At its core, an induction-heated vacuum furnace combines several critical components to melt materials in a highly controlled, contamination-free environment. The key elements are the power supply, induction coil, crucible, vacuum chamber, and the vacuum pump system, all managed by an integrated electrical control system.

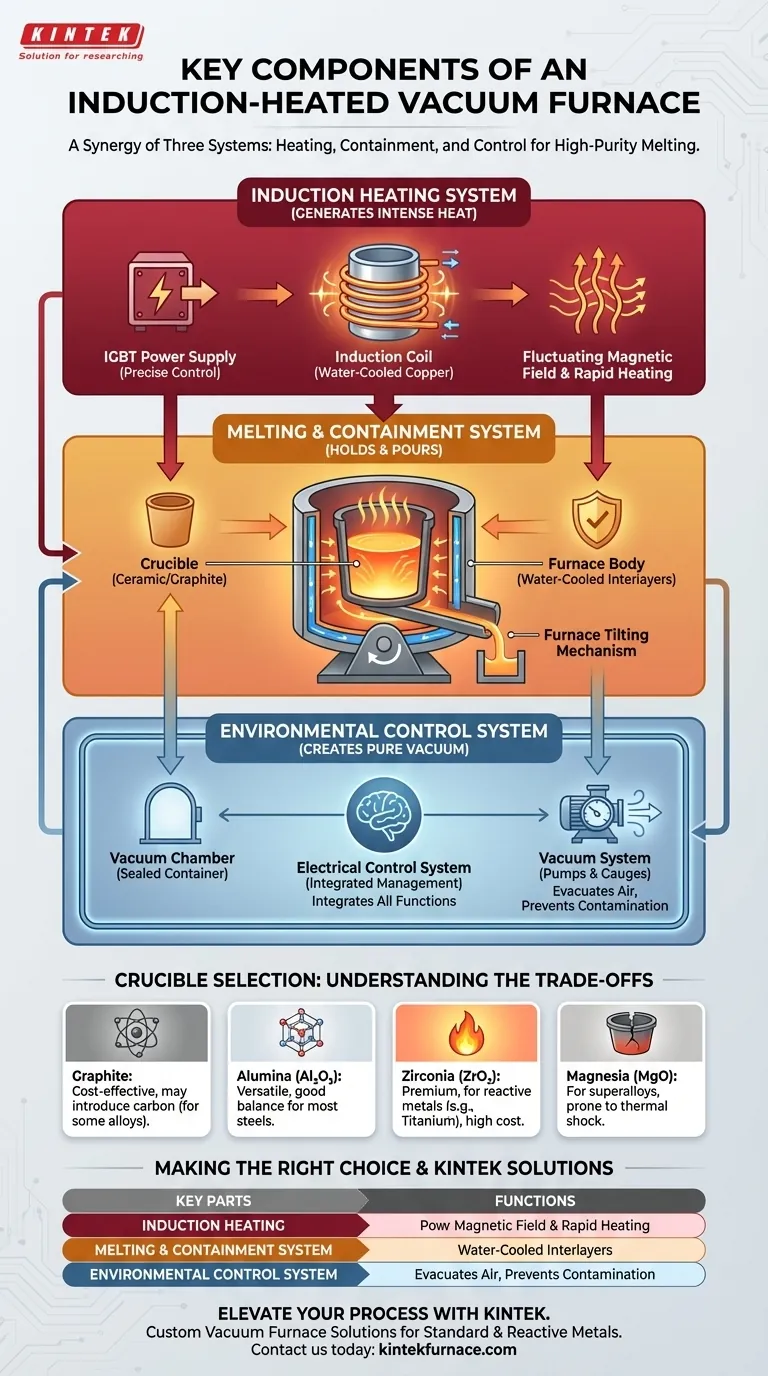

A vacuum induction furnace is not just a collection of parts, but a synergy of three distinct systems working in unison: one to generate intense heat, one to contain the molten material, and one to create a pure, controlled atmosphere. Understanding how these systems interact is key to mastering the process.

The Core Systems of a Vacuum Induction Furnace

A vacuum induction furnace operates by integrating three primary functions. Each component plays a specific role in either generating heat, containing the melt, or controlling the environment.

