In short, vacuum smelting was the essential breakthrough that enabled the creation of modern, high-performance superalloys. By removing atmospheric gases during melting, it allowed metallurgists to design and produce alloys with higher strength, greater purity, and the ability to withstand extreme temperatures—properties that were previously unattainable.

The core challenge in superalloy design is that the most critical strengthening elements, like titanium and aluminum, are highly reactive with oxygen and nitrogen in the air. Vacuum smelting solves this by creating a protected environment, preventing contamination and unlocking the full potential of the alloy's chemistry.

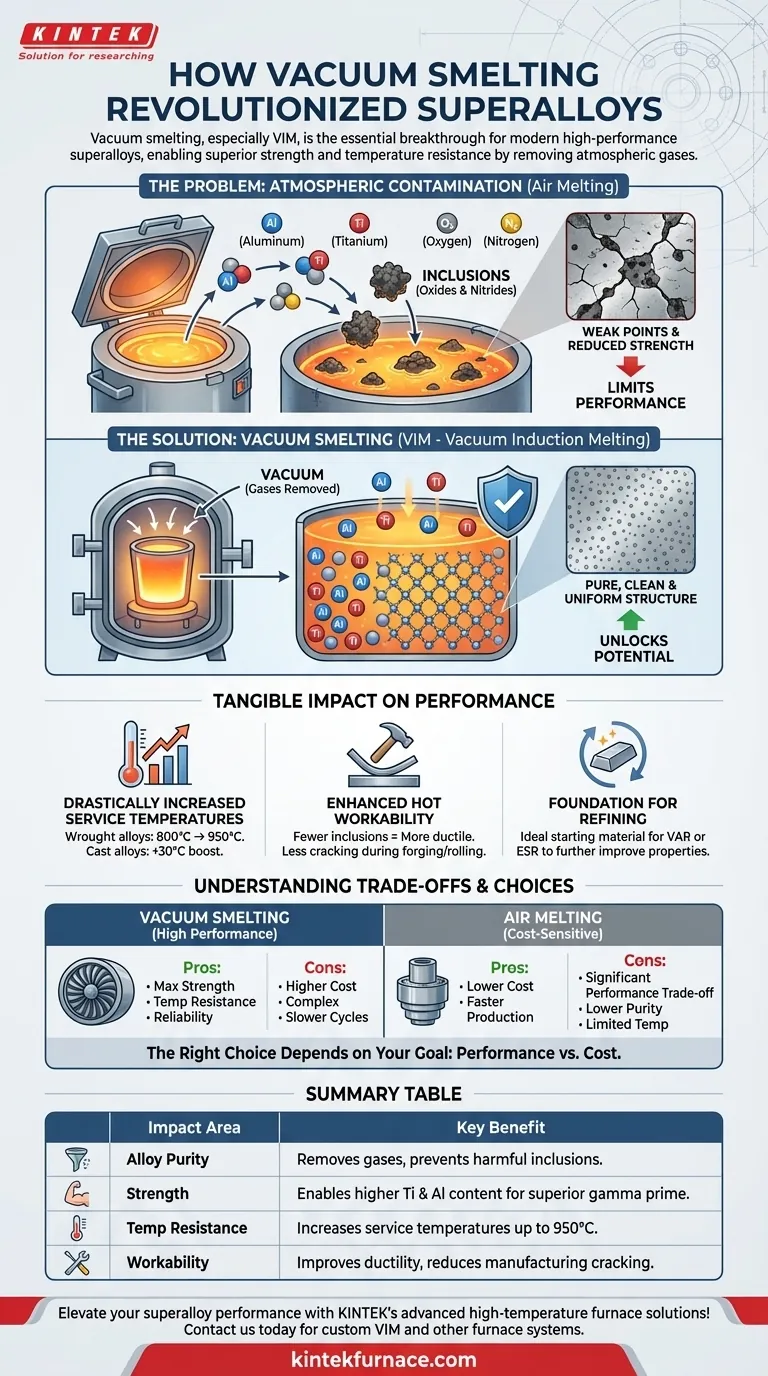

The Core Problem: Atmospheric Contamination

Before the widespread adoption of vacuum processing, superalloy development faced a fundamental limit. The very act of melting the metals in air was degrading their potential performance.

The Critical Role of Reactive Elements

Superalloys derive their incredible high-temperature strength from the precise formation of internal microstructures, primarily the gamma prime (γ') phase. This phase is formed by specific alloying elements, most notably aluminum (Al) and titanium (Ti).

The more Al and Ti you can successfully add to the nickel-based alloy, the stronger and more temperature-resistant it becomes.

The Formation of Harmful Inclusions

When melted in the presence of air, these highly reactive elements (Al, Ti) instantly bond with oxygen and nitrogen. This forms non-metallic inclusions like oxides and nitrides.

These tiny, brittle particles get trapped in the final metal. They act as microscopic weak points, reducing ductility, initiating cracks, and severely limiting the material's fatigue life and overall strength.

How Vacuum Smelting Provides the Solution

Vacuum smelting, particularly Vacuum Induction Melting (VIM), directly addresses the contamination problem. By placing the entire melting process inside a vacuum chamber, it fundamentally changes what is possible.

Preventing Oxidation and Nitridation

The most direct benefit of the vacuum is the removal of reactive gases. With virtually no oxygen or nitrogen present, the aluminum and titanium remain free to perform their intended function: strengthening the alloy.

Enabling Higher Alloy Content

Because the reactive elements are protected from contamination, metallurgists can confidently add them in much higher concentrations. This directly leads to a greater volume of the strengthening gamma prime phase, pushing the boundaries of material performance.

Improving Material Purity and Cleanliness

The vacuum environment also helps to remove other dissolved gases from the molten metal, resulting in a "cleaner" and more uniform final product. This inherent purity significantly improves the alloy's properties.

The Tangible Impact on Superalloy Performance

The shift to vacuum processing was not an incremental improvement; it was a revolutionary step that redefined the capabilities of superalloys.

Drastically Increased Service Temperatures

The ability to create cleaner, more highly-alloyed materials had a direct impact on how hot they could operate. For wrought (deformed) superalloys, vacuum processing raised maximum service temperatures from around 800°C to 950°C.

Even for advanced cast superalloys, the move to vacuum techniques provided an additional performance boost of approximately 30°C.

Enhanced Hot Workability

A cleaner alloy with fewer brittle inclusions is more ductile and forgiving during manufacturing. This enhanced hot workability means the material is less likely to crack during forging, rolling, or other shaping processes, leading to better yields and more reliable components.

A Foundation for Further Refining

VIM is often the critical first step in a multi-stage process for the most demanding applications. The high-purity ingots produced by VIM serve as the ideal starting material for secondary refining processes like Vacuum Arc Remelting (VAR) or Electroslag Remelting (ESR), which further improve the material's structure and properties.

Understanding the Trade-offs

While its benefits are undeniable, vacuum processing is a more demanding manufacturing route.

Increased Cost and Complexity

Vacuum furnaces are significantly more expensive to build, operate, and maintain than air-melt furnaces. The process requires complex vacuum systems and precise controls, adding to the overall cost of the final material.

Slower Production Cycles

Each melting cycle requires time to pump the chamber down to the required vacuum level. This makes the process inherently slower than continuous or batch melting in air, impacting throughput and cost.

Making the Right Choice for Your Goal

Understanding the impact of vacuum smelting helps in specifying the right material for a given application.

- If your primary focus is maximum performance and reliability (e.g., jet engine turbine blades, power generation): Vacuum-processed superalloys are non-negotiable. The protection they offer is the only way to achieve the required strength and temperature resistance.

- If your primary focus is a less demanding, cost-sensitive application: An air-melted alloy might be considered, but you must accept the significant trade-off in performance, purity, and temperature capability.

Ultimately, vacuum smelting transformed superalloys from high-performance materials into the extreme-environment solutions that power our modern world.

Summary Table:

| Impact Area | Key Benefit |

|---|---|

| Alloy Purity | Removes gases and prevents harmful inclusions for cleaner materials |

| Strength | Enables higher titanium and aluminum content for superior gamma prime phase |

| Temperature Resistance | Increases service temperatures up to 950°C for extreme environments |

| Workability | Improves ductility and reduces cracking during manufacturing processes |

Elevate your superalloy performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with custom Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions for your unique experimental needs, helping you achieve breakthrough results in material development. Contact us today to discuss how our expertise can benefit your projects!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance