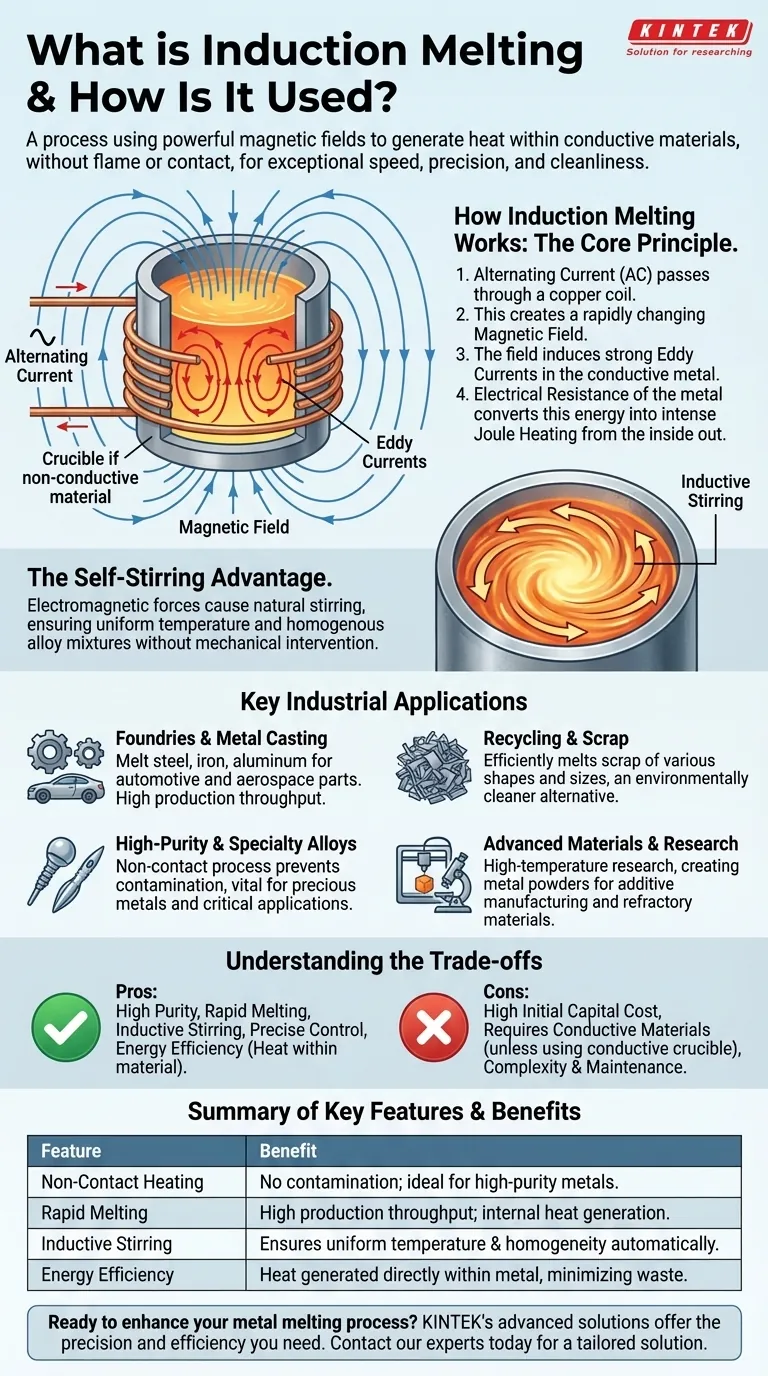

At its core, induction melting is a process that uses powerful magnetic fields to generate heat directly within a conductive material, melting it without any flame or physical contact. Industries from steel foundries to advanced research labs utilize this method for its exceptional speed, precision, and cleanliness when melting metals like iron, steel, aluminum, and precious alloys.

The true power of induction melting lies not just in its ability to heat, but in its ability to do so cleanly, quickly, and with an inherent self-stirring action. This combination provides unparalleled control over the final material's quality and chemical consistency.

How Induction Melting Works: The Core Principle

To understand its value, we must first look at the elegant physics behind the process. It's a non-contact method that turns the metal itself into the source of heat.

Creating Heat from Magnetism

An induction furnace uses a coil of copper tubing through which a high-frequency alternating current (AC) is passed. This current generates a powerful and rapidly changing magnetic field around and within the coil.

When a conductive metal is placed inside this magnetic field, the field induces strong electrical currents, known as eddy currents, to flow within the metal.

The Role of Electrical Resistance

The metal has a natural resistance to the flow of these eddy currents. This resistance converts the electrical energy into intense heat, a principle known as Joule heating.

Because the heat is generated inside the material, melting is extremely fast and efficient, with very little energy wasted to the surrounding environment.

The Self-Stirring Advantage

The same electromagnetic forces that create the eddy currents also exert a physical force on the molten metal. This causes a constant, natural stirring action throughout the molten bath.

This inductive stirring is a critical benefit, as it ensures a uniform temperature and a homogenous mixture when creating alloys, eliminating the need for separate mechanical stirring.

Key Industrial Applications

The unique characteristics of induction melting make it indispensable across a wide range of sectors. It is chosen when purity, speed, and consistency are paramount.

Foundries and Metal Casting

This is the most common application. Induction furnaces are used to melt steel, iron, and aluminum for casting into parts for the automotive, aerospace, and manufacturing industries. The process's speed allows for high production throughput.

Recycling and Scrap Metal Processing

Induction is highly effective for melting down scrap metal. Its ability to quickly melt materials of various shapes and sizes makes it an efficient and environmentally cleaner alternative to traditional fossil fuel furnaces.

High-Purity and Specialty Alloys

For industries like aerospace, medical implants, and precious metals, preventing contamination is critical. Because induction is a non-contact process, there is no contamination from burning fuel or electrodes, resulting in exceptionally pure metals and alloys.

Advanced Materials and Research

Induction melting is used in high-temperature research to study material properties and to produce highly specialized materials. This includes creating metal powders for 3D printing (additive manufacturing) and melting refractory materials that have extremely high melting points.

Understanding the Trade-offs

While powerful, induction melting is not the universal solution for every heating application. Objective analysis requires understanding its limitations.

High Initial Capital Cost

Induction furnaces and their associated power supplies represent a significant upfront investment compared to simpler, conventional fuel-fired furnaces. The technology is sophisticated and requires specialized infrastructure.

Requirement for Conductive Materials

The fundamental principle of induction heating relies on electrical conductivity. Therefore, this method is not suitable for directly melting non-conductive materials like glass or ceramics, unless a conductive crucible is used to indirectly transfer the heat.

Complexity and Maintenance

The high-frequency power supplies and water-cooled coils are complex systems that require skilled technicians for maintenance and repair. This can be a consideration for facilities in remote locations or without access to specialized labor.

Making the Right Choice for Your Goal

Selecting a melting technology depends entirely on your project's priorities, balancing cost against performance and quality.

- If your primary focus is high-purity and quality control: The clean, non-contact heating and self-stirring action make induction the superior choice for specialty alloys and precious metals.

- If your primary focus is speed and production efficiency: Induction's rapid heating cycles and precise temperature control are ideal for high-volume casting and recycling operations.

- If your primary focus is cost-sensitive bulk melting: While operationally efficient, the high initial investment may lead you to evaluate traditional fuel-fired furnaces for less demanding applications.

Ultimately, adopting induction melting is a strategic decision that prioritizes material quality, process control, and operational speed.

Summary Table:

| Feature | Benefit |

|---|---|

| Non-Contact Heating | No contamination from fuel or electrodes; ideal for high-purity metals. |

| Rapid Melting | High production throughput due to internal heat generation. |

| Inductive Stirring | Ensures uniform temperature and chemical homogeneity automatically. |

| Energy Efficiency | Heat is generated directly within the metal, minimizing waste. |

Ready to enhance your metal melting process with precision and efficiency?

KINTEK's advanced high-temperature furnace solutions, including our robust induction melting systems, are engineered to meet the demanding requirements of foundries, recyclers, and specialty alloy producers. Leveraging exceptional R&D and in-house manufacturing, we provide the clean, fast, and controlled heating you need for superior results.

Contact our experts today to discuss how our deep customization capabilities can tailor a solution for your unique operational goals.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- How is Vacuum Hot Press equipment used in R&D? Innovate with High-Purity Materials

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What are the main applications of vacuum hot pressing? Create Dense, Pure Materials for Demanding Industries