The Induction Heating System

This system is responsible for generating and delivering the energy required to melt the metal.

- Medium Frequency Power Supply: This is the heart of the heating system, converting standard electrical power into the high-current, medium-frequency power needed for induction. Modern systems often use IGBT (Insulated Gate Bipolar Transistor) technology for precise control and efficiency.

- Induction Coil: A coil of water-cooled copper tubing is positioned around the crucible. The high-frequency current from the power supply flows through this coil, generating a powerful and fluctuating magnetic field. This field induces strong electrical currents directly within the metal charge, causing it to heat rapidly and melt from the inside out.

The Melting and Containment System

This physical structure contains the intense heat and the molten metal, ensuring structural integrity and safe operation.

- Crucible: The crucible is the ceramic or graphite pot that holds the metal charge. It must withstand extreme temperatures and be chemically inert to the molten metal to prevent contamination.

- Furnace Body: The main structure houses the crucible and coil. It is built with water-cooled interlayers to absorb the immense radiant heat, protecting the external structure and internal components from damage.

- Furnace Tilting Mechanism: For pouring, the entire furnace assembly is typically mounted on a mechanism that allows it to be tilted, ensuring a controlled and safe transfer of the molten metal into a mold.

The Environmental Control System

This system creates the vacuum necessary for producing high-purity metals and alloys.

- Vacuum Chamber: This is a sealed, robust container that encloses the crucible and induction coil. It is designed to withstand both high internal temperatures and the external pressure of the atmosphere when a vacuum is pulled.

- Vacuum System: This consists of a series of pumps and gauges. The pumps evacuate air and other gases from the chamber to create the vacuum, preventing the molten metal from reacting with oxygen and nitrogen. Gauges precisely measure the vacuum level.

- Electrical Control System: This is the brain of the furnace. It integrates and manages all other components, from the power output of the supply and the vacuum level to the furnace's tilting motion and safety interlocks.

Understanding the Trade-offs: Crucible Selection

The choice of crucible material is one of the most critical decisions, as it directly impacts the purity and quality of the final product. The wrong material can react with the molten metal or fail under thermal stress.

Graphite Crucibles

Graphite is a common and cost-effective choice. However, it can introduce carbon into the melt, which is undesirable for certain low-carbon steels and alloys as it can form brittle carbides.

Alumina (Al₂O₃) Crucibles

Alumina is a versatile, all-purpose material suitable for melting most steels, nickel-based alloys, and cobalt-based alloys. It offers a good balance of thermal stability and chemical resistance.

Zirconia (ZrO₂) Crucibles

Zirconia is the premium choice for melting highly reactive metals like titanium or superalloys at very high temperatures. It is more stable and less reactive than alumina but comes at a significantly higher cost.

Magnesia (MgO) Crucibles

Magnesia is used for melting certain nickel or cobalt-based superalloys. Its primary drawback is a higher susceptibility to thermal shock, which can lead to cracking if heated or cooled too quickly.

Making the Right Choice for Your Goal

Selecting the right components depends entirely on the material you are processing and your desired outcome.

- If your primary focus is melting standard steels and non-reactive alloys: An alumina crucible paired with a reliable IGBT power supply offers the best balance of performance and cost.

- If your primary focus is processing high-purity, reactive metals (e.g., titanium): A high-performance vacuum system and a zirconia crucible are non-negotiable to prevent contamination and ensure metallurgical quality.

- If your primary focus is operational efficiency and process repeatability: An integrated electrical control system is essential for precise management of heating cycles, vacuum levels, and safety protocols.

Understanding how each component contributes to the final result empowers you to design a process that delivers consistent, high-quality material every time.

Summary Table:

| Component System | Key Parts | Primary Function |

|---|---|---|

| Induction Heating | Power Supply, Induction Coil | Generate intense heat via electromagnetic induction |

| Melting and Containment | Crucible, Furnace Body, Tilting Mechanism | Hold and pour molten metal safely |

| Environmental Control | Vacuum Chamber, Vacuum System, Electrical Control | Create and manage vacuum for purity and safety |

Ready to elevate your metal processing with a custom vacuum furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces tailored to your needs. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're melting standard alloys or reactive metals, our expertise ensures optimal performance and purity. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys