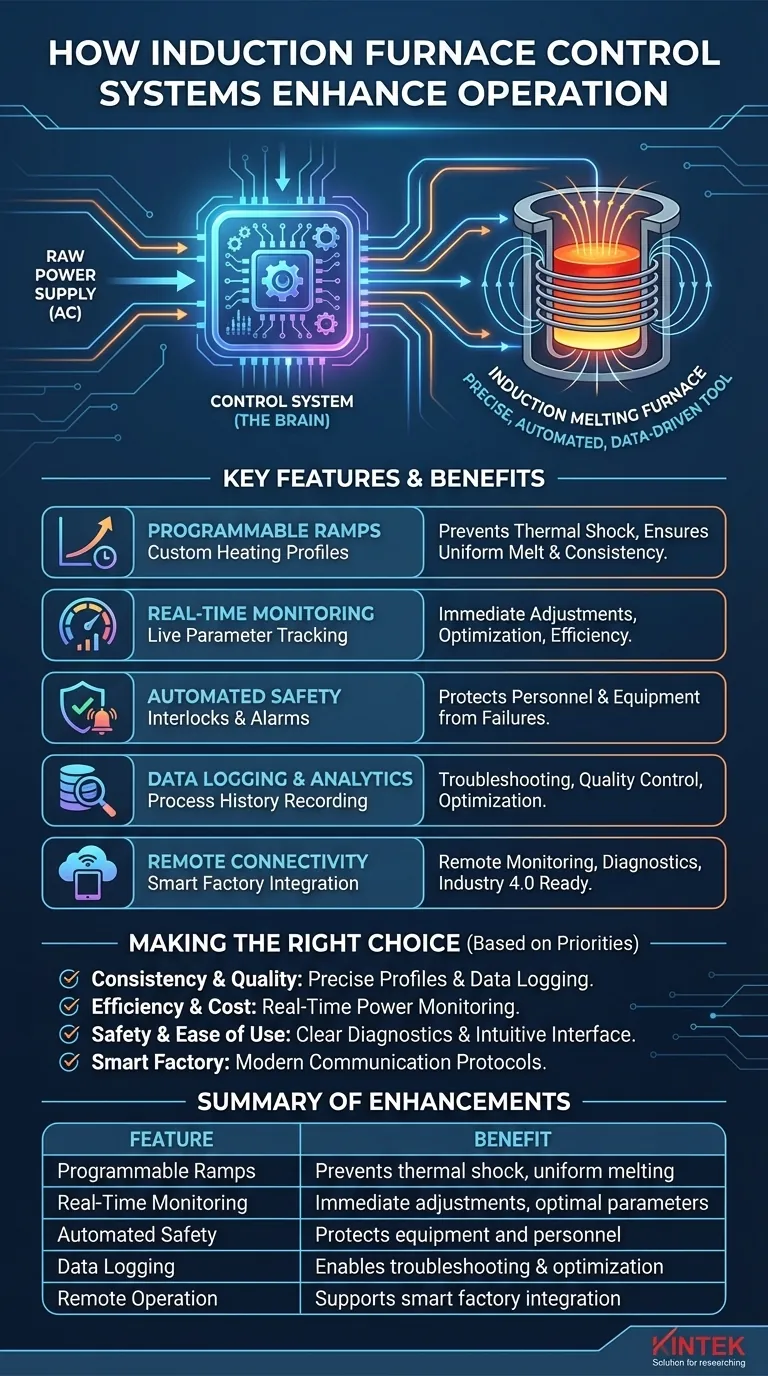

At its core, an induction furnace's control system enhances operation by transforming it from a brute-force heating device into a precise, automated, and data-driven metallurgical tool. By intelligently managing the flow of energy, it provides unparalleled control over the melting process, leading to significant improvements in efficiency, consistency, safety, and overall operational intelligence.

A modern control system acts as the brain of the furnace. It precisely manages the raw power of electromagnetic induction, ensuring every kilowatt of energy is used effectively to achieve a predictable, high-quality result while providing the data needed for continuous improvement.

From Raw Power to Precise Control

To understand the control system's value, we must first understand what it is controlling. The fundamental principle of an induction furnace is remarkably efficient but requires careful management.

The Physics of Induction Heating

An induction furnace uses a powerful alternating current (AC) flowing through a copper coil. This creates a rapidly changing magnetic field that penetrates the conductive metal charge inside. The magnetic field, in turn, induces powerful electrical currents—known as eddy currents—directly within the metal itself. The metal's natural resistance to these currents generates intense, precise heat, causing it to melt from the inside out.

The Role of the Control System

The control system's primary job is to govern the power supply that feeds the coil. It is not simply an on/off switch. It meticulously regulates the voltage, current, and frequency of the electricity. By doing so, it directly dictates the strength of the magnetic field and, therefore, the amount of heat generated in the metal at any given moment.

Key Features That Drive Performance

Modern control systems, often built on digital platforms like DSP or ARM processors, come equipped with features that provide tangible operational benefits.

Programmable Temperature and Power Ramps

Instead of applying full power immediately, operators can program specific heating profiles. This allows for a gradual increase in temperature, which is critical for preventing thermal shock to the furnace lining and ensuring a uniform melt. This programmability guarantees that every batch follows the exact same proven recipe.

Real-Time Monitoring and Feedback

An intuitive interface provides operators with a live dashboard of critical parameters. This includes the current melt temperature, power consumption (in kilowatts), and operational frequency. This constant feedback allows for immediate adjustments and ensures the process stays within optimal parameters.

Automated Alarms and Safety Interlocks

The system continuously monitors for abnormal conditions, such as overheating, cooling water failure, or electrical faults. If a dangerous threshold is crossed, it can trigger an alarm or automatically shut down the furnace, protecting both personnel and the equipment from catastrophic failure.

Data Logging for Process Optimization

The control system records every detail of every melt cycle. This historical data is invaluable for troubleshooting and quality control. If a batch has a defect, you can review the data logs to identify any deviation from the standard process. It allows you to analyze energy consumption per ton and refine melt recipes for maximum efficiency.

Remote Operation and Connectivity

Modern furnaces feature rich communication interfaces. This enables remote monitoring from a central control room or office and allows for remote diagnostics by the manufacturer. It is also the gateway to integrating the furnace into a "smart factory" or Industry 4.0 ecosystem, sharing data with plant-wide management systems.

Understanding the Trade-offs

While advanced control systems offer immense benefits, it is crucial to approach them with a clear understanding of the associated considerations.

Initial Investment vs. Long-Term ROI

A furnace with a sophisticated, feature-rich control system carries a higher upfront cost. This investment must be weighed against the long-term return, which comes from lower energy bills, reduced scrap rates, improved product consistency, and potentially lower labor costs through automation.

Complexity vs. Capability

Greater capability often comes with greater complexity. While a powerful system can do more, it may require more training for operators and maintenance staff. An intuitive user interface is not a luxury; it is essential to ensure the system's advanced features are actually used effectively.

Reliance on Digital Systems

All-digital software is powerful but introduces a dependency on the system's reliability. It's critical to ensure the system is robust, well-tested, and supported by the manufacturer. While more reliable than older analog systems, a software failure can halt production just as effectively as a mechanical one.

Making the Right Choice for Your Operation

The ideal control system depends entirely on your operational priorities.

- If your primary focus is consistency and quality control: A system with precise, programmable melt profiles and comprehensive data logging is non-negotiable.

- If your primary focus is operational efficiency and cost reduction: Prioritize a system with detailed, real-time power monitoring to optimize energy usage throughout the entire melt cycle.

- If your primary focus is safety and ease of use: Look for a system with a clear diagnostic display, robust safety interlocks, and a highly intuitive operator interface.

- If your primary focus is integration into a smart factory: Ensure the control system has modern communication protocols (like Ethernet/IP or Profinet) for seamless data exchange.

Ultimately, the right control system elevates your melting process from a manual art to a data-driven science.

Summary Table:

| Feature | Benefit |

|---|---|

| Programmable Temperature Ramps | Prevents thermal shock, ensures uniform melting |

| Real-Time Monitoring | Allows immediate adjustments, maintains optimal parameters |

| Automated Safety Interlocks | Protects equipment and personnel from failures |

| Data Logging | Enables troubleshooting and process optimization |

| Remote Operation | Supports smart factory integration and remote diagnostics |

Ready to enhance your metal melting operations with a high-performance induction furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our expertise can boost your efficiency, consistency, and safety!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity