At its core, an induction furnace is a specialized electric furnace that melts conductive metals without any direct contact or flames. It achieves this by using the principle of electromagnetic induction, where a powerful, fluctuating magnetic field generates intense heat directly within the metal itself.

The central concept to grasp is that an induction furnace operates like a powerful electrical transformer. The furnace's copper coil acts as the primary winding, and the metal placed inside becomes a short-circuited secondary winding, heating itself from within due to its own electrical resistance.

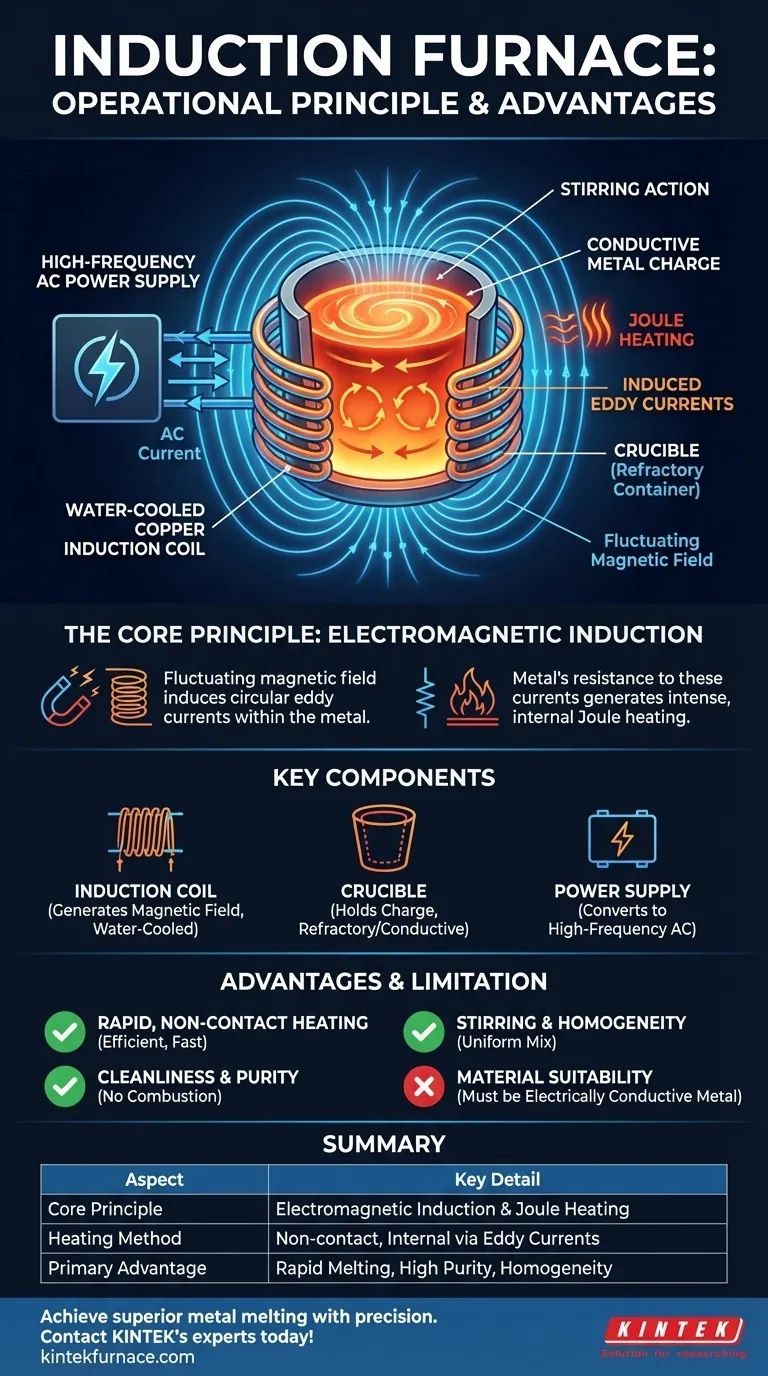

The Core Principle: Electromagnetic Induction

The operation of an induction furnace is a direct application of fundamental physics. It’s a clean, contained, and highly controllable process that relies on a sequence of events triggered by an alternating current.

The Role of Alternating Current (AC)

The entire process begins with a high-frequency alternating current (AC). This is non-negotiable; a direct current (DC) would not work because it produces a static magnetic field.

Only the constantly reversing flow of AC can create the changing magnetic field required to induce a current in the metal charge.

Generating the Magnetic Field

The AC is passed through a primary inductor, which is typically a multi-turn coil of water-cooled copper tubing. This coil is shaped to surround a crucible containing the metal to be melted.

As the powerful AC flows through this coil, it generates a strong and rapidly fluctuating magnetic field in the space within and around the coil.

Inducing Eddy Currents

This fluctuating magnetic field penetrates the conductive metal (the "charge") placed inside the crucible. According to Faraday's Law of Induction, this changing magnetic field induces circular electrical currents within the metal.

These induced currents are known as eddy currents.

Heating Through Resistance

The metal itself has a natural resistance to the flow of these eddy currents. This resistance creates friction on an atomic level, which generates immense heat—a phenomenon known as Joule heating.

This internally generated heat rapidly raises the metal's temperature to its melting point and beyond, all without any external heat source touching the material.

Key Components of an Induction Furnace

An induction furnace is a system of a few critical components working in concert.

The Induction Coil

This is the heart of the furnace. It's the copper coil that receives the electrical energy and generates the magnetic field. It must be water-cooled to dissipate the significant heat generated by the high currents passing through it.

The Crucible

This is the refractory container that holds the metal charge. The crucible material is chosen based on the application.

If the crucible is made of a non-conductive ceramic, the magnetic field passes through it to heat the metal charge directly. If it's made of a conductive material like graphite, the crucible itself is also heated by induction, transferring some of that heat to the charge.

The Power Supply

A specialized power unit is required to take standard utility power and convert it into the high-frequency alternating current needed to drive the induction coil efficiently.

Understanding the Advantages and Trade-offs

Induction melting offers distinct benefits but is not a universal solution. Understanding its characteristics is key to appreciating its value.

Advantage: Rapid, Non-Contact Heating

Because heat is generated within the metal, the process is extremely fast and efficient. There is no need to heat a chamber or wait for thermal transfer from an external element, which minimizes energy loss.

Advantage: Stirring and Homogeneity

The same magnetic forces that induce the eddy currents also create a vigorous stirring action within the molten metal. This ensures that alloying elements are mixed thoroughly, resulting in a highly uniform and consistent final product.

Advantage: Cleanliness and Purity

Since there is no combustion of fuel, the process is exceptionally clean. This eliminates a major source of contamination, making induction furnaces ideal for producing high-purity alloys and specialty metals.

Limitation: Material Suitability

The primary requirement for induction heating is that the material must be electrically conductive. It is a highly effective method for metals like steel, copper, aluminum, and precious metals but cannot be used to directly heat non-conductive materials like ceramics or glass.

Making the Right Choice for Your Goal

Selecting the right melting technology depends entirely on your operational priorities.

- If your primary focus is alloy quality and purity: Induction is superior due to its inherent stirring action and lack of combustion byproducts, ensuring a clean and homogenous melt.

- If your primary focus is speed and on-demand melting: The rapid, internal heating of induction furnaces makes them ideal for applications requiring fast startups and quick batch turnaround.

- If your primary focus is operational efficiency and control: Induction offers precise temperature control and high energy efficiency because the heat is generated exactly where it is needed—inside the metal itself.

By harnessing electromagnetic forces, induction furnaces provide a powerful, clean, and highly controlled method for melting metals.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Core Principle | Electromagnetic Induction & Joule Heating |

| Heating Method | Non-contact, internal heating via induced eddy currents |

| Key Components | Induction Coil, Crucible, High-Frequency Power Supply |

| Primary Advantage | Rapid melting, excellent homogeneity, high purity, precise control |

| Material Suitability | Electrically conductive metals (e.g., steel, copper, aluminum) |

Ready to achieve superior metal melting with precision and purity? KINTEK's advanced induction furnace solutions leverage our exceptional R&D and in-house manufacturing to deliver the performance your laboratory needs. Whether you require a standard system or a deeply customized furnace for unique experimental requirements, our expertise in Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD systems ensures we have the right solution for you. Contact our experts today to discuss how we can optimize your melting process!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control