and mitigating these specific risks.

The Dangers of High-Vacuum Systems

The furnace operates under a powerful vacuum, creating a significant pressure differential. Any failure in the chamber's structural integrity could lead to a dangerous implosion event.

Handling of Specialized Gases

VIM processes often use inert gases like argon to backfill the chamber. While not toxic, these gases are asphyxiants and require strict handling protocols to prevent leaks and ensure proper ventilation in the facility.

The Importance of Strict Operational Discipline

The safety of a VIM system is ultimately dependent on the skill of its operators. Adhering to strict safety protocols, wearing proper personal protective equipment (PPE), and preventing unauthorized access are non-negotiable requirements for safe operation.

Making the Right Choice for Your Goal

To select and operate a VIM furnace effectively, you must align its capabilities with your primary safety objective.

- If your primary focus is operator safety and environmental compliance: The key advantage is the sealed chamber, which contains fumes, vapors, and high heat, eliminating the open-air hazards of conventional melting.

- If your primary focus is product safety and material reliability: The crucial features are the vacuum for removing impurities and the electromagnetic stirring for ensuring complete alloy homogeneity, which together prevent internal points of failure.

- If your primary focus is producing critical components for high-stakes industries: The VIM process is essential, as it is the only method that systematically addresses both operational and material safety to produce materials of certifiable quality.

Ultimately, the defining safety advantage of a VIM furnace is its ability to create certainty—both in the workshop and within the atomic structure of the final product.

Summary Table:

| Safety Aspect | Key Advantages |

|---|---|

| Operator Safety | Sealed chamber eliminates open flames, toxic fumes, and reduces burn risks; automation allows remote control. |

| Material Safety | Vacuum removes impurities, electromagnetic stirring ensures homogeneity, preventing failures in critical alloys. |

| Industry Applications | Essential for aerospace, biomedical, and energy where material reliability and purity are non-negotiable. |

Upgrade your lab's safety and precision with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our deep customization capabilities ensure you get reliable, pure materials for critical applications. Contact us today to discuss how we can enhance your operational and material safety!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing