At its core, an IGBT Vacuum Induction Melting (VIM) furnace provides an exceptionally clean and controlled environment for melting metals. This technology moves beyond simple heating by using electromagnetic forces and a vacuum to eliminate atmospheric contamination, resulting in superior metal purity, precise alloy compositions, and enhanced material properties that are impossible to achieve with traditional air-melting methods.

The fundamental advantage of a VIM furnace is not just melting metal, but achieving metallurgical perfection. By removing the air, you remove the primary sources of contamination—oxygen and nitrogen—enabling the production of the highest-purity alloys and reactive metals.

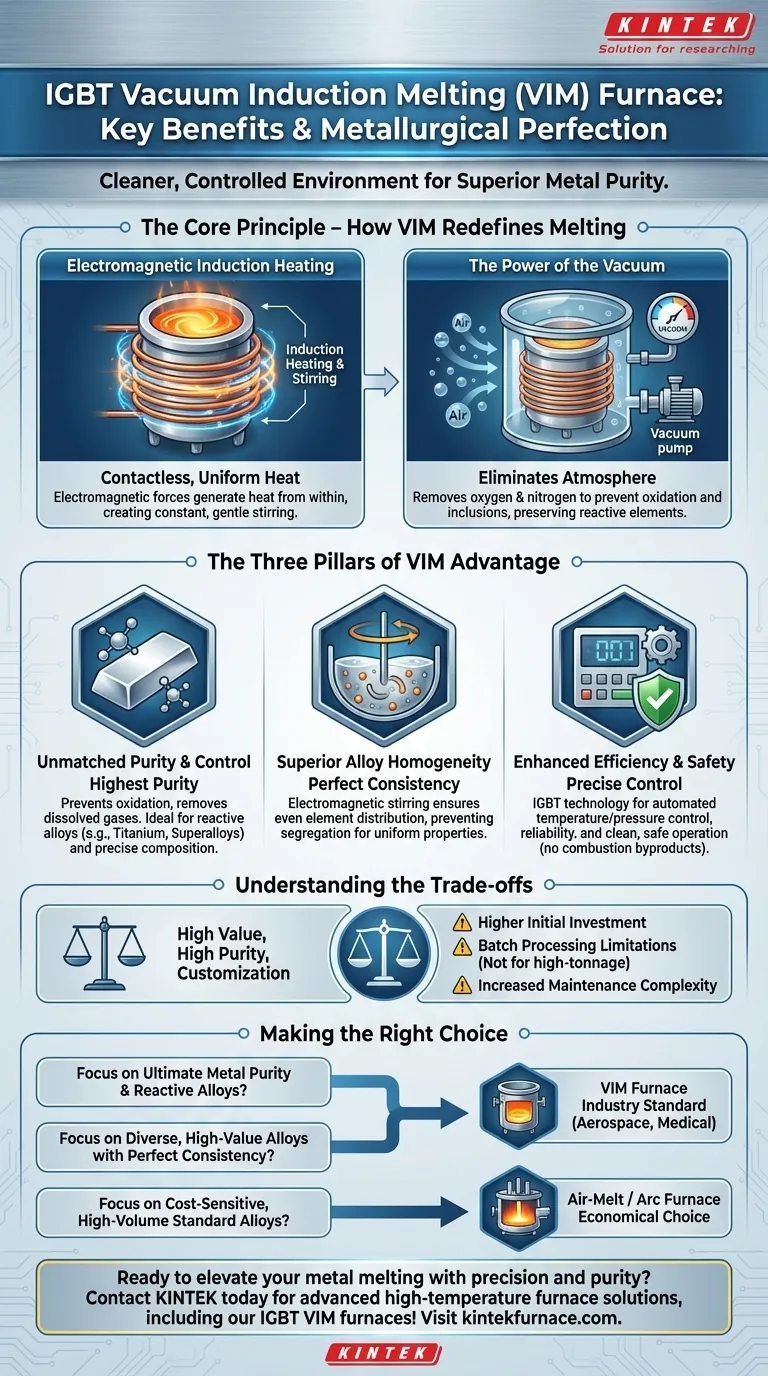

The Core Principle: How VIM Redefines Melting

To understand the benefits of a VIM furnace, you must first understand its two defining technologies: induction heating and vacuum operation.

Electromagnetic Induction Heating

The furnace operates without any direct contact or flame. An alternating current (AC) is passed through a copper coil, which generates a powerful, fluctuating magnetic field.

This magnetic field induces strong electrical eddy currents within the metal charge inside the crucible. The metal’s natural resistance to these currents generates intense, rapid, and uniform heat, causing it to melt from the inside out.

Crucially, these same electromagnetic forces create a constant, gentle stirring action throughout the molten bath.

The Power of the Vacuum

The entire melting process occurs inside a chamber where the air has been evacuated. This vacuum is the key to preventing unwanted chemical reactions at high temperatures.

By removing the atmosphere, you eliminate oxygen and nitrogen, which prevents the formation of oxide and nitride inclusions. This is critical for preserving expensive and reactive alloying elements like titanium, aluminum, and zirconium, which would otherwise be lost to oxidation.

The vacuum also helps pull dissolved gases, such as hydrogen and other volatile impurities, out of the molten metal, further purifying it.

The Three Pillars of VIM Advantage

The combination of induction heating and a vacuum environment delivers three primary categories of benefits that are critical for high-performance applications.

1. Unmatched Purity and Compositional Control

A VIM furnace offers the highest possible degree of control over the final product's chemistry. Because the vacuum prevents oxidation, you can achieve an extremely close compositional tolerance.

This allows for the melting of highly reactive alloys, such as titanium and superalloys, that cannot survive the harsh environment of an air-melt furnace. The result is a cleaner, stronger metal with significantly fewer non-metallic inclusions and defects.

2. Superior Alloy Homogeneity

The natural electromagnetic stirring action is a unique benefit of induction melting. It ensures that all alloying elements are distributed perfectly evenly throughout the molten bath.

This constant motion prevents elemental segregation, where heavier or lighter metals might separate. The final cast product is therefore completely homogenous, with consistent properties from top to bottom.

3. Enhanced Operational Efficiency and Safety

IGBT-based power supplies provide precise, automated control over temperature, pressure, and stirring. This high degree of process control improves reliability, repeatability, and overall productivity.

The system is also inherently safer for operators and better for the environment. With no combustion byproducts, there is no air or slag pollution. The controlled environment also allows for the safe removal of harmful volatile elements.

Understanding the Trade-offs

While powerful, VIM technology is not the solution for every application. Understanding its limitations is key to making an informed decision.

Higher Initial Investment

VIM furnaces are complex systems that include sophisticated vacuum pumps, power supplies, and control systems. This results in a significantly higher upfront capital cost compared to standard air-melt induction or arc furnaces.

Batch Processing Limitations

VIM furnaces are, by nature, batch processors. While this provides excellent flexibility for producing various alloys in different quantities, they are not designed for the continuous, high-volume output of commodity metals like a blast furnace. Their strength is in high-value, not high-tonnage, production.

Increased Maintenance Complexity

The vacuum systems, advanced IGBT electronics, and precise instrumentation require specialized knowledge for maintenance and troubleshooting. This can lead to higher long-term maintenance costs and a need for more skilled technicians compared to simpler furnace types.

Making the Right Choice for Your Goal

Deciding on a VIM furnace depends entirely on the metallurgical requirements of your final product.

- If your primary focus is ultimate metal purity and reactive alloys: VIM is the non-negotiable industry standard for aerospace, medical, and semiconductor-grade materials.

- If your primary focus is cost-sensitive, high-volume production of standard alloys: A traditional air-melt induction furnace or an electric arc furnace is a more economical and practical choice.

- If your primary focus is manufacturing diverse, high-value alloys with perfect consistency: The precise batch control and superior homogeneity of a VIM furnace make it the ideal technology.

Ultimately, investing in a VIM furnace is a decision to prioritize material quality and chemical precision above all else.

Summary Table:

| Benefit | Key Features |

|---|---|

| Unmatched Purity | Prevents oxidation, removes gases, ideal for reactive alloys like titanium and superalloys |

| Superior Homogeneity | Electromagnetic stirring ensures even element distribution, prevents segregation |

| Enhanced Efficiency | Precise IGBT control, automated processes, safer operation with no combustion byproducts |

Ready to elevate your metal melting with precision and purity? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our IGBT VIM furnaces can deliver superior results for your high-value alloy production!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification