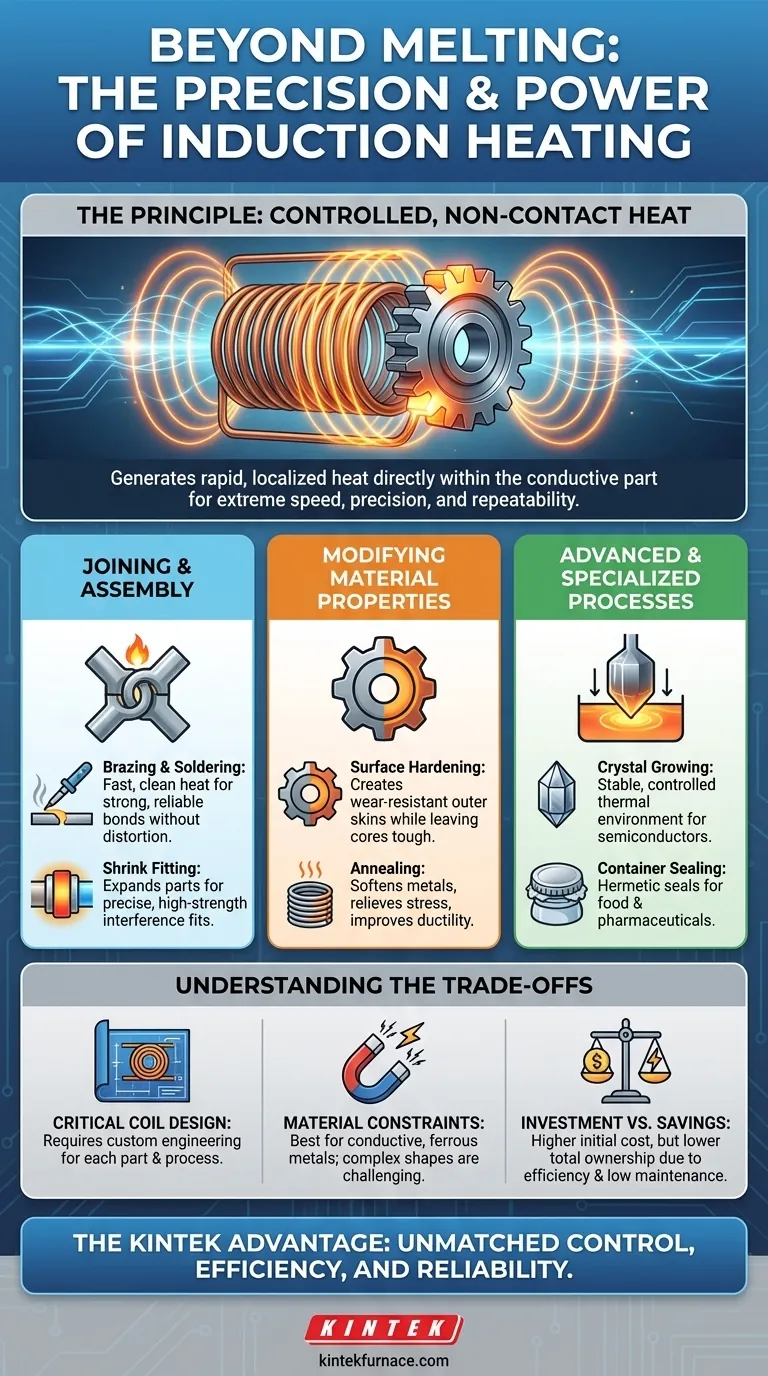

Beyond melting metals, induction heating is a highly versatile technology used for a wide range of precise industrial processes. Its core applications include joining components through brazing and soldering, modifying material properties via heat treating and hardening, and enabling high-precision assembly with processes like shrink fitting.

The true value of induction heating is not its ability to generate heat, but its power to deliver that heat with extreme speed, precision, and control. This pinpoint accuracy is what makes it an indispensable tool for so much more than just melting.

The Principle Behind the Versatility: Controlled Energy

The adaptability of induction heating stems from its unique method of energy transfer. It's a non-contact process that turns a specific part into its own heat source, giving operators an unparalleled level of control.

How Induction Heating Works

An induction system uses an alternating current passed through a carefully designed copper coil. This creates a powerful, oscillating electromagnetic field around the coil. When a conductive part is placed inside this field, it induces electrical currents (eddy currents) within the material, which generates rapid and localized heat.

The Power of Localization

Unlike a traditional furnace that heats an entire chamber, an induction coil only heats the portion of the material placed within its electromagnetic field. This allows you to harden a specific gear tooth without affecting the integrity of the gear's core, or braze a joint without damaging nearby sensitive components.

Unmatched Speed and Repeatability

The heating process is incredibly fast, often taking only seconds. Modern induction systems offer precise digital control over power, frequency, and cycle time. This ensures that every part is exposed to the exact same thermal profile, guaranteeing consistent, repeatable results essential for high-volume manufacturing and quality control.

A Spectrum of Industrial Applications

Because induction offers control over where and how heat is applied, it has been adopted across numerous industries for processes that require reliability and precision.

Joining and Assembly

Induction is ideal for joining metal components. By heating only the joint area, it creates strong bonds without distorting or weakening the entire assembly.

- Brazing & Soldering: Delivers fast, clean heat to the joint for a strong, reliable bond.

- Shrink Fitting: A shaft is chilled while a gear or bearing is heated with induction. The heated part expands, is fitted onto the shaft, and creates an incredibly strong interference fit as it cools and shrinks.

Modifying Material Properties

The most common use of induction outside of melting is heat treatment. By precisely managing heating and cooling cycles, you can fundamentally change a metal's metallurgical structure.

- Surface Hardening: Rapidly heats the surface layer of a part (like an axle or gear), which is then quenched. This creates a hard, wear-resistant outer skin while leaving the core ductile and tough.

- Annealing: Heats a metal to a specific temperature and allows it to cool slowly, which softens the material, relieves internal stresses, and improves its ductility.

Advanced and Specialized Processes

The precision of induction makes it suitable for highly technical and niche applications.

- Crystal Growing: In the semiconductor industry, induction provides the stable and highly controlled thermal environment needed to grow large, single-crystal silicon boules.

- Container Sealing: An aluminum foil seal inside a plastic cap is heated by induction after the cap is on the bottle. This melts a polymer layer on the foil, creating an airtight seal for food, beverage, and pharmaceutical products.

Understanding the Trade-offs

While powerful, induction heating is not a universal solution. Understanding its requirements is key to leveraging it effectively.

The Critical Role of Coil Design

The system's effectiveness is entirely dependent on the induction coil. The coil's shape, size, and number of turns must be engineered specifically for the part and the process. This means a new application often requires custom tooling, which represents an engineering and cost consideration.

Material and Geometry Constraints

Induction heating works best with electrically conductive materials, primarily ferrous metals like steel and iron. Furthermore, heating parts with highly complex or irregular geometries uniformly can be a significant challenge, sometimes requiring multiple coils or sophisticated part rotation.

Upfront Investment vs. Operational Savings

Induction systems can represent a higher initial capital investment compared to a simple convection furnace. However, they typically offer a lower total cost of ownership due to their high energy efficiency, reduced maintenance needs from having few moving parts, and minimal operational downtime.

Making the Right Choice for Your Process

To determine if induction is the right fit, align its capabilities with your primary manufacturing goal.

- If your primary focus is high-precision assembly: Induction's localized heating is perfect for joining or shrink-fitting parts without causing collateral heat damage.

- If your primary focus is improving material characteristics: Induction offers unmatched control over heating and cooling cycles for consistent hardening, tempering, or annealing results.

- If your primary focus is high-throughput, repeatable manufacturing: The speed and digital process control of induction ensure every part is produced to the exact same specification with minimal variance.

Ultimately, induction heating should be viewed as a tool of precision and control, not just one of brute thermal force.

Summary Table:

| Application | Key Benefits |

|---|---|

| Joining (Brazing, Soldering) | Strong bonds, no distortion, fast process |

| Heat Treating (Hardening, Annealing) | Controlled cycles, improved material properties |

| Assembly (Shrink Fitting) | High precision, interference fits |

| Specialized (Crystal Growing, Sealing) | Stable thermal control for niche uses |

| General Advantages | Speed, repeatability, energy efficiency |

Ready to enhance your industrial processes with precision induction heating? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories and industrial applications. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Whether you're focused on high-precision assembly, material property modification, or high-throughput manufacturing, our induction heating systems deliver unmatched control, efficiency, and reliability. Contact us today to discuss how we can optimize your operations and drive your success!

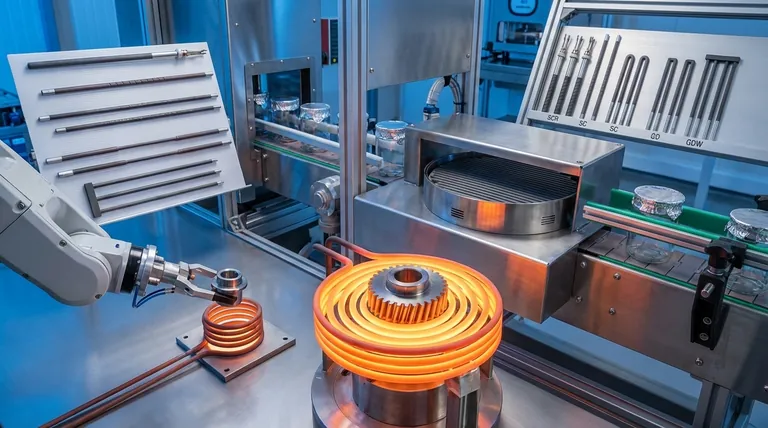

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance