Vacuum Induction Melting & Casting (VIM&C) is the manufacturing process of choice for creating the most advanced and reliable metal components in existence. It is the go-to method for critical applications in aerospace, medical, and nuclear industries, where material failure can have catastrophic consequences. The process is used to produce everything from jet engine turbine blades and medical implants to nuclear reactor components and high-purity semiconductor materials.

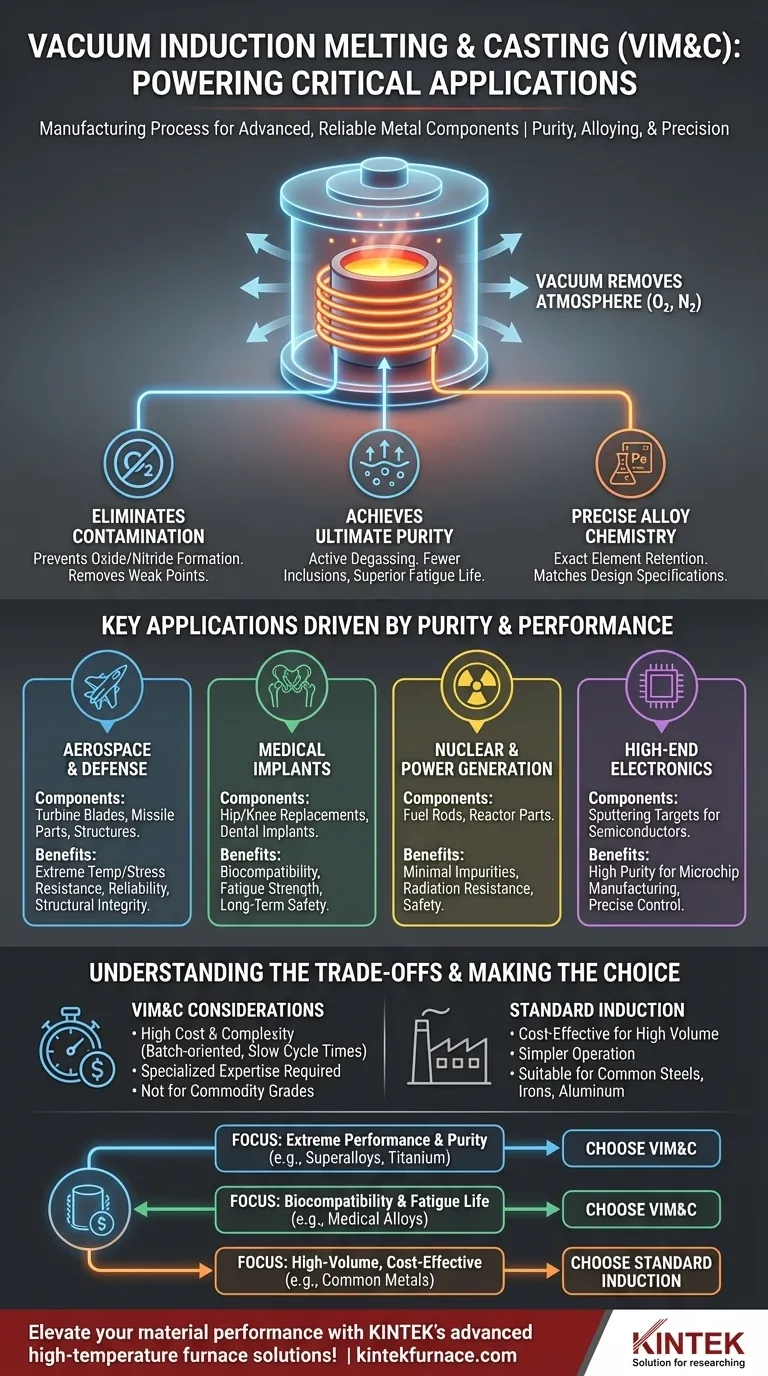

At its core, VIM&C is not simply about melting metal. It is a purification and alloying process that uses a vacuum to remove atmospheric gases like oxygen and nitrogen, which are the primary sources of contamination and weakness in high-performance alloys. This precise control over purity and chemistry is what enables the creation of materials with exceptional strength, cleanliness, and reliability.

Why a Vacuum is the Critical Component

The "vacuum" in VIM&C is what separates it from standard induction melting. Removing the atmosphere from the melting chamber fundamentally changes what is possible in metallurgy.

Eliminating Atmospheric Contamination

Standard air is roughly 78% nitrogen and 21% oxygen. When reactive metals like titanium or superalloys are melted in the open air, these gases dissolve into the molten metal, forming oxides and nitrides that create weak points and lead to premature failure.

A vacuum environment removes these reactive gases, preventing the formation of these impurities and ensuring the final material is as strong and clean as theoretically possible.

Achieving Ultimate Purity

Beyond preventing new contamination, the vacuum actively pulls dissolved gases and other volatile impurities out of the molten metal. This "degassing" step is crucial for producing ultra-clean materials.

The result is a metal with significantly fewer non-metallic inclusions, leading to superior fatigue life, toughness, and overall performance.

Precise Control Over Alloy Chemistry

Many advanced alloys contain elements that have a high vapor pressure or react readily with air. The vacuum allows for the precise addition and retention of these sensitive alloying elements.

This ensures the final chemistry matches the design specification exactly, which is essential for achieving the desired mechanical properties and performance characteristics.

Key Applications Driven by Purity and Performance

The unique capabilities of VIM&C make it indispensable for industries that rely on materials operating at the limits of their performance.

Aerospace and Defense

Components like aircraft engine turbine blades, missile parts, and satellite structures are made from nickel-based superalloys. These parts must withstand extreme temperatures and mechanical stress.

VIM&C is the only process that can produce superalloys with the required purity and structural integrity to operate safely and reliably in these environments.

Medical Implants

Materials used inside the human body, such as hip and knee replacements or dental implants, must be perfectly biocompatible and possess exceptional fatigue strength. These are often made from titanium or specialized stainless steels.

The VIM&C process removes impurities that could cause an adverse reaction in the body and ensures the implant has the flawless internal structure needed to last for decades without failing.

Nuclear and Power Generation

The nuclear industry demands materials with predictable behavior and extreme reliability for components like fuel rods and reactor parts.

VIM&C provides the necessary control to produce alloys with minimal impurities, which is critical for ensuring safety and long-term performance under radiation. This same need for high-purity materials extends to manufacturing components for solar cells and semiconductors.

High-End Electronics

The production of semiconductors and electronic devices often requires extremely pure metals for processes like physical vapor deposition.

VIM&C is used to create the high-purity sputtering targets that are essential for manufacturing microchips and other advanced electronic components.

Understanding the Trade-offs

While VIM&C delivers unparalleled quality, it is a specialized process with specific constraints.

The Cost Factor

VIM&C is a batch-oriented and relatively slow process. The specialized vacuum furnaces, complex controls, and longer cycle times make it significantly more expensive than conventional melting techniques.

Because of this, it is reserved for applications where the high cost is justified by the absolute need for material performance and reliability.

Complexity and Scale

Operating a VIM&C facility requires significant technical expertise. The process is not suited for producing high-volume, commodity-grade metals.

Its strength lies in producing smaller, highly controlled batches of specialized, high-value alloys.

When Simpler Induction Melting is Enough

For many applications, such as casting standard steel, iron, or aluminum parts for the automotive or general manufacturing sectors, the extreme purity of VIM&C is unnecessary.

In these cases, a standard induction furnace operating in air or under an inert gas blanket provides a much more cost-effective solution for producing quality parts where minor atmospheric contamination is not a critical failure point.

Making the Right Choice for Your Goal

Selecting a melting process requires matching the technology to the material's end-use requirements.

- If your primary focus is extreme performance and purity: VIM&C is the non-negotiable standard for producing superalloys, titanium alloys, and other reactive metals for critical applications.

- If your primary focus is biocompatibility and fatigue life: VIM&C is essential for manufacturing medical-grade alloys to ensure safety and long-term reliability inside the body.

- If your primary focus is high-volume, cost-effective production: A standard air-melt induction furnace is the more practical and economical choice for most common steels, irons, and aluminum alloys.

Ultimately, choosing VIM&C is a decision to prioritize material perfection over production cost, a trade-off required for the world's most demanding technologies.

Summary Table:

| Application Area | Key Components Produced | Primary Benefits |

|---|---|---|

| Aerospace and Defense | Jet engine turbine blades, missile parts | Extreme temperature resistance, high strength, reliability |

| Medical Implants | Hip and knee replacements, dental implants | Biocompatibility, fatigue strength, long-term safety |

| Nuclear and Power Generation | Fuel rods, reactor components | Minimal impurities, radiation resistance, safety |

| High-End Electronics | Sputtering targets for semiconductors | High purity for microchip manufacturing, precise alloy control |

Elevate your material performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored VIM&C systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering unparalleled purity and reliability for critical applications in aerospace, medical, nuclear, and electronics industries. Contact us today to discuss how we can optimize your melting and casting processes for superior results!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